Tube shaped electrical machine via non-electromagnetic force to release brake

A tubular motor, electromagnetic force technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increased cost, short service life, many parts and so on, and achieve increased production cost, long service life and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

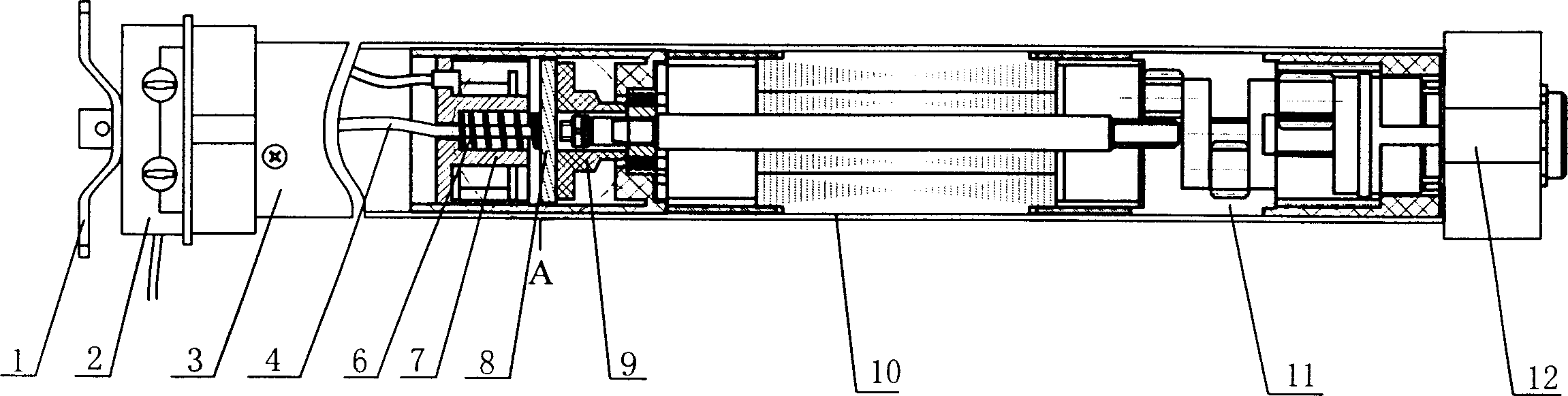

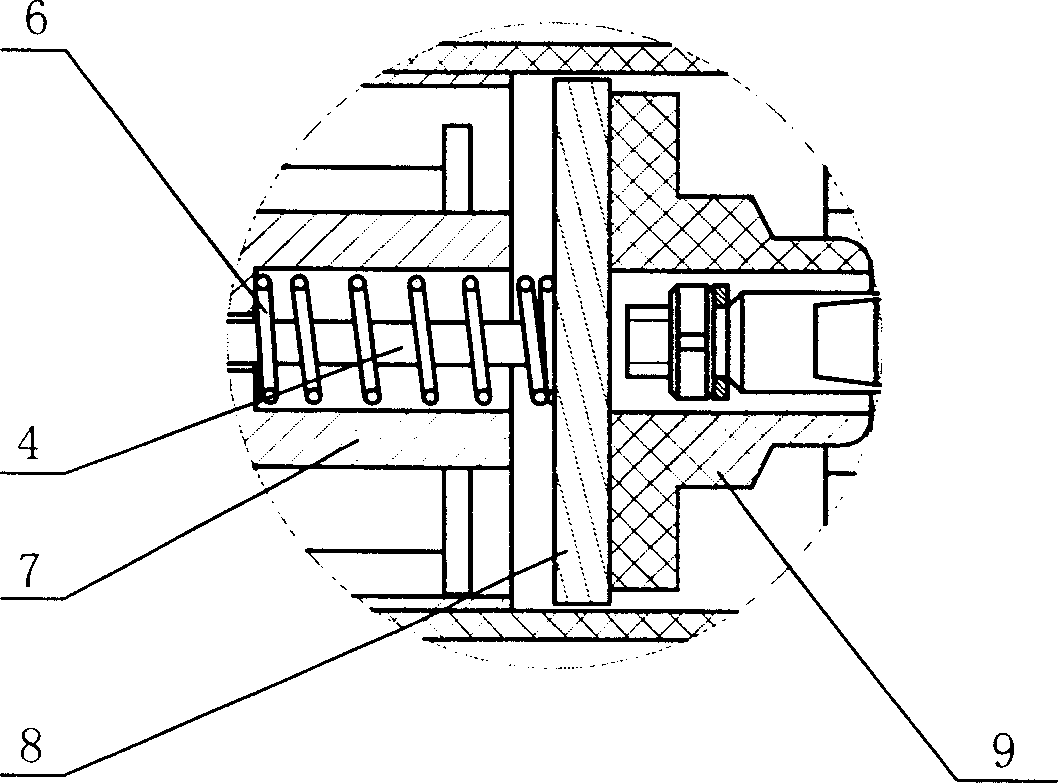

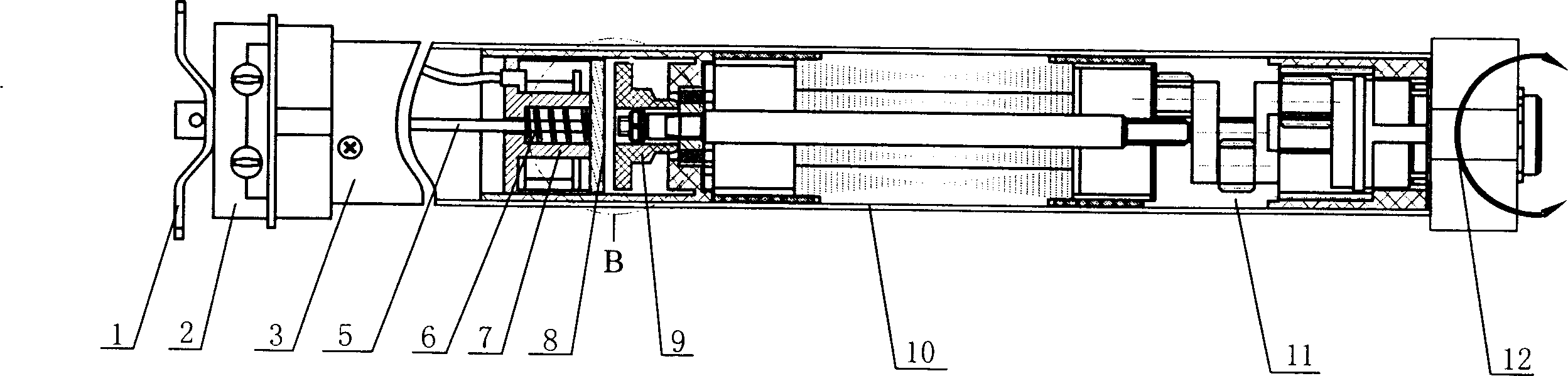

[0021] Such as figure 1 As shown, a tubular motor that can disengage the brake through non-electromagnetic force includes a mounting plate 1 for fixing to the wall, a machine base 2, a casing 3, and a drive motor 10 placed in the casing 3, a speed reduction device 11, Output shaft 12 and braking device, braking device comprises electromagnet 7, the spring 6 that is fixed on the electromagnet 7, the brake pad 8 that links to each other with spring 6 and the brake disc 9 corresponding with brake pad 8, drive motor 10 one end and brake disc 9 are matched and connected, and the other end is connected with the output shaft 12 through the reduction gear 11. The brake device is provided with a traction device, one end of the traction device passes through the electromagnet 7 and the spring 6 and is connected to the brake pad 8, and the other end leads out of the shell 3 of the tubular motor.

[0022] figure 1 , figure 2 Shown is an embodiment of the present invention. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com