Motorcycle auxiliary shaft assembly

A motorcycle and countershaft technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of no reverse gear function, unreasonable setting, poor lubrication effect, etc., to reduce wear and tear, Smooth operation and the effect of reverse gear function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

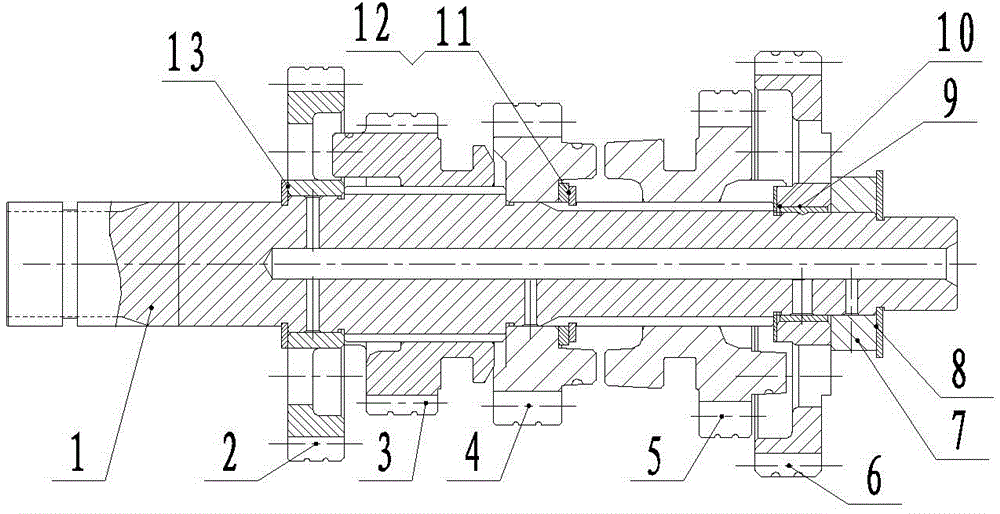

[0012] like figure 1 As shown, the motorcycle countershaft assembly of this embodiment, the motorcycle countershaft assembly, includes a countershaft 1, and the countershaft 1 is sequentially sleeved with a countershaft second-speed gear 2 and a countershaft fifth-speed gear 3 from left to right , reverse driven gear 4, countershaft third gear 5 and countershaft first gear 6, the left end of the countershaft second gear 2 is positioned by the thrust washer IV13, the right end is positioned by the countershaft shoulder, the countershaft five The gear 3 is combined with the countershaft 1 through a spline, the left end of the reverse driven gear 4 is positioned through the shoulder of the countershaft, the right end is positioned through the spline washer 12 and the thrust washer III11, and the first gear 6 of the countershaft is positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com