Surface thread controller of sewing machine

A technology of holding device and sewing machine, which is applied to the thread cutting mechanism, sewing machine components, sewing equipment and other directions in the sewing machine, can solve the problems of reducing production efficiency, unstable length of the end of the upper thread, lengthening the length, etc. product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

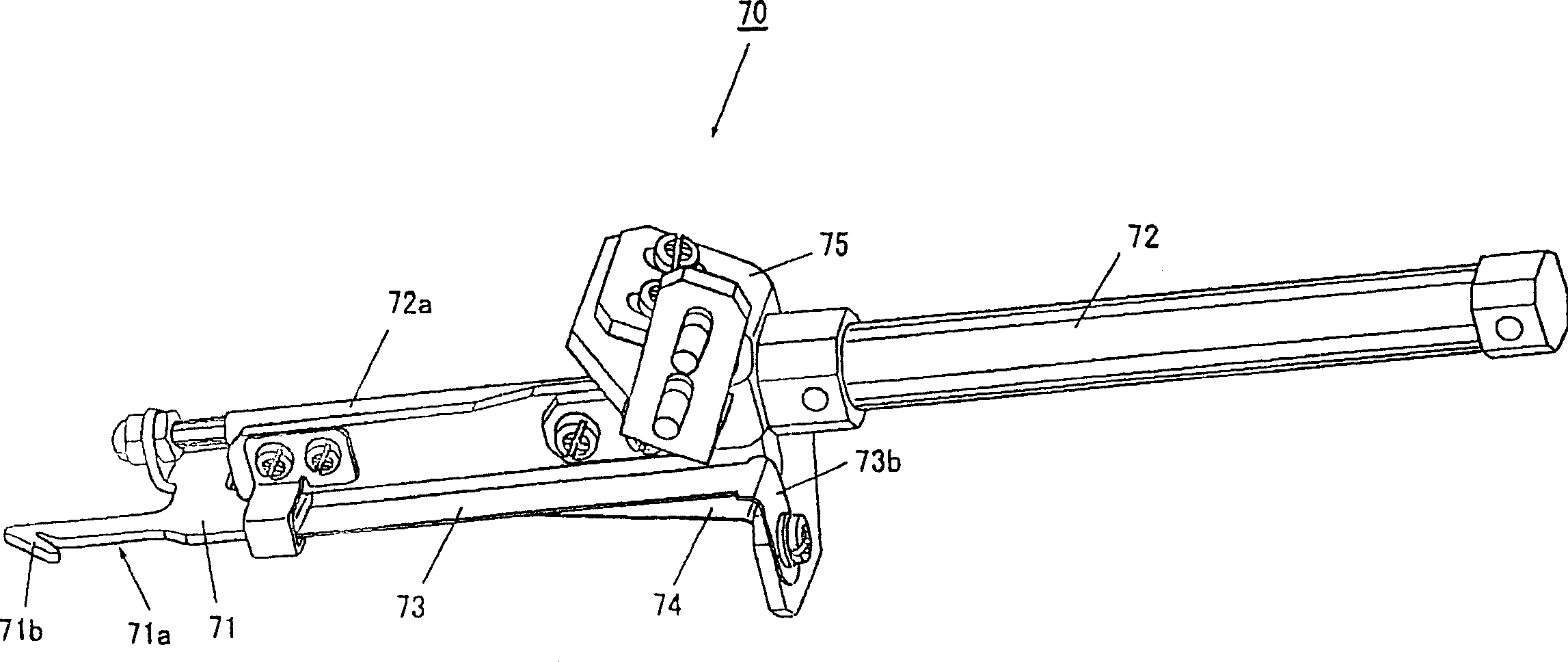

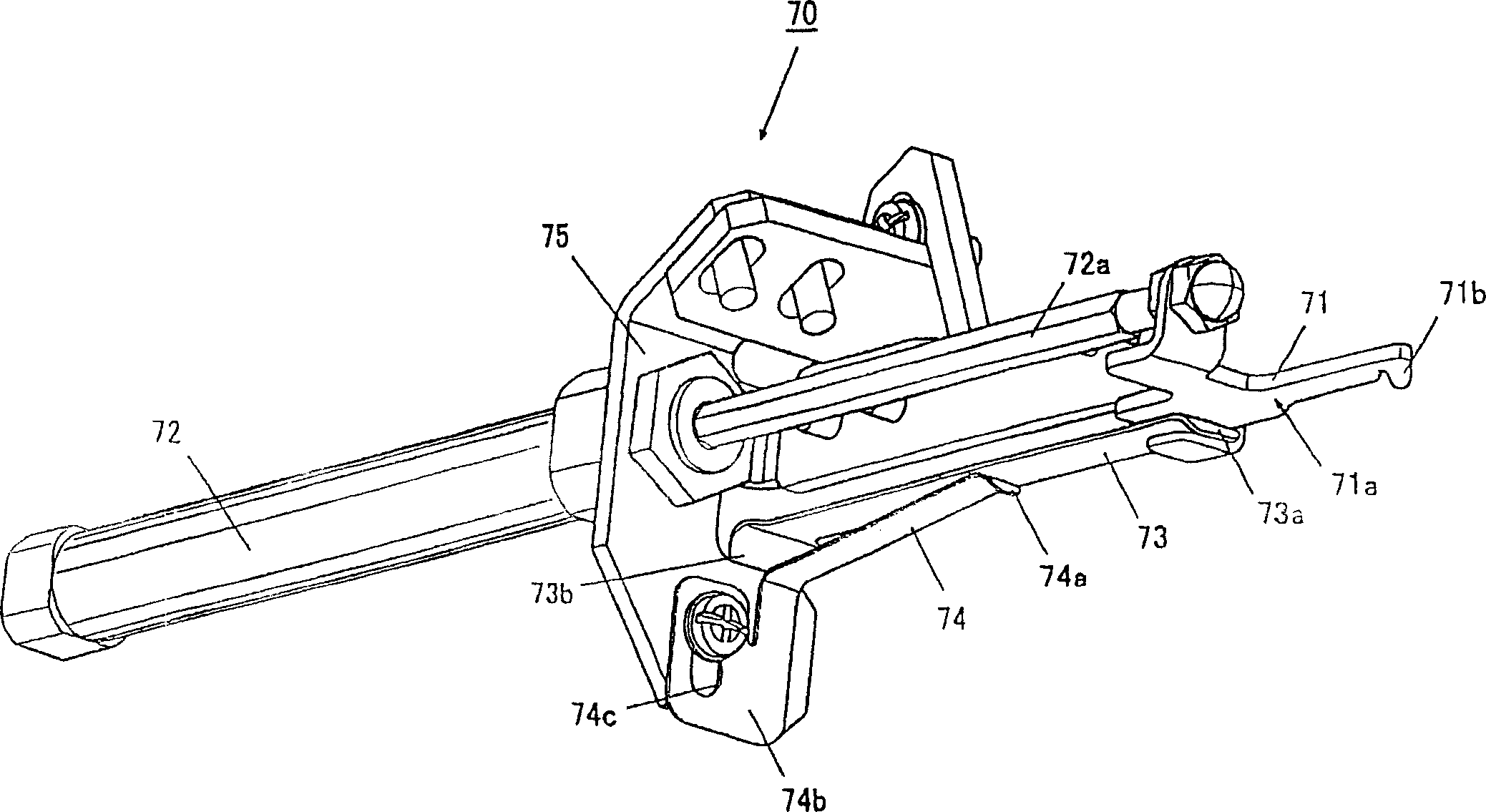

[0045] Below, refer to Figure 1 to Figure 6 The upper thread holding device of the button sewing machine according to the embodiment of the present invention will be described.

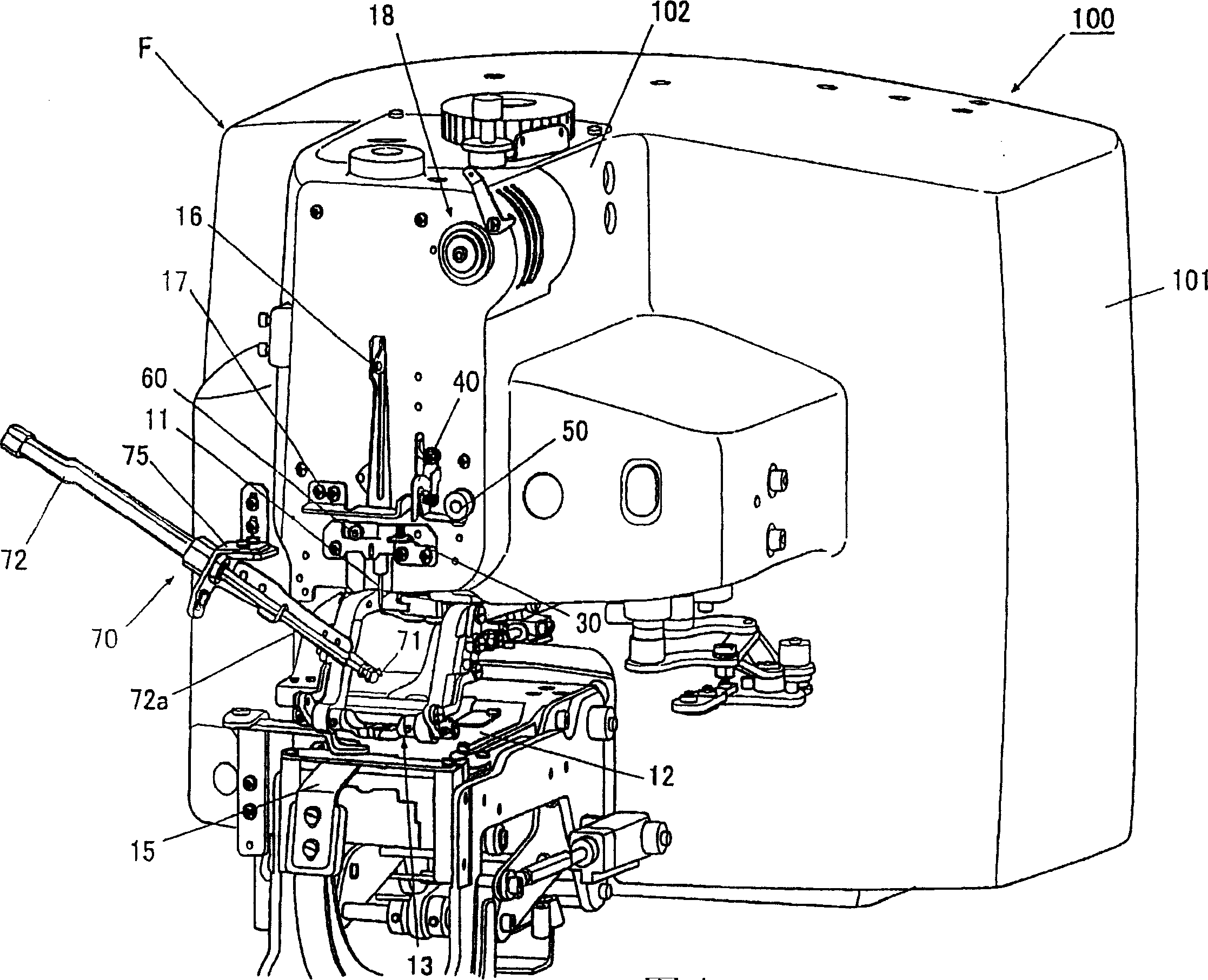

[0046] figure 1 It is a perspective view of the main structure of the button sewing machine 100.

[0047] The button sewing machine 100 sews a button on a cloth with a sewing thread T serving as an upper thread through the cooperation of a vertically moving needle 11 and a rotary hook (not shown).

[0048] Button sewing machine 100, its whole is by being positioned at its bottom sewing machine base plate (illustration omitted), the sewing machine vertical body portion 101 that is vertically provided upwards from one end portion behind the sewing machine base plate, and the vertical sewing machine body portion 101 along the top of the sewing machine body portion 101. The sewing machine head 102 extending above the sewing machine base plate is constituted, and its outline formed by them is substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com