Aluminium-nickel metal welding bond and process for preparing the same

A technology of metal welding and welding strips, applied in the direction of metal layered products, chemical instruments and methods, lamination devices, etc., can solve problems such as technical difficulties that cannot be solved, and achieve the effect of low cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

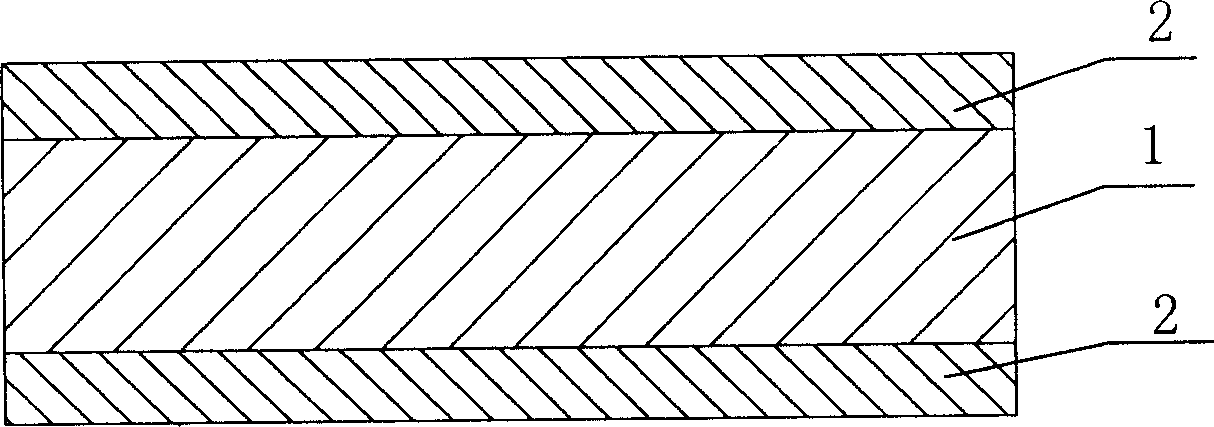

[0021] Such as figure 1 , shows an aluminum-nickel metal welding strip, the welding strip includes an aluminum thin strip 1 and a nickel thin strip 2 connected by fusion welding, the aluminum thin strip 1 and the nickel thin strip 2 are stacked to form a three-layer alternating interlayer structure, and the welding Both the uppermost and the lowermost layers of the strip are nickel thin strips 2 . The thickness of the thin nickel strips 2 on different levels is equal to 0.05mm. , the thickness of the aluminum strip 1 is 0.15 mm. .

[0022] The nickel thin strip 2 is made of pure nickel, and the aluminum thin strip is made of alloy aluminum with an aluminum content greater than 95%.

Embodiment 2

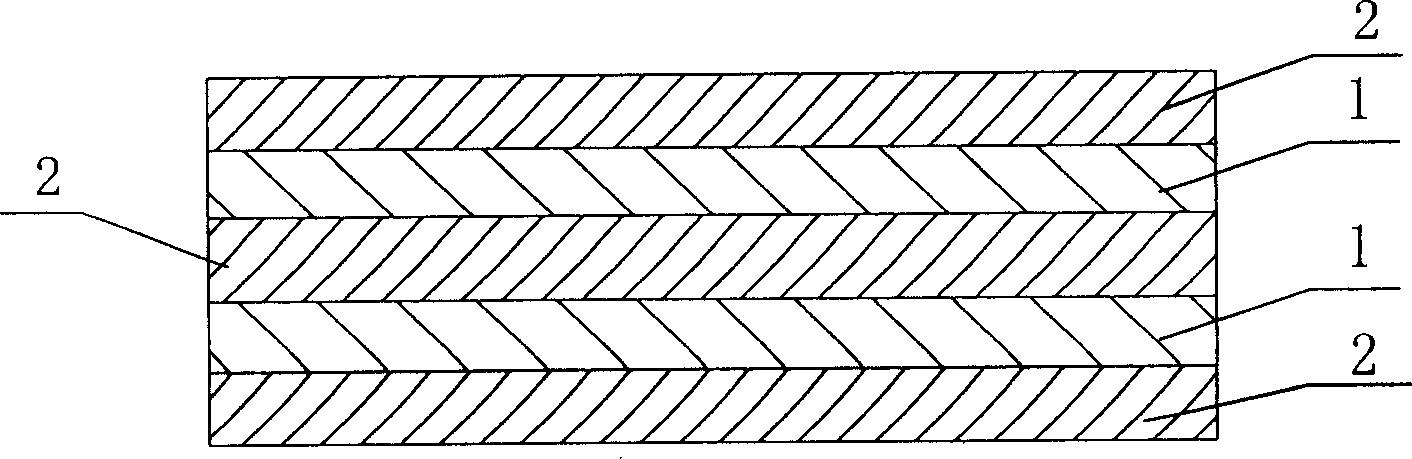

[0024] Such as figure 2 , shows an aluminum-nickel metal welding strip, the welding strip includes an aluminum thin strip 1 and a nickel thin strip 2 connected by fusion welding, the aluminum thin strip 1 and the nickel thin strip 2 are stacked to form a five-layer alternating interlayer structure, and The uppermost layer and the lowermost layer of the welding strip are nickel thin strips 2 .

[0025] The nickel strips 2 on the uppermost and lowermost layers have a thickness of 0.1 mm. The thickness of the thin aluminum strip 1 on the second upper layer and the second lower layer is 0.1mm, and the thickness of the nickel thin strip 2 in the middle is 0.08mm.

[0026] The nickel thin strip 2 is made of alloy nickel with a nickel content greater than 90%, and the aluminum thin strip is made of pure aluminum.

[0027] method embodiment

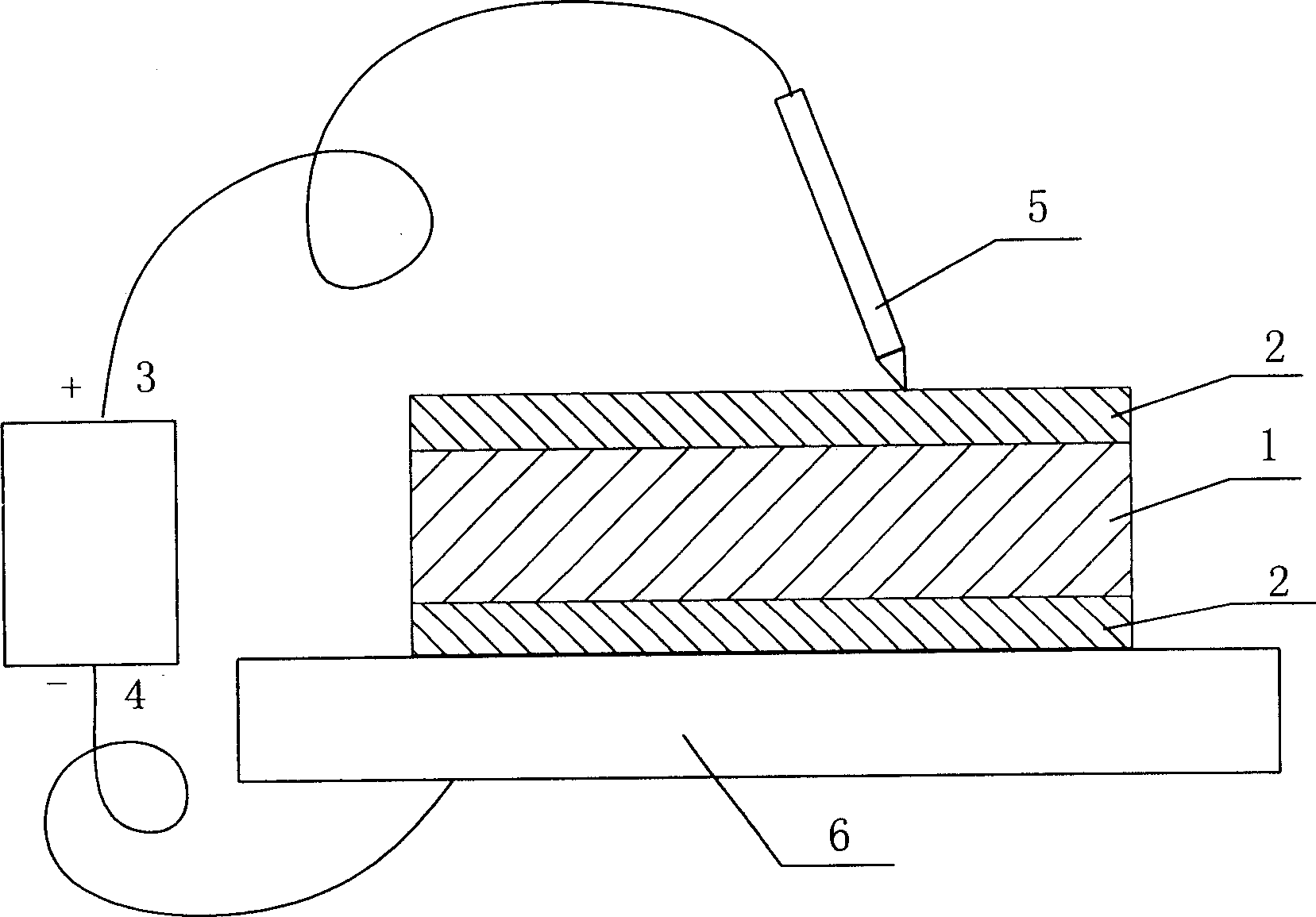

[0028] Such as image 3 , shows a kind of equipment and method for preparing the Al-Ni metal welding strip described in Example 1, the method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com