Logistics operation training system and making method

A training system and operation technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of unsuitable training, high price, and discomfort in the training scene, and achieve the function of increasing isolation protection, improving the performance of processing technology, and reducing friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

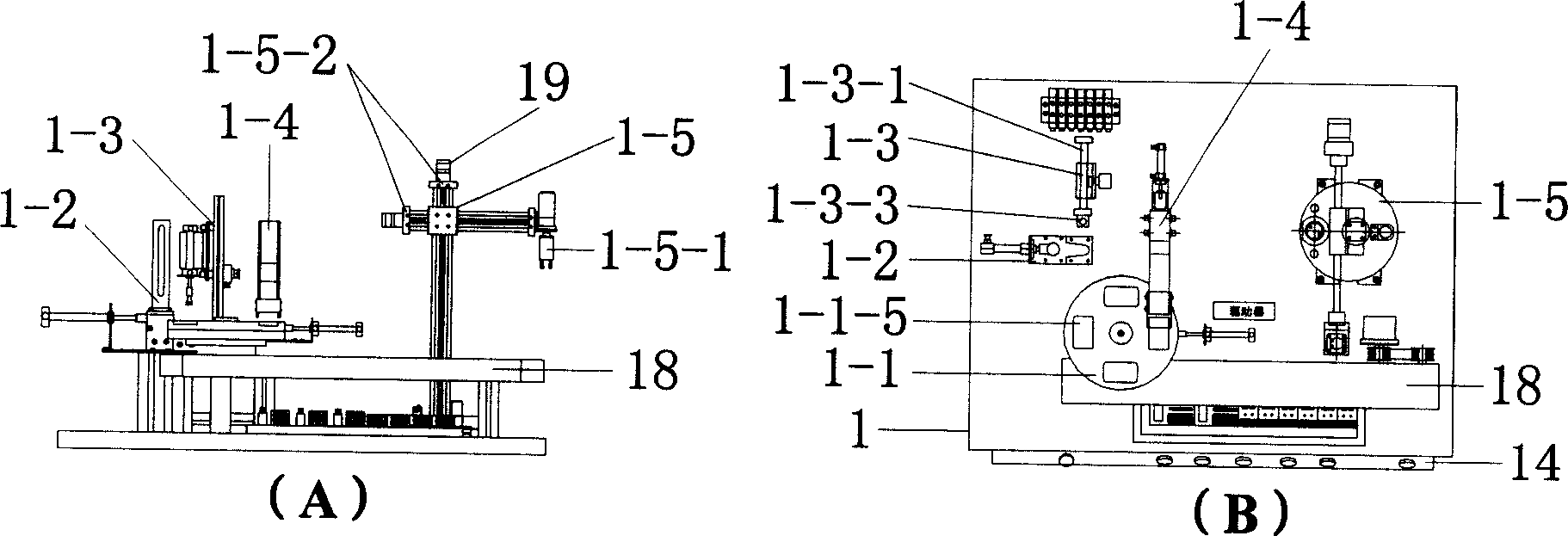

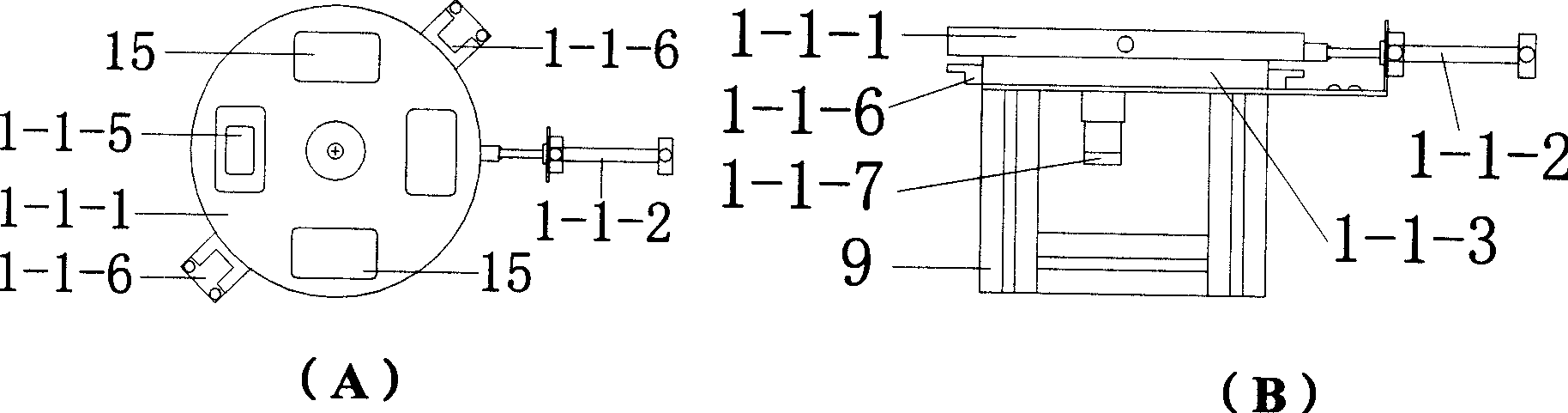

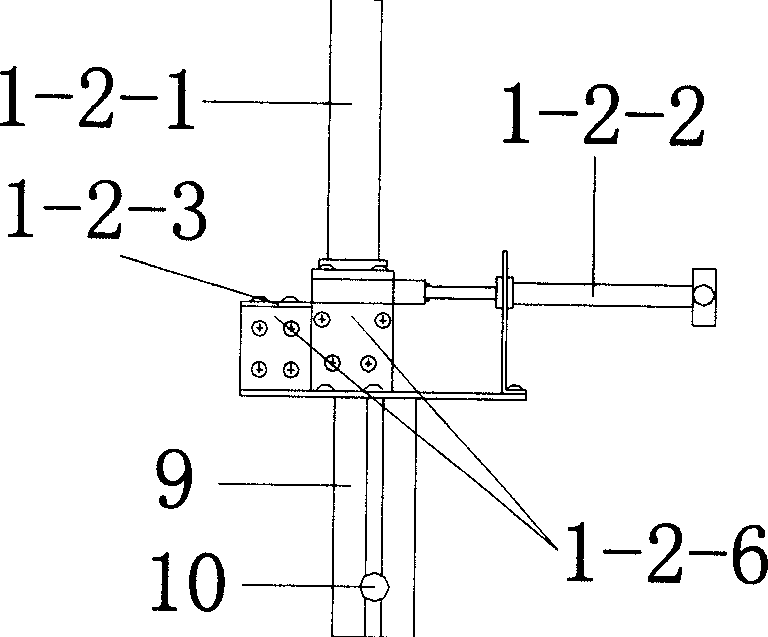

[0115] The manipulator assembly and handling unit (1) is equipped with a cargo shifting turntable mechanism (1-1), a cargo pushing mechanism (1-2), a cargo translation mechanism (1-3), and a cargo box pushing mechanism (1-4) , a four-axis linkage manipulator mechanism (1-5) and a transmission mechanism (18).

[0116] Along one side of the manipulator assembly and handling operation unit (1), a transmission mechanism (18) is relatively fixed and fixed, and one side of one end of the transmission mechanism (18) is provided with a cargo shifting turntable mechanism (1-1), and the cargo shifting turntable mechanism The lower part of (1-1) is provided with a substrate support (9), the lower end of the substrate support (9) is fixedly arranged on the manipulator assembly and handling operation unit (1), and the top of the substrate support (9) is provided with a turntable base (1-1 -3), the two sides of the turntable base (1-1-3) are oppositely provided with positioning sensors (1-1...

Embodiment 2

[0122] The cargo automatic identification buffer operation unit (2) is provided with an incoming delivery mechanism (18), several sorting buffers (2-2) and an outgoing delivery mechanism (18), and the lower part of the incoming delivery mechanism (18) is fixedly set The base bracket (9), the lower end of the base bracket (9) is relatively horizontally fixed on the automatic cargo identification buffer operation unit (2) along one side of the automatic cargo identification buffer operation unit (2), and the delivery mechanism for incoming goods (18 ), the lower part of the base bracket (9) is fixedly arranged on the lower part of the base bracket (9), and the lower end of the base bracket (9) is fixedly arranged on the cargo automatic identification buffer operation unit (2), and the upper end of the base bracket (9) is relatively parallel and fixedly arranged with parallel belts (1- 6-1), one end of the parallel belt (1-6-1) is provided with a tension regulator (1-6-4), and the...

Embodiment 3

[0126] The stacking operation unit (3) is provided with a supply pallet mechanism (3-1), a pallet transmission mechanism (18), a cargo lifting mechanism (3-3), a cargo pushing mechanism (3-4) and a cargo transmission mechanism (18) , the main body of the tray supply mechanism (3-1) is a substrate support (9), the substrate support (9) is fixedly arranged on the stacking operation unit (3), and the both sides of the substrate support (9) are fixedly provided with a tray cylinder (3 -1-6), a parallel belt roller support mechanism (3-1-3) is set along the base support (9), and the parallel belt roller support mechanism (3-1-3) is connected with the double-row transmission parallel belt (3-1- 4) connected with each other, the two ends of the well-type tray storage mechanism (3-1-5) are connected with the double-row conveying parallel belts (3-1-4), and the lower side of the base support (9) is fixedly equipped with a DC motor (16), DC motor (16) drives double-row conveying paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com