Screen and method for manufacturing the same

A manufacturing method and technology of display screen, applied in the field of display screen, can solve problems such as unsatisfactory improvement of contrast ratio and delay, and achieve the effect of improving contrast ratio and improving visual characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

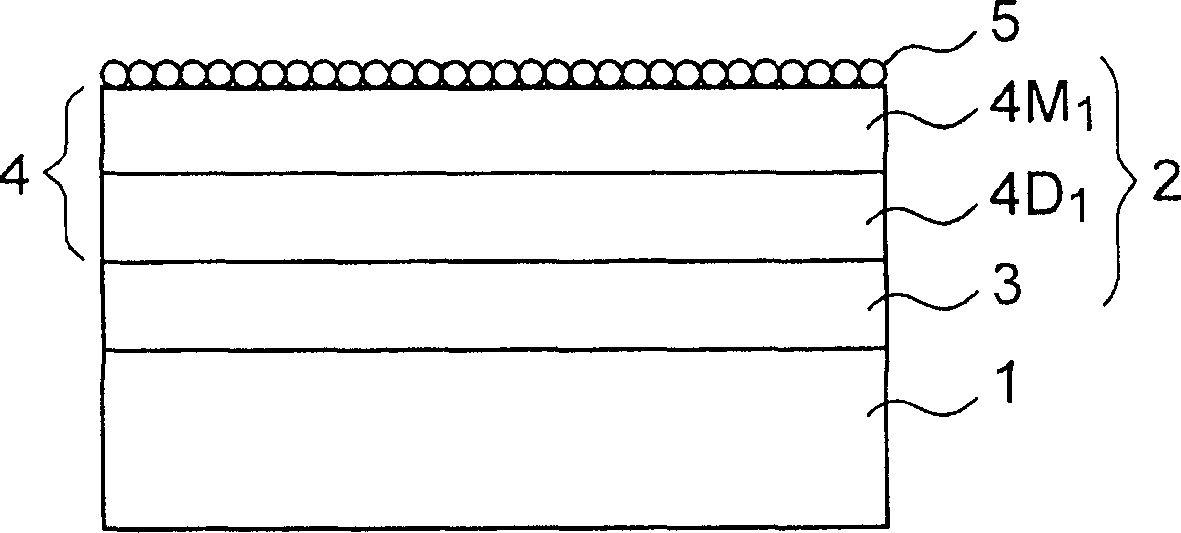

[0065] figure 1 A display screen according to the first embodiment of the present invention is shown, wherein a substrate 1 is formed on a substrate 1 to reflect light in a specific wavelength region, such as RGB three primary color wavelength regions, and to absorb light in a wavelength region other than the specific wavelength region. Light selective reflection layer 2, metal thin film 3 and dielectric film 4D i (i=1, 2, ...) and light-absorbing film 4M with transmittance j (j=1, 2, . . . ) optical multilayer film 4, and a diffusion layer 5 is further formed on the selective reflection layer to scatter the light reflected by the selective reflection layer 2.

[0066] The substrate 1 supports the display screen, and various materials can be used for the substrate. When imparting flexibility to the display screen, for example, a plastic film having a thickness on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com