Shaft drive buffer mechanism

A buffer mechanism and shaft transmission technology, which is applied in the direction of couplings, mechanical equipment, elastic couplings, etc., can solve the problems of inconvenient installation and increased difficulty of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

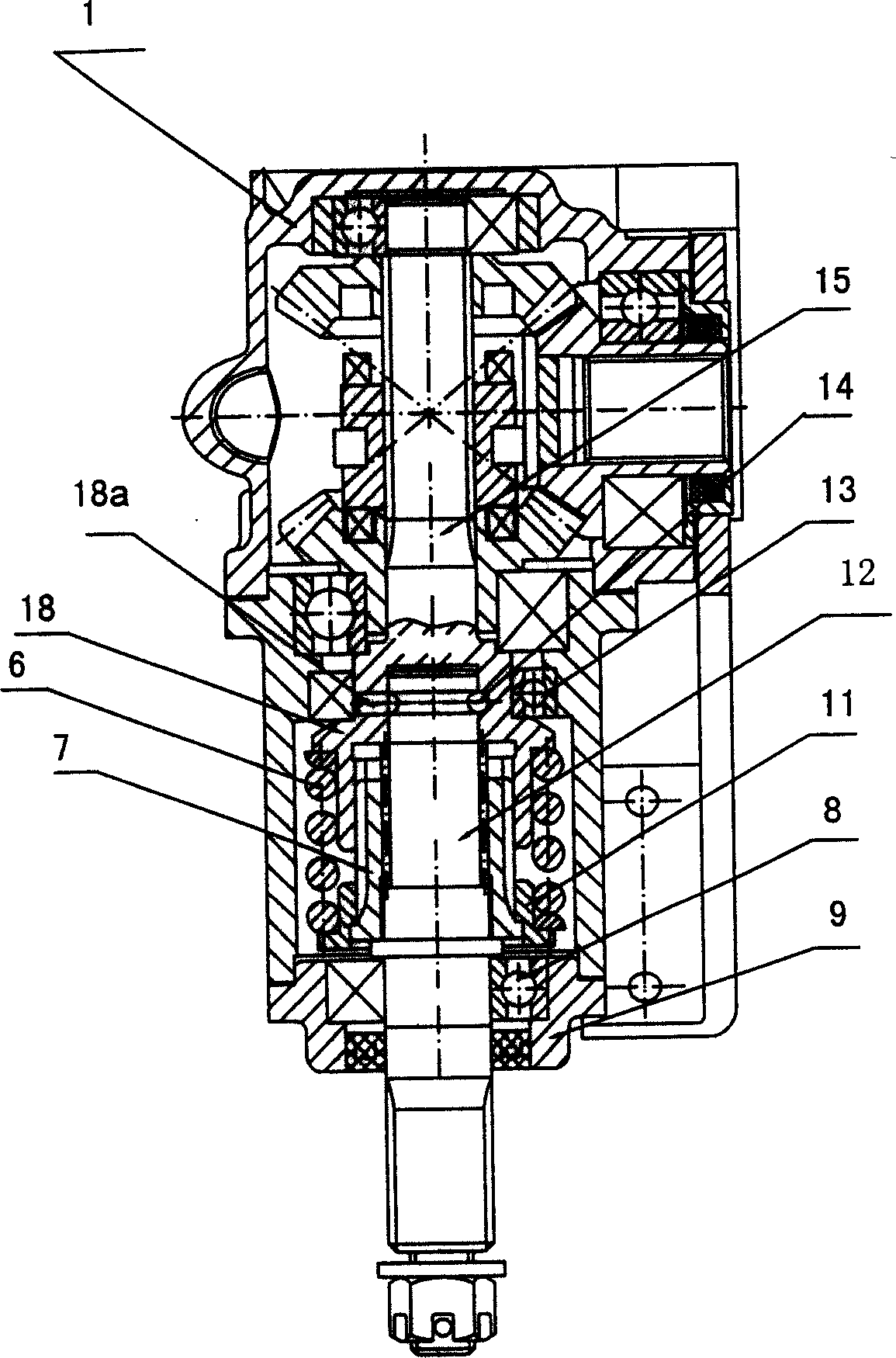

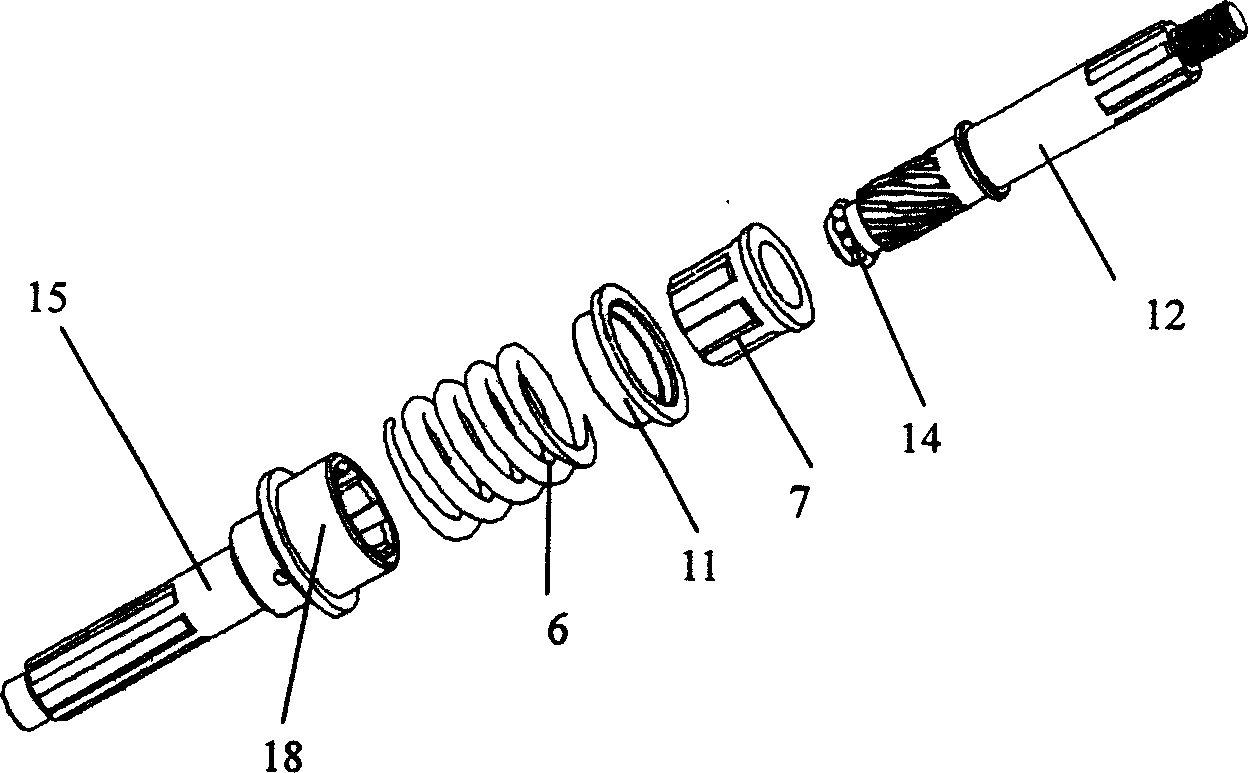

[0016] Referring to the above-mentioned drawings, a shaft transmission buffer mechanism is characterized in that: the power input shaft of the shaft transmission and the power output shaft 12 are splined through the spline sleeve 7 with the compression spring 6 outside, and the power output shaft 12 is splined. The front end is provided with an outer R groove, which matches the inner R groove of the power input shaft, and steel balls 14 are arranged in the inner and outer R grooves.

[0017] The above-mentioned power input shaft is a shaft sleeve 18, and the shaft sleeve 18 is connected with the outer garden of the spline sleeve 7 by a straight tooth spline, and the inner hole of the spline sleeve 7 and the power output shaft 12 are a helical tooth spline Connection; the above-mentioned shaft sleeve 18 has a steel ball installation hole 18a communicating with the inner R groove.

[0018] The present invention is specifically applied in the three-wheel motorcycle engine shaft t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com