Embedded combined bedstead

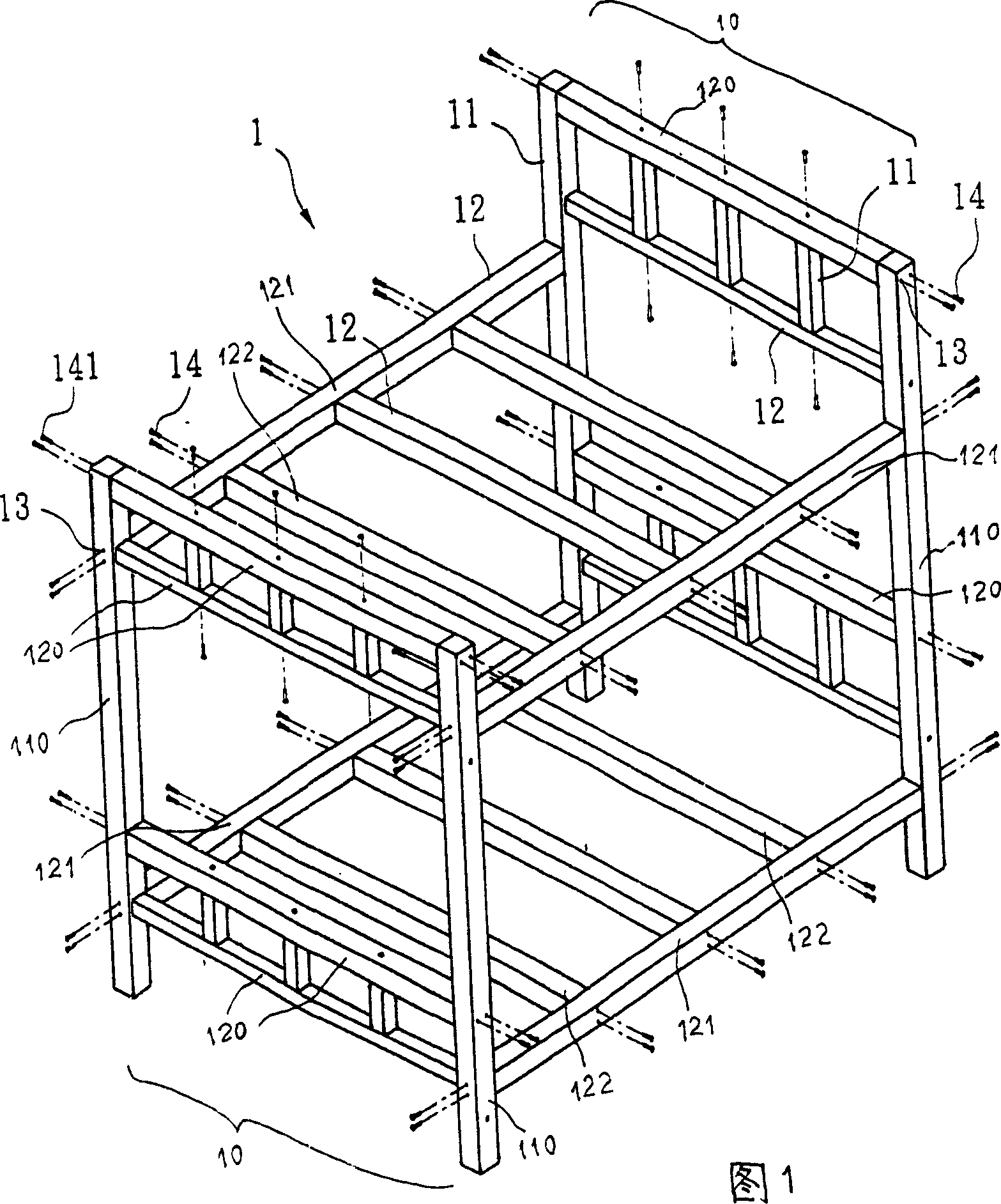

A technology of embedded cards and bed frames, which is applied to bed frames, other seating furniture, household appliances, etc., can solve the problems of shaking combined bed frame 1, low texture of combined bed frame 1, and influence on structural strength, etc., to achieve Assembly and disassembly save time and effort, the structure is not easy to be damaged, and the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

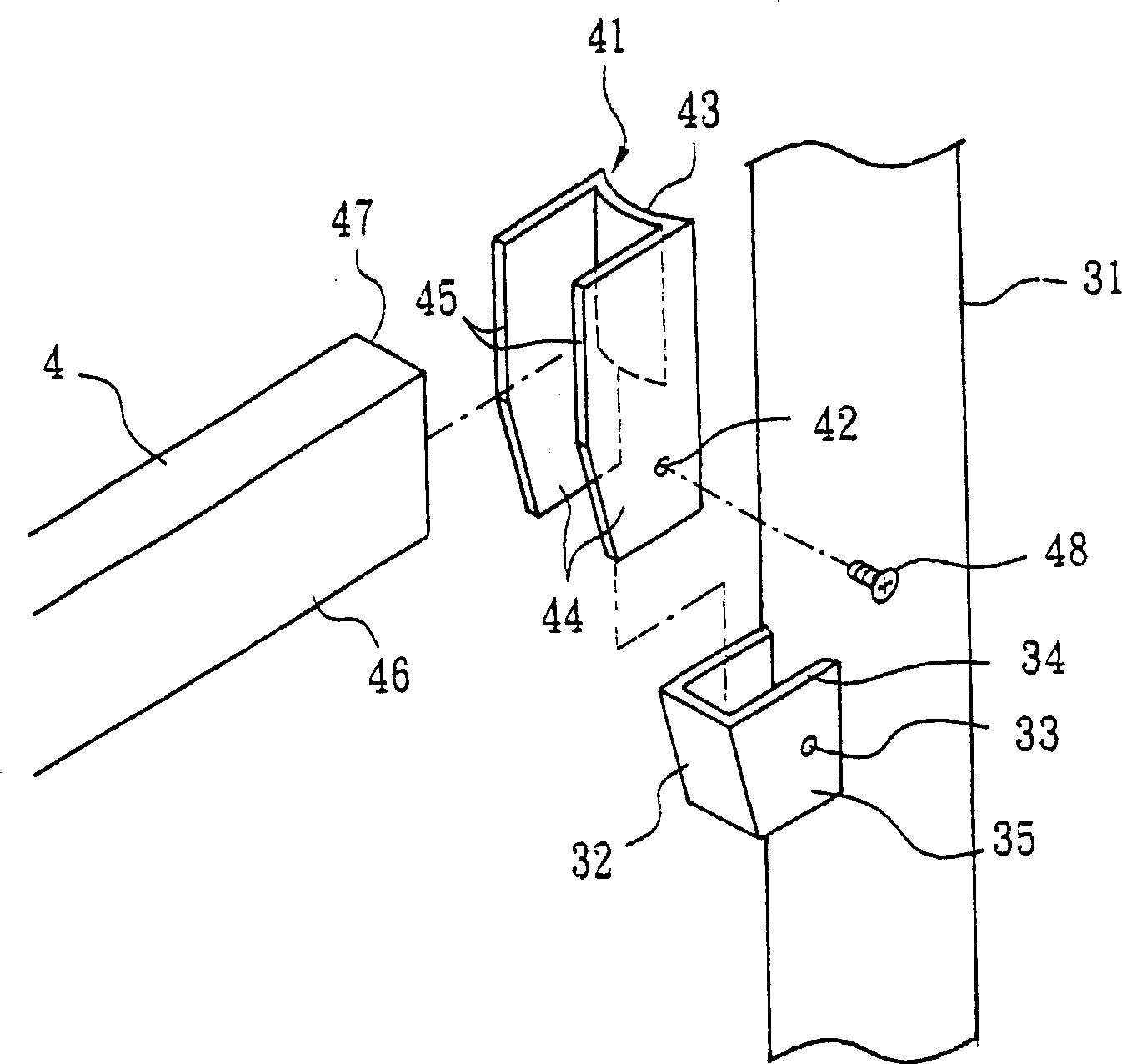

[0033] For the structure of a preferred embodiment of the embedded card type combined bed frame of the present invention, please refer to figure 2 . The embedded card type combined bed frame 2 includes two headboard groups 3, four main pipes 4 connecting the two headboard groups 3, multiple branch pipes 5 connected between the corresponding two main pipes 4, and multiple An insert 6, a pair of stair sets 7 connected to the upper and lower corresponding two main pipes 4, and two connecting units 8 for connecting the branch pipes of the upper and lower two groups of mattress support surfaces.

[0034] See image 3 and review figure 2, each bedside frame group 3 includes two support standpipes 31 and four horizontal tubes 30, and each horizontal tube 30 is respectively connected between the two support standpipes 31 to form the frame-type planar structure of the bedside frame group 3 . The opposite side walls of the two supporting standpipes 31 of the two bedside frame groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com