Vacuum regulating valve

A pressure regulating valve and vacuum technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problem of driving the retaining ring by a small motor, and achieve the effects of miniaturization, power saving, and excellent economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

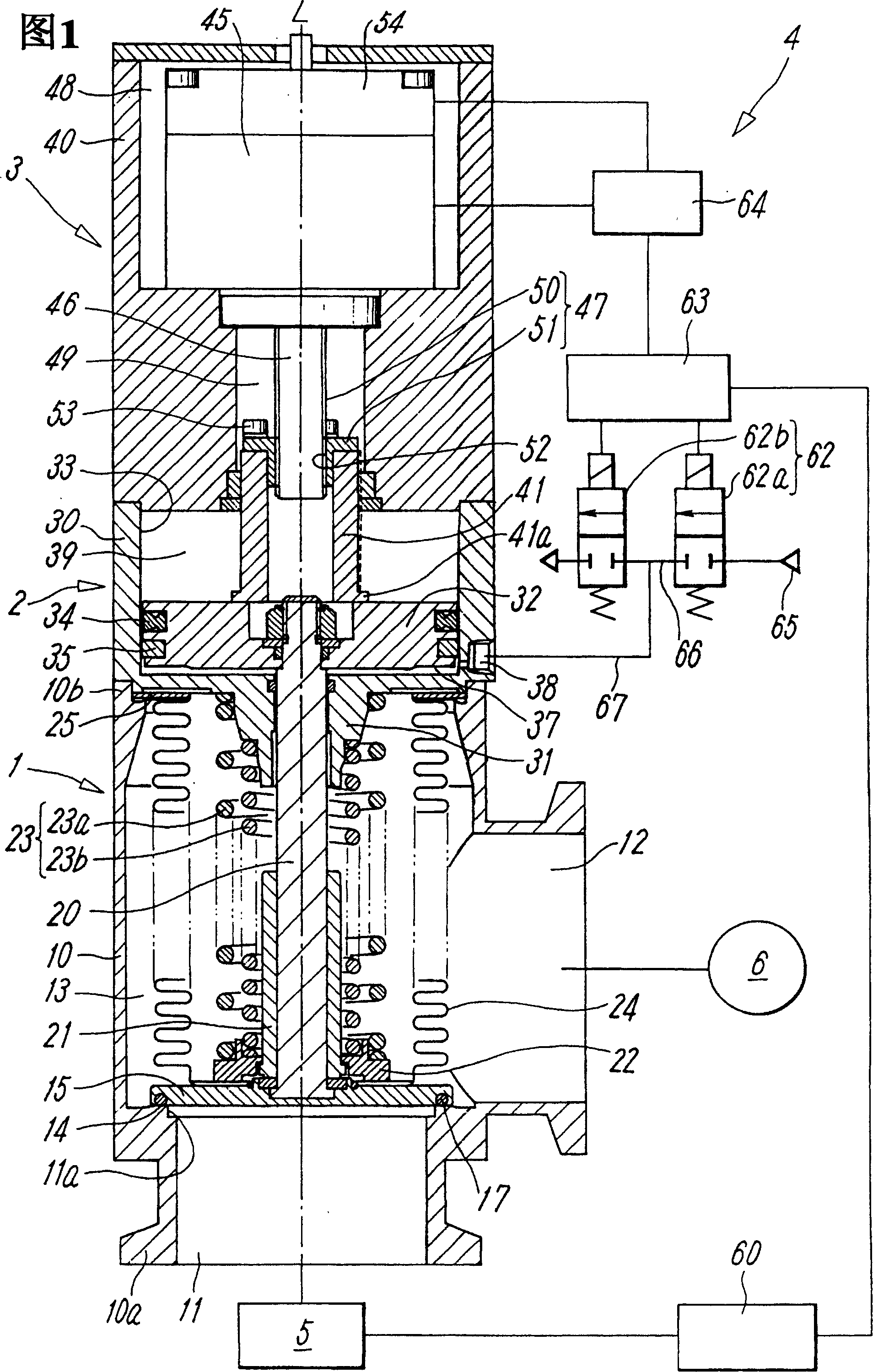

[0024] Fig. 1 shows a preferred representative embodiment of the vacuum pressure control valve of the present invention. This valve consists of a valve main body 1 having a valve member 15 for opening and closing the flow path 13 between the main gas ports 11 and 12; The cylinder part 2 of the valve member 15; the valve opening adjustment part 3 for setting the opening degree of the above-mentioned valve member 15; The valve main body 1, the cylinder 2 and the valve opening adjustment part 3 are connected in series along the axis L of the valve.

[0025] The above-mentioned valve body part 1 essentially has a cylindrical or prism-shaped hollow valve casing 10, on which a first main gas port 11 for connecting with the vacuum chamber 5 is arranged, and for connecting with the vacuum chamber 5. The second main air port 12 connected to the vacuum pump 6, the above-mentioned first main air 11, is on the side of the first end 10a of the valve housing 10, and opens in the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com