Fallow crop rotation, wind-proofing and moisture-preserving method for cultivating corn

A technology of corn and wind protection, applied in the direction of soil preparation, soil lifting machinery, agricultural machinery and tools, etc., can solve the problems of soil fertility not being restored, soil quality reduction, soil quality deterioration, etc., to prevent soil wind erosion and protect soil The effect of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] After the autumn harvest, the ground is raked with machinery for sowing in the spring of the following year. Before sowing, use a compass to orient the sowing ridge to 15-20 degrees south-south west.

[0016] 1. The first year of farming

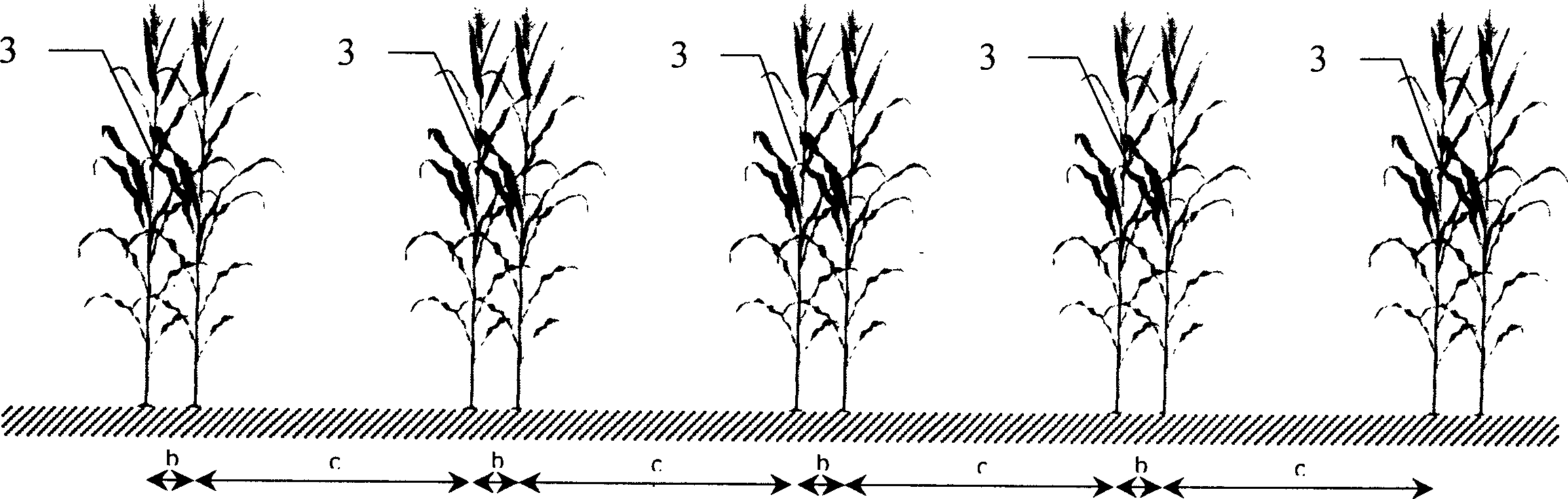

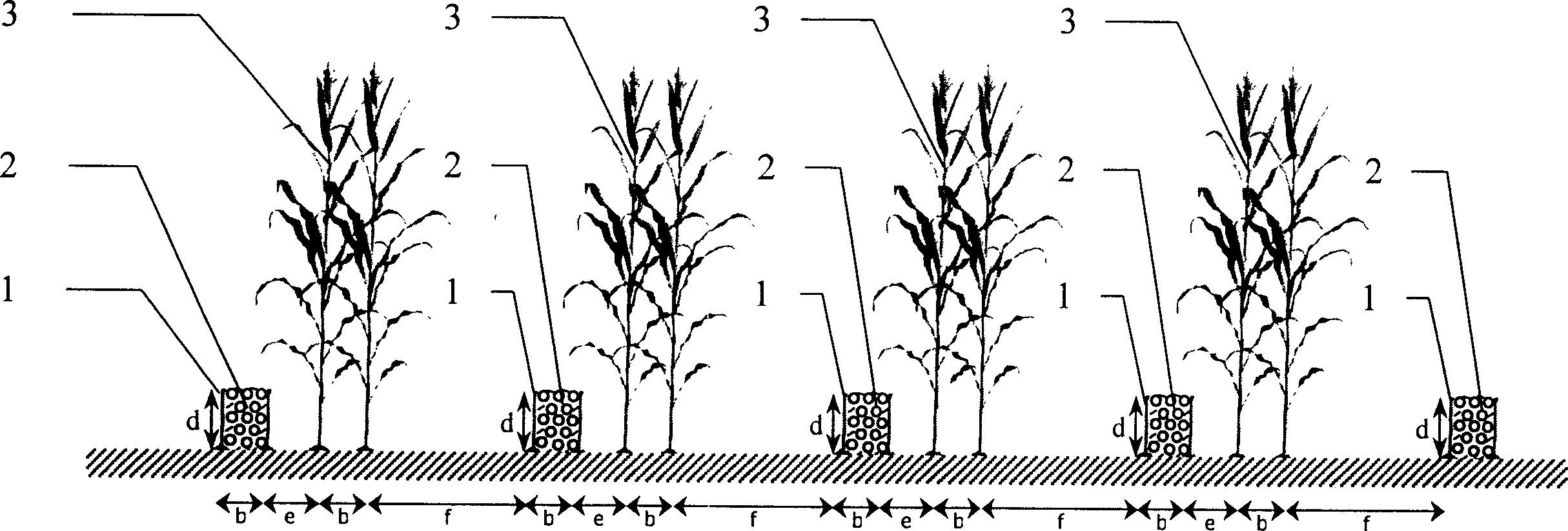

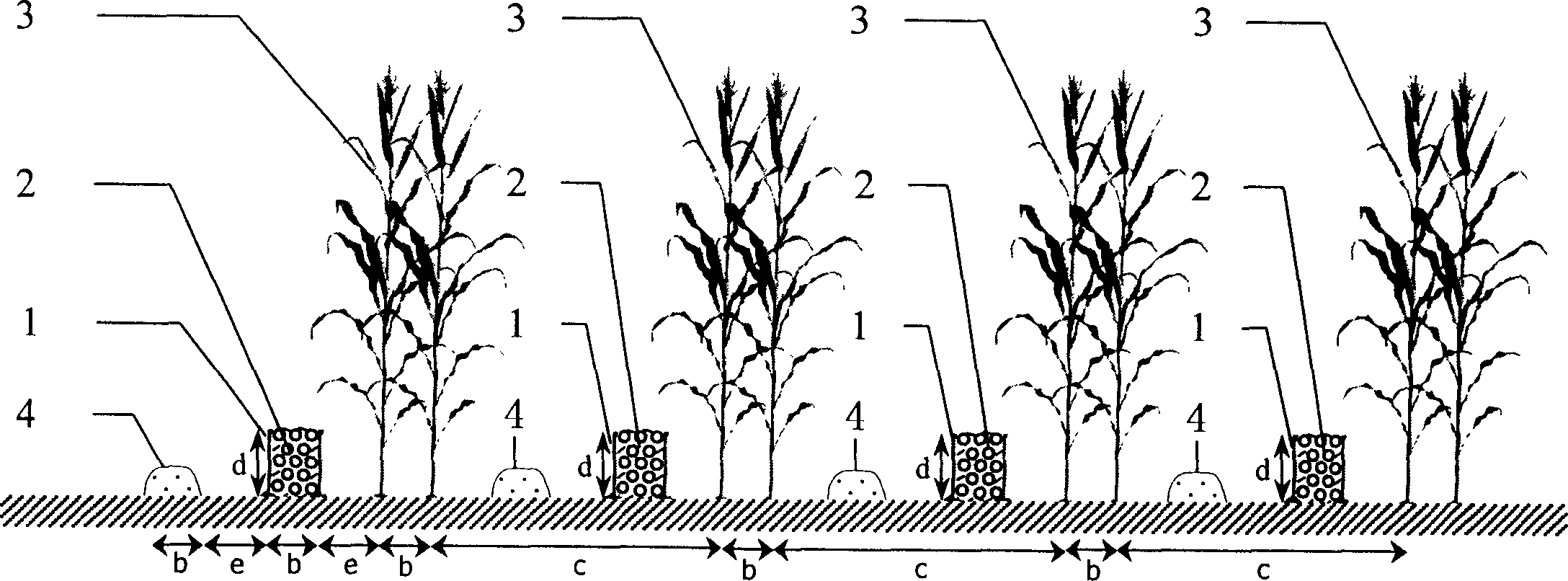

[0017] Such as figure 1 As shown, the ridge spacing is set to be 1.7 meters for the large ridge spacing c and 0.3 meters for the small ridge spacing b, forming a 2-meter 2-row combination ridge. After the ridge distance is set, ordinary seeders can be used for sowing without special machinery.

[0018] According to the characteristics of corn varieties, such as the growth characteristics of dense-resistant, semi-dense-resistant, and flat-type corn, determine the number of plants per hectare. 14 cm, 13 cm, 11 cm, 60,000, 70,000 and 80,000 to 90,000 seedlings per hectare, to ensure that all seedlings emerge at one time, and the yield of more than 25,000 jin can be obtained under reasonable field management.

[0019] When harvesting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com