Vane speed regulator for electricity generation by wind power and ocean current

A technology of ocean current power generation and speed regulator, which is applied in the direction of wind turbine, wind motor combination, wind turbine control, etc. It can solve the problems of large speed regulation error, many wearing parts, complex structure, etc., and reach the range of stepless speed regulation Large, easy to repair, and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

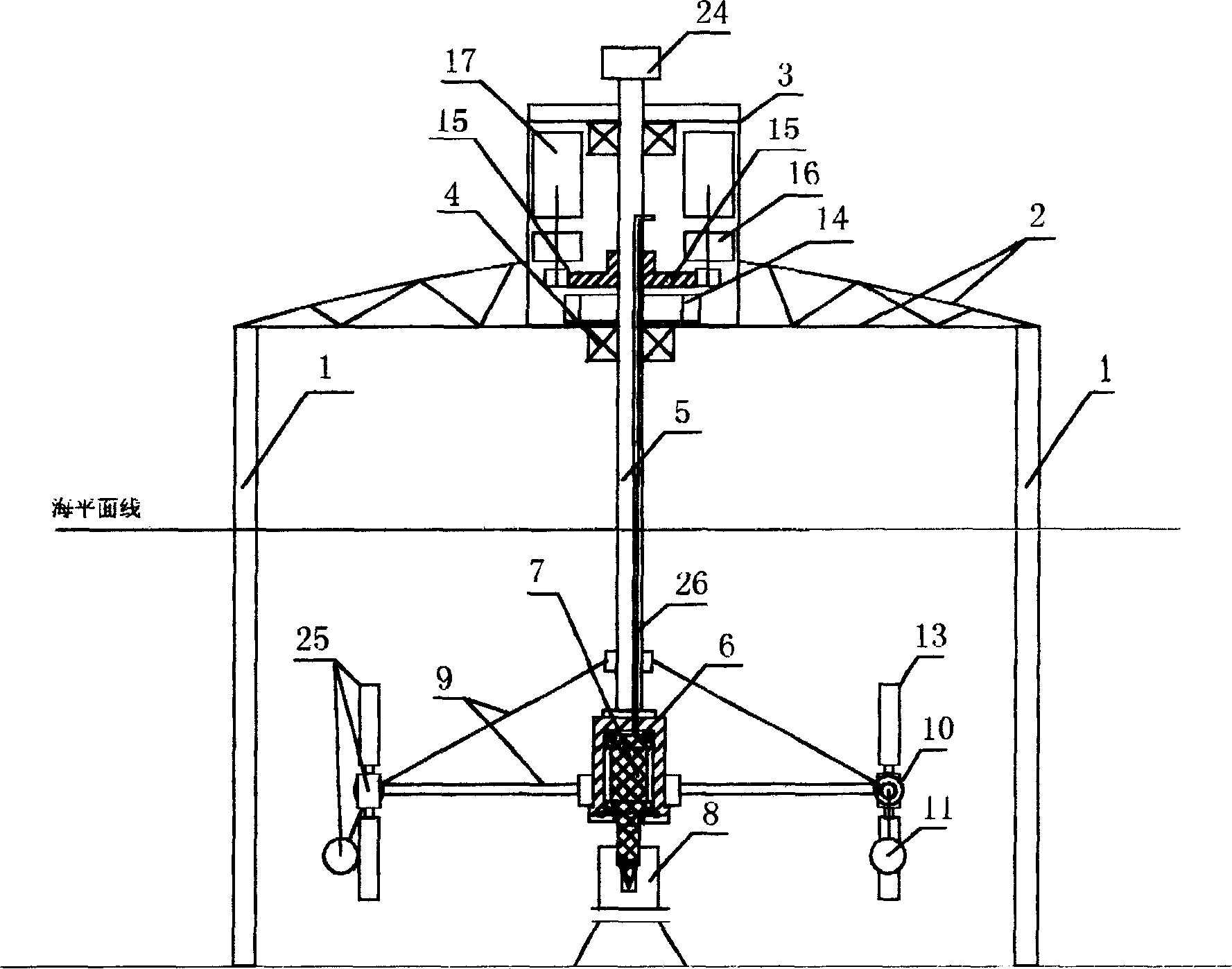

[0055] Shown in 4 / 8 page Fig. 2 is the structural diagram of the first embodiment of the triangular combined type, in accompanying drawing 2: tower base (1) connects drum (2) with slewing support structure or bearing (14) , the upper end of the drum (2) is provided with a blade shaft positioning (15), the upper end may also be provided with an upper fixed blade (16) and an upper bracket beam structure (17), and the lower end of the drum (2) is connected to the outside of the slewing bearing (8) The end is provided with a support beam (4), and the outer end of the support beam is connected to the speed regulating box (5), and the speed regulating box (5) is connected with the blade shaft (7) and the blade (3), and the speed regulating moving body (6) The running centrifugal gravity generates linkage to change the blade rotation angle to achieve high-precision speed regulation. The rotating cylinder (2) and the slewing support (8) are equipped with a transmission gear (9). The tr...

Embodiment 2

[0057] Shown in Fig. 3 on page 5 / 8 is the structural diagram of the second embodiment of the combined diameter type combined type, among which shown in accompanying drawing 3: the tower seat (6) is fixedly connected to the central fixed shaft (1), and is formed by a slewing support (9 ) or the bearing is movably connected to the rotating shaft (21), the upper and lower ends of the rotating shaft are provided with semicircular drag-reducing blades (2), and the outer end of the slewing bearing (9) is connected to the blades to form a fixed connection, and the middle end of the rotating shaft is connected with a support beam ( 8), the outer end of the support beam is provided with an automatic speed-regulating structure (22), including: the blade shaft (11), the connecting blade (10), and the centrifugal operation of the speed-regulating moving body (19) on the support beam, driving the transmission shaft (20) Upload the connecting piece, the transmission piece in the linkage spee...

Embodiment 3

[0059] Shown in Figure 4 on page 6 / 8 is the structure diagram of the third embodiment that can be opened or folded in the shape of an umbrella for ships. In Figure 4, the rotating shaft (1) is connected to the bearing (2), and the tower is connected (3), the rotating shaft is provided with a stay rope fixer (13), and the stay rope fixer (13) tightens the rope (12), and the umbrella shape structure is opened by the pulley (17) and the rope hook (11), and the lifting Crossbeam movable wheel (4), movable joint (5), connect support crossbeam (18), support crossbeam (18) outer end is provided with speed regulating box (6), the movable joint of blade shaft movable location (10) is opened, adjusts The speed box body (6) is equipped with a horizontal shaft upper transmission part that is movably connected to the actuator on the blade shaft (8). Blade (9) rotates blade angle, plays speed regulating effect, is provided with the braking structure (14) that shuts down on the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com