Double power composite current washing machine

A washing machine and dual power technology, applied in the field of household electrical appliances, can solve the problems of long time for washing clothes, poor washing uniformity, long time for washing clothes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

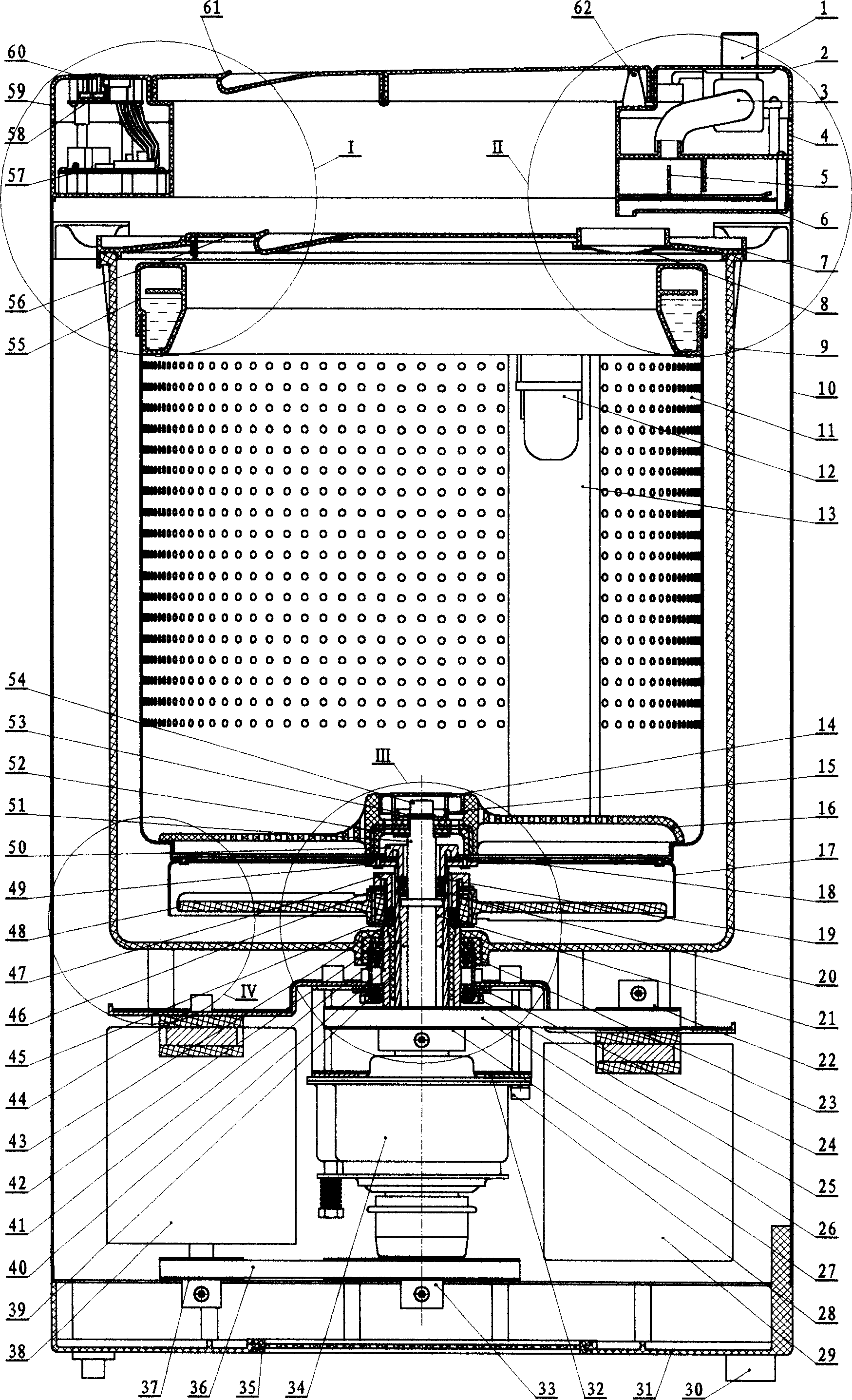

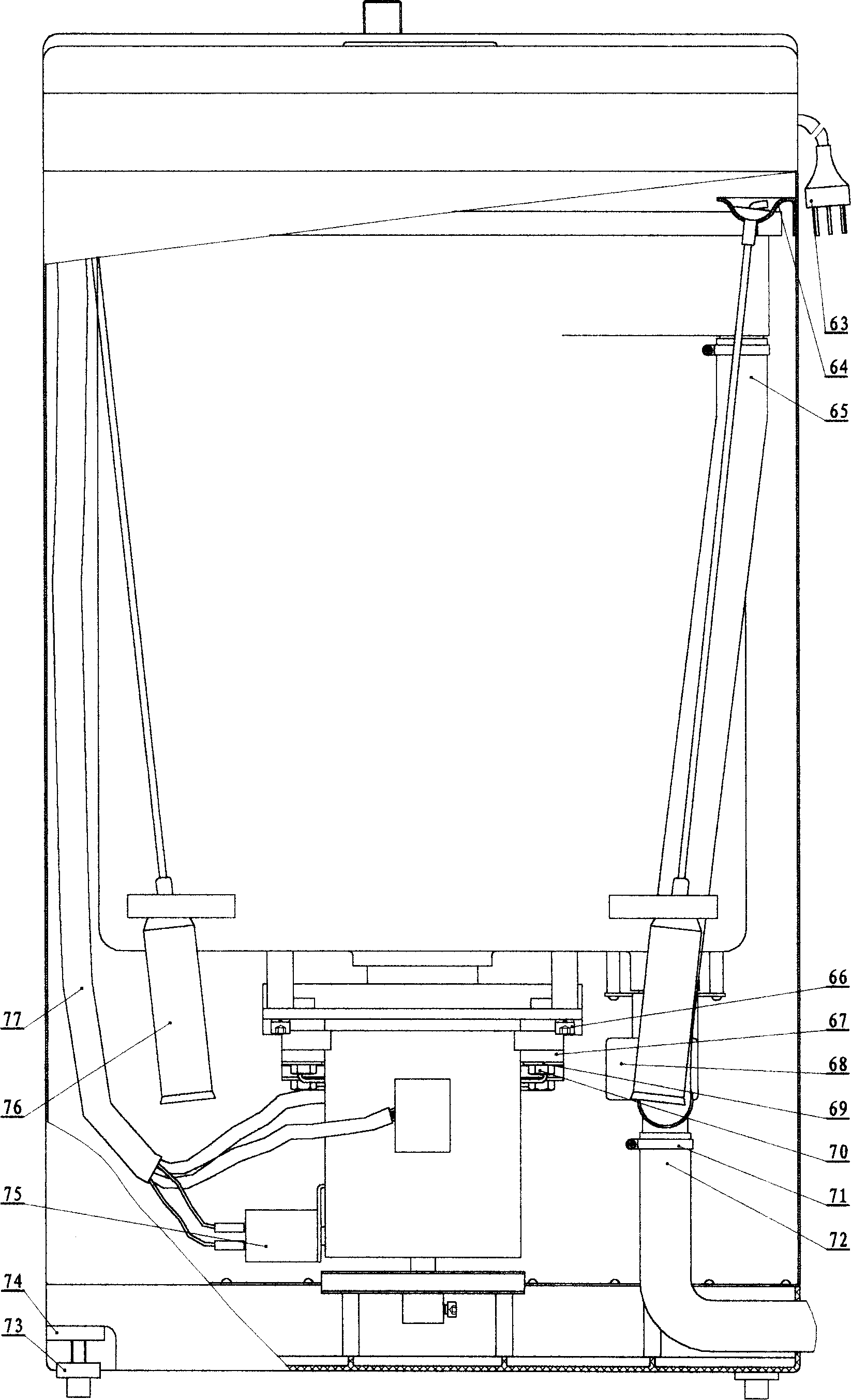

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] The impeller drive type structure of impeller 48 of the present invention and washing dehydration barrel 11 non-axial is as figure 1 Shown: upper corners 64 are installed on the upper four corners of the box assembly 10, and four suspender mounting holes are formed on the bottom of the water bucket 9, and the water bucket 9 is hung on the box assembly with four suspender assemblies 76 10 on the upper angle plate 64; the central support 44 is fixed on the bottom of the water tank 9 by screws; the middle part of the impeller shaft 40 is installed in the inner rings of the two bearings, and the outer rings of the two bearings are fixed on the upper end cover of the impeller shaft support 23 and the lower end cover 24 of the impeller shaft support, one end of the impeller shaft 40 passes through the round hole of the upper end cover 23 of the impeller shaft support and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com