Waste water treatment agent for novel gravure note printing

A wastewater treatment agent and treatment agent technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of operator injury, large sediment viscosity, high treatment cost, reduce treatment cost, improve treatment efficiency, suspended solids low content effect

Inactive Publication Date: 2006-02-22

SHANGHAI BANKNOTE PRINTING +1

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 2. The exothermic reaction of sulfuric acid in the process of adjusting pH is difficult to control. The violent chemical reaction will cause the overflow of waste water, seriously affect the working environment, and bring certain

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to waste water treatment agent particular to gravure waste water, which comprises: iron coagulant 10-60%, dispersant 5-30%, defoaming agent 1-10%, cosolvent 3-5%, and water. The formulation brings well coagulate effect to ink-contained waste water from product or ultrafiltration. The mud-water can be separated by pressure filter. This agent has stable water-phase, well compatibility with waste water.

Description

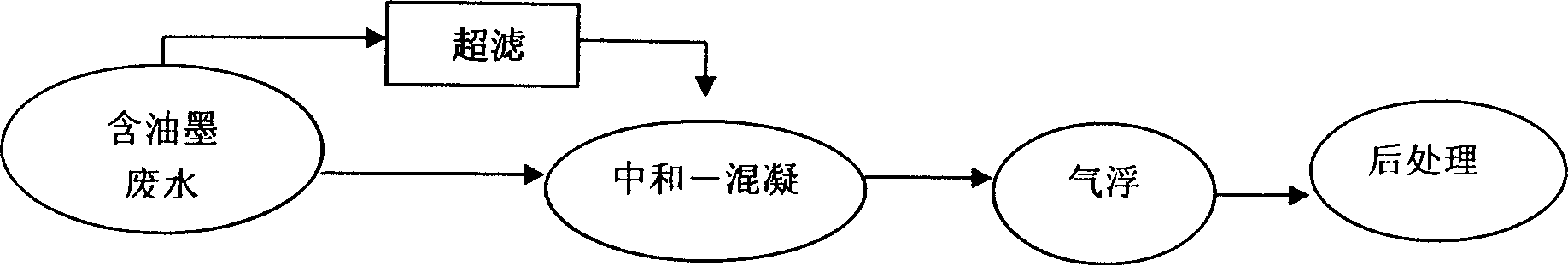

technical field [0001] The invention relates to a wastewater treatment agent, in particular to a banknote printing gravure wastewater treatment agent and a treatment method. Background technique [0002] In the banknote printing process, the ink-containing wastewater formed by the wiping solution cleaning the color die roller is one of the difficulties faced by the banknote printing industry. Main components of this wiping solution: sodium hydroxide 1.0-1.2%, surfactant about 0.5%, demineralized water and other additives 98.3%-98.5%; main components of ink-containing wastewater: pigments, fillers, binders, resin oil class, surfactants and sodium hydroxide. [0003] At present, the more feasible treatment process is as follows: see Figure 1, after the ink-containing wastewater is neutralized, coagulated, and ultra-filtered, it is air-floated and finally post-treated. In the neutralization and coagulation section, about 50% sulfuric acid is basically used to adjust the pH of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/52

Inventor 吴亚复郁学云张蔚恒倪铁军刘昕项鹏

Owner SHANGHAI BANKNOTE PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com