Internal combustion engine and lubrication system thereof

An internal combustion engine, lubrication system technology, applied in the direction of engine lubrication, combustion engine, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

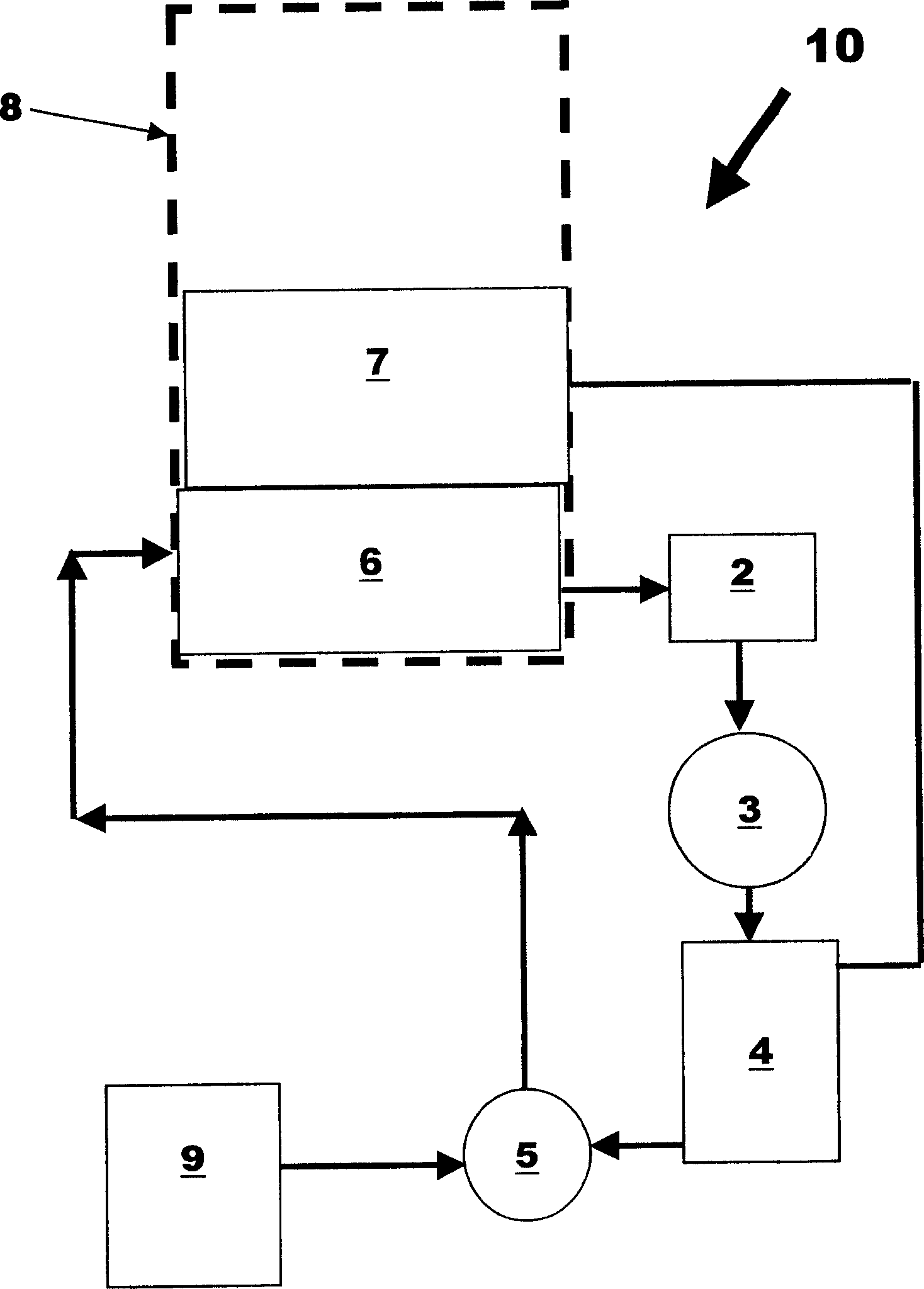

[0037] Special reference below figure 1 The invention is described, figure 1 A motor vehicle 10 is shown having an internal combustion engine 8 . Engine 8 includes a crankcase 7 and a main oil storage container or sump 6 .

[0038] The engine 8 is equipped with a lubrication system for lubricating not only the various moving parts of the engine 8 but also the turbocharger 3, which is operatively connected to the exhaust manifold (not shown) of the engine 8 to provide Improved internal combustion engine performance.

[0039] The lubrication system comprises: an oil pump 2 for pumping lubricant in the form of oil from the main oil reservoir 6 to the turbocharger 3 and in particular to the bearings of the turbocharger 3; the secondary oil reservoir 4 that receives the oil from the turbocharger bearings; and the engine-driven vacuum pump 5 for providing a partial vacuum within the secondary oil reservoir 4, thereby pushing the oil from the turbocharger bearings to the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com