Fuel hose arrangement for liquefied petroleum ejecting engine

A technology of liquefied petroleum and engines, applied in the direction of engine components, combustion engines, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

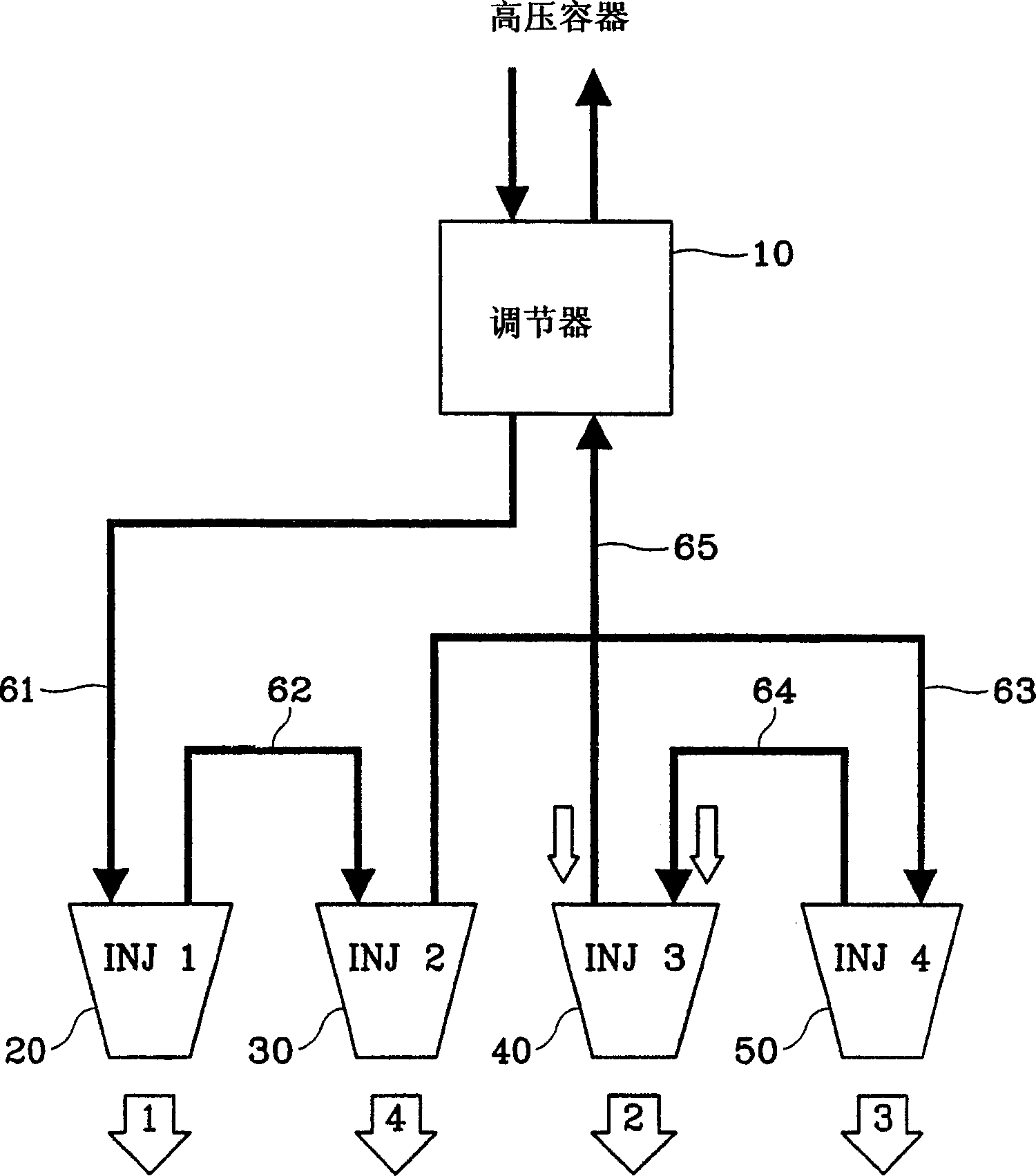

[0014] The preferred embodiment of the invention is used in a Liquefied Petroleum Injection (LPI) engine with four injectors arranged in a row. refer to figure 1 , the fuel supply system of the LPI engine includes a regulator 10, a first injector 20, a second injector 30, a third injector 40, a fourth injector 50 and a fuel hose 61 connected to the above components, 62, 63, 64, 65.

[0015] The regulator 10 keeps Liquefied Petroleum Gas (LPG), which is delivered by a pump at high pressure from a high-pressure vessel, at 5-10 bar at all times. The first to fourth injectors 20 to 50 are arranged consecutively, and in the order of the first injector 20, the third injector 40, the fourth injector 50 and the second injector 30 according to the control of the engine ECU Inject fuel.

[0016] The first fuel injector 20 receives fuel from the regulator 10 through the fuel hose 61 . The second fuel injector 30 receives fuel from the first fuel injector 20 through the second fuel ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com