Terminal aldehyde polyoxyethylene-diethyl pentetic acid block polymer and its synthesizing method

A technology of diethylenetriaminepentaacetic acid block and aldehyde-terminated polyoxyethylene, which is applied in the fields of medical science and chemical synthesis, can solve the problems of long half-life and slow elimination speed, and achieve long half-life, prolonged residence time, biophase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

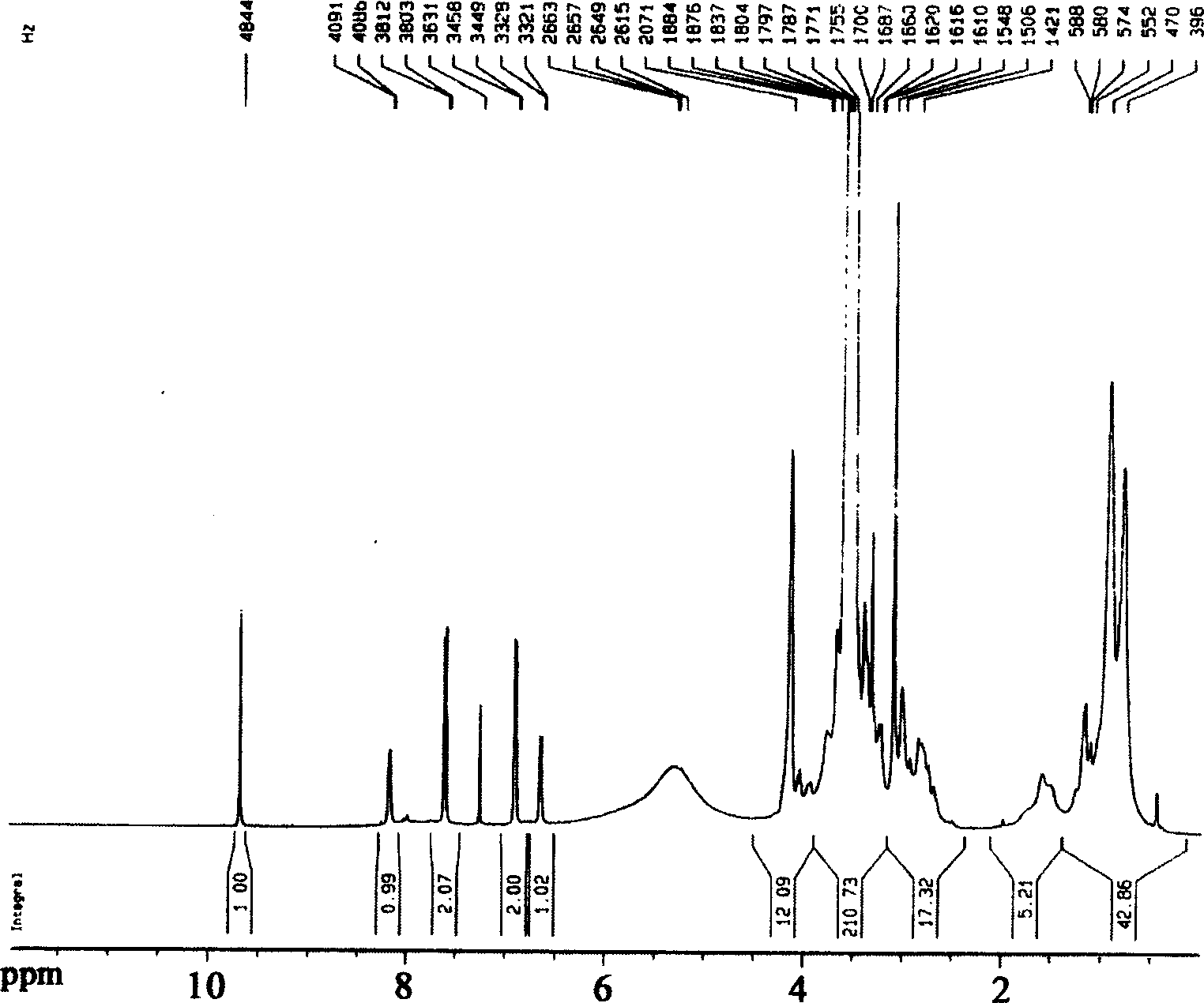

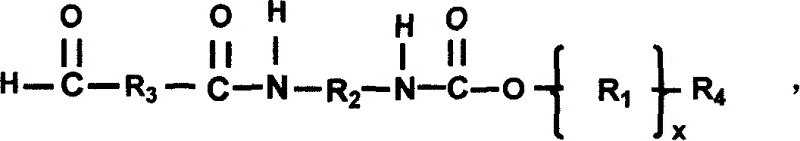

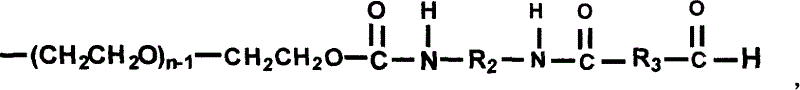

Method used

Image

Examples

Embodiment 1

[0056] The first step isocyanate-terminated polymer preparation

[0057] First, the raw material of the present invention, the hydroxyl-terminated poly Oxyethylene-diethylenetriaminepentaacetic acid block polymer (n=18, x=1, average molecular weight is 1960), other raw materials: diisocyanate is isophorone diisocyanate (IPDI), catalyst is dilauric acid Dibutyltin, the solvent is dichloromethane;

[0058] Then, the amount of polyoxyethylene-diethylenetriaminepentaacetic acid block polymer, isophorone diisocyanate, dibutyltin dilaurate and methylene chloride added in amounts of 3g, 0.68g, and 0.06g respectively And 40g, according to the polyoxyethylene-diethylenetriaminepentaacetic acid block polymer of terminal hydroxyl: isophorone diisocyanate: dibutyltin dilaurate: the weight ratio of dichloromethane is 1: 0.227: 0.02: 13.3 Measured, reacted at 40°C for 3 hours under stirring to obtain 3.68 g of isocyanate-terminated polymer;

[0059] Synthesis of crude product of terminal...

Embodiment 2

[0063] In the first step, n=18, x=1, and the average molecular weight of the polyoxyethylene-diethylenetriaminepentaacetic acid block polymer of the hydroxyl-terminated raw material synthesized according to Example 1 are 1160, and the other raw material diisocyanate is isophorone Diisocyanate (IPDI), the catalyst is dibutyltin dilaurate, the solvent is dichloromethane, hydroxyl-terminated polyoxyethylene-diethylenetriaminepentaacetic acid block polymer, isophorone diisocyanate (IPDI), dilauric acid The addition amount of dibutyltin dichloride and dichloromethane is respectively 3g, 0.57g, 0.06g and 12g, the polyoxyethylene-diethylenetriamine pentaacetic acid block polymer of terminal hydroxyl, isophorone diisocyanate, dilauric acid The weight ratio of dibutyltin to dichloromethane is 1: 0.19: 0.02: 4, and reacted for 3 hours at 40° C. with stirring to obtain 3.57 g of isocyanate-terminated polymer;

[0064] Synthesis of crude product of terminal aldehyde group polymer in the s...

Embodiment 3

[0068] In the first step, the polyoxyethylene-diethylenetriaminepentaacetic acid block polymer of the hydroxyl-terminated raw material synthesized according to Example 1 has n=45, x=1, an average molecular weight of 4350, and the diisocyanate is isophorone diisocyanate (IPDI), the catalyst is dibutyltin dilaurate, the solvent is dichloromethane, the addition of polyoxyethylene-diethylenetriaminepentaacetic acid block polymer, IPDI, dibutyltin dilaurate and dichloromethane Be respectively 13.06g, 1.39g, 0.06g and 150g, the weight ratio of polyoxyethylene-diethylenetriaminepentaacetic acid block polymer, IPDI, dibutyltin dilaurate and methylene chloride of terminal hydroxyl is 1: 0.106: 0.00459:11.49, reacted at 55°C for 5 hours under stirring to obtain 14.45 g of isocyanate-terminated polymer;

[0069] The second step hydroxy aldehyde compound is p-Hydroxybenzaldehyde, the polymer of terminal isocyanate group and the consumption of p-Hydroxybenzaldehyde are 14.45g and 0.7321g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com