Method of high speed high pressure spraying decoration on textile paste yarn dyeing production line and its device

A production method and technology of a production device, which are applied in the field of textile printing and dyeing, can solve the problems of difficult control of arrangement and combination, large energy waste, low production efficiency, etc., and achieve the effects of saving energy and raw materials, and high utilization rate of dyestuffs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

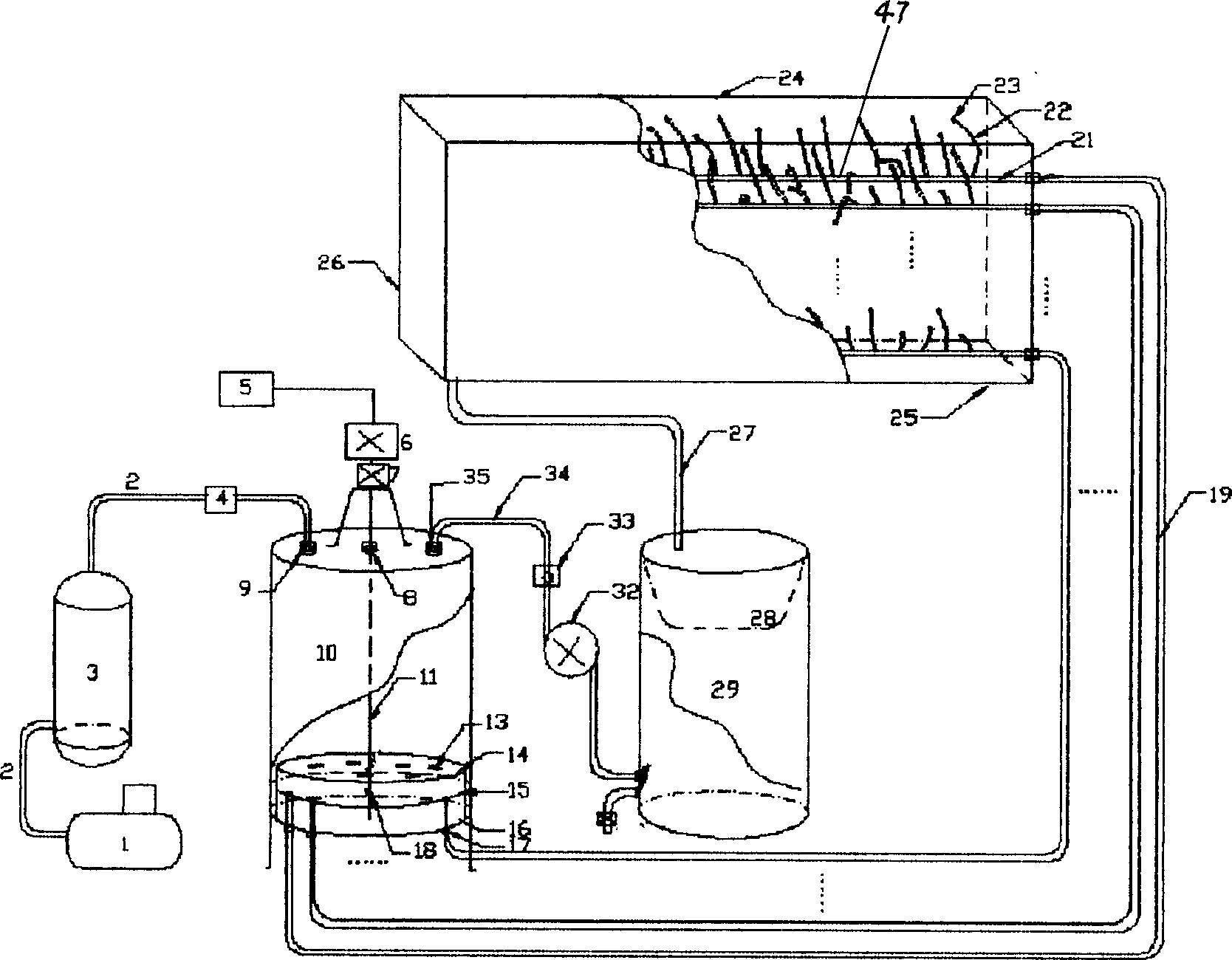

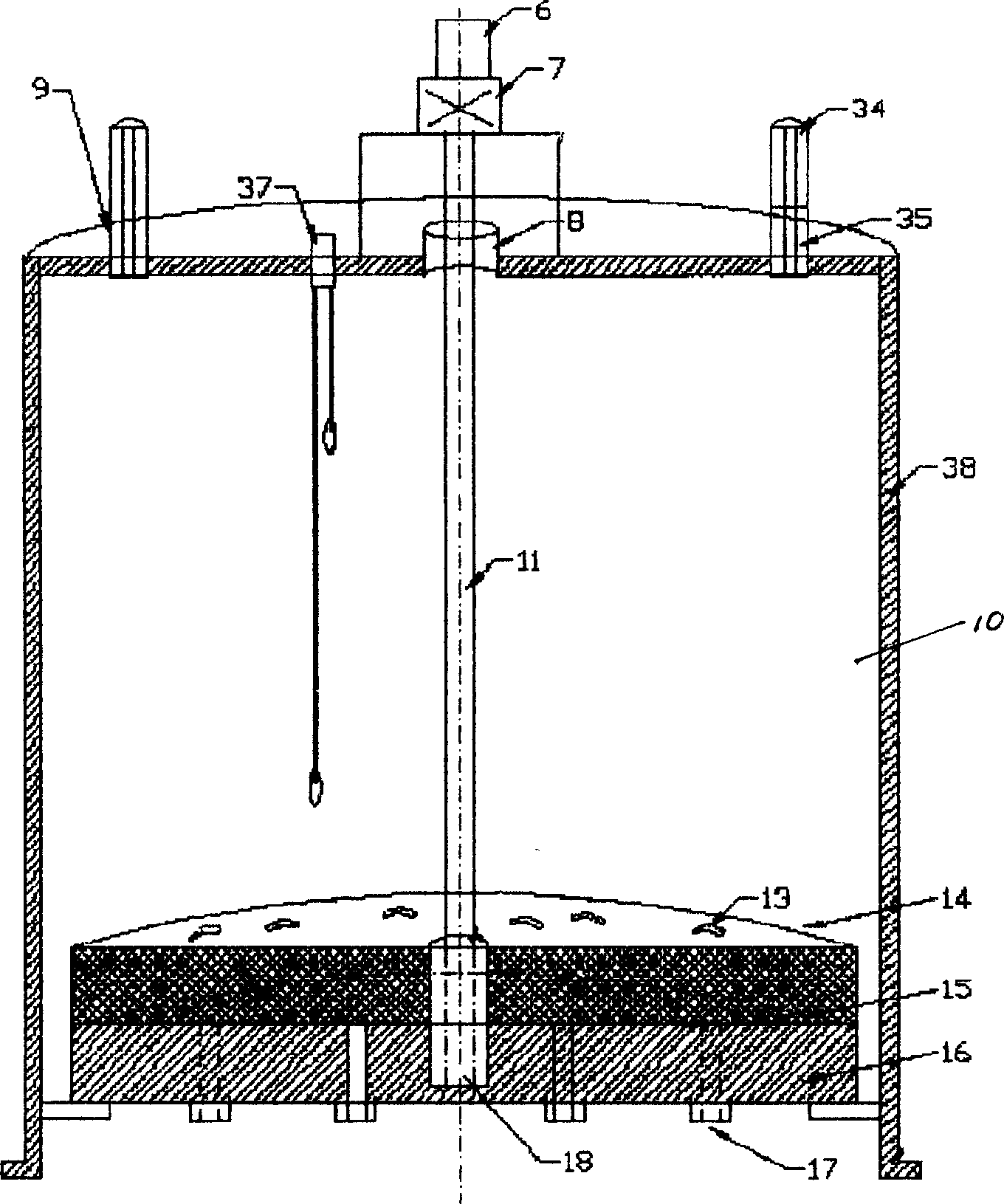

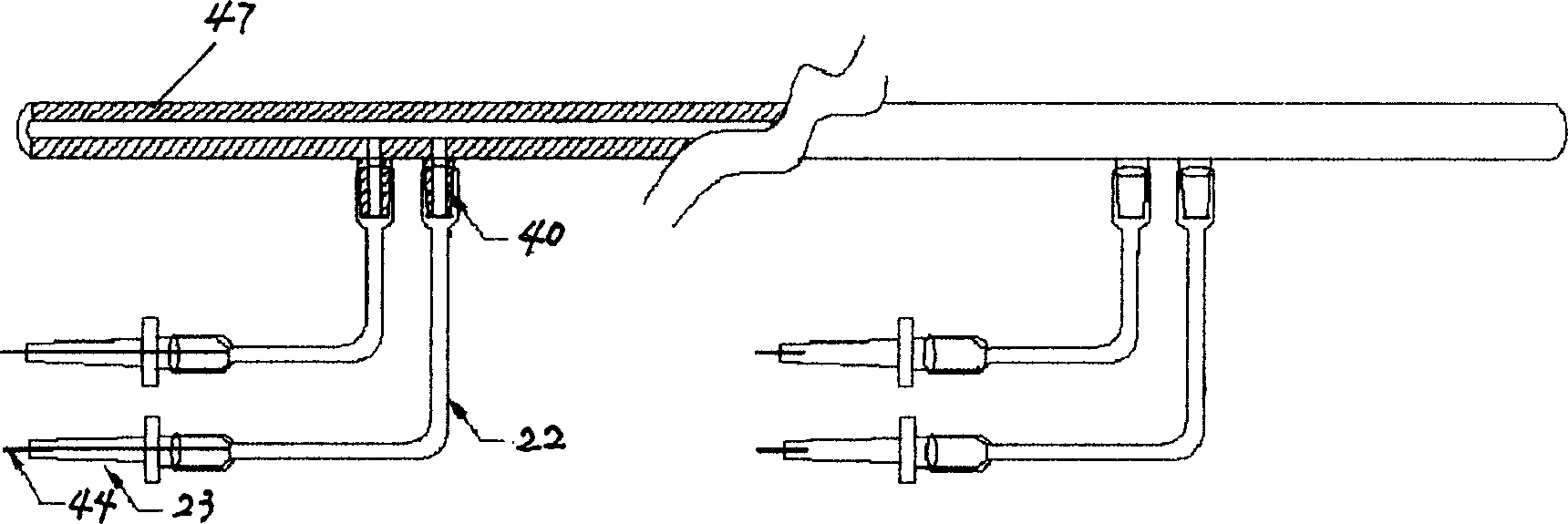

[0041] Embodiment 1: the production method and device of high-speed and high-pressure flower spraying on the textile sizing and dyeing production line of the present invention are to install distributor 21 and flower spraying panel between each dyeing vat on the existing textile dyeing yarn and sizing production line twenty three. Such as figure 1 The shown device of the present invention comprises a raw material storage filter tank 29, an injection control cylinder 10, an air storage tank 3, a distributor 21, a spray panel 24, a pinhole nozzle 23, a water pump 32, an air pump 1 and pipelines, etc. The raw material storage filter tank 29 of the device 28 is connected to the feed port 35 on the top of the injection control cylinder 10 through the water pump 32 and the feed pipe 34. A check valve 33 is installed on the feed pipe 34, and the injection control cylinder 10 is connected to the distribution valve through the feed pipe 19. The gas storage tank 3 communicates with the...

Embodiment 2

[0046] Embodiment 2: Add this device after the dryer before the sizing vat of the denim sizing and dyeing integrated machine, and spray the fading agent, so that the fabric woven from ordinary uniform yarn has the effect of slub yarn.

[0047] Discoloration agent: 20% aqueous solution of sodium hypochlorite 10 liters

[0048] Penetrant: 100ml

[0049] Divide pinhole nozzles 23 into 5 groups of 1520 in total, each group of pinhole nozzles 23 corresponds to a group of distributors 21, and each group of distributors 21 corresponds to a concentric circle on the discharge orifice plate 16 of the integrated valve. A group of discharge holes 15, each group of pinhole nozzles 23 are evenly distributed into the mesh holes 45 of the spray panel 24 according to the design requirements; the pinhole nozzles 23 are grouped with the distributor 21 through the thin hose 22 The distributor 21 communicates with the sealing joint 17 of the feeding pipe through the feeding pipe 19; the flower sp...

Embodiment 3

[0050] Embodiment 3: This device is added before the penultimate dyeing vat of the denim sizing and dyeing machine, and the fading agent is sprayed, so that the fabrics woven from ordinary cotton yarns with uniform thickness and thickness show slub patterns of different gray levels.

[0051] Fading agent: 10 liters of potassium permanganate solution with a concentration of 12% to 15%

[0052] Penetrant: 50g

[0053] The traveling speed of the yarn is set to 18m / min; the pinhole nozzles 23 are divided into 5 groups, a total of 760 are inserted into the mesh type small holes 45 of the spray panel 24 according to the law of uniform distribution, and the remaining processes are the same as in the second embodiment .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com