Method and apparatus for rolling a tube

A technology of rolling direction and equipment, applied in the direction of metal rolling, metal rolling, metal rolling stand, etc., can solve the problem of high rolling power of side rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

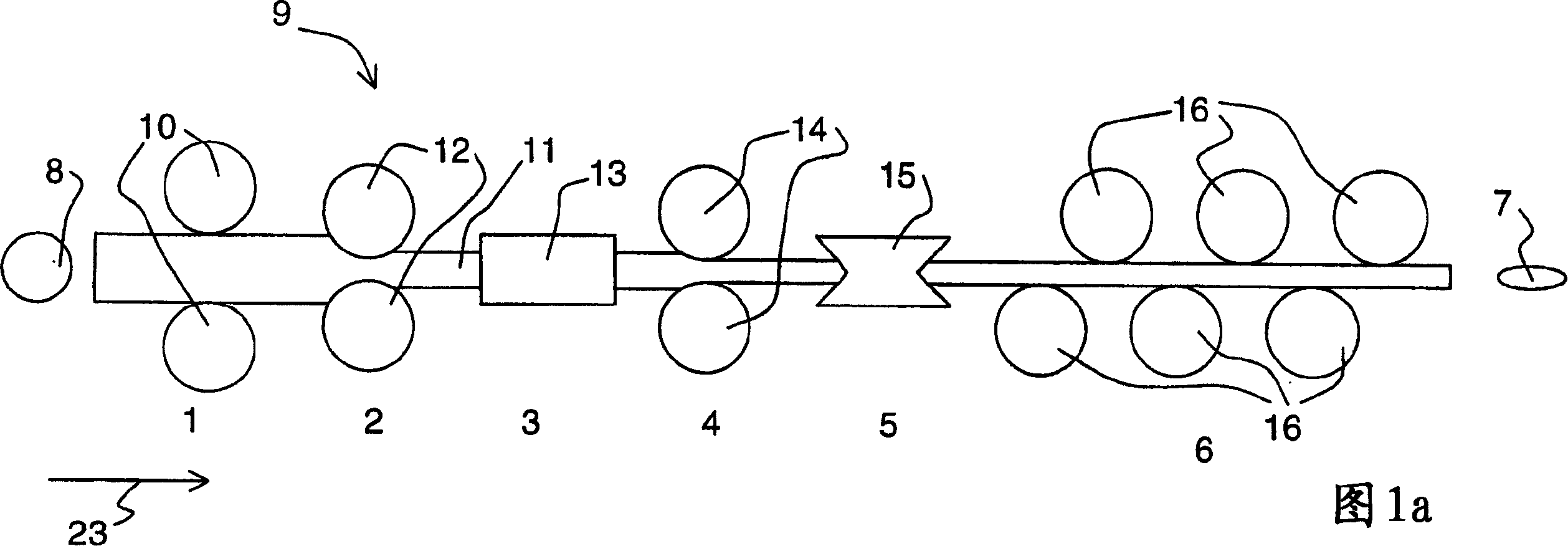

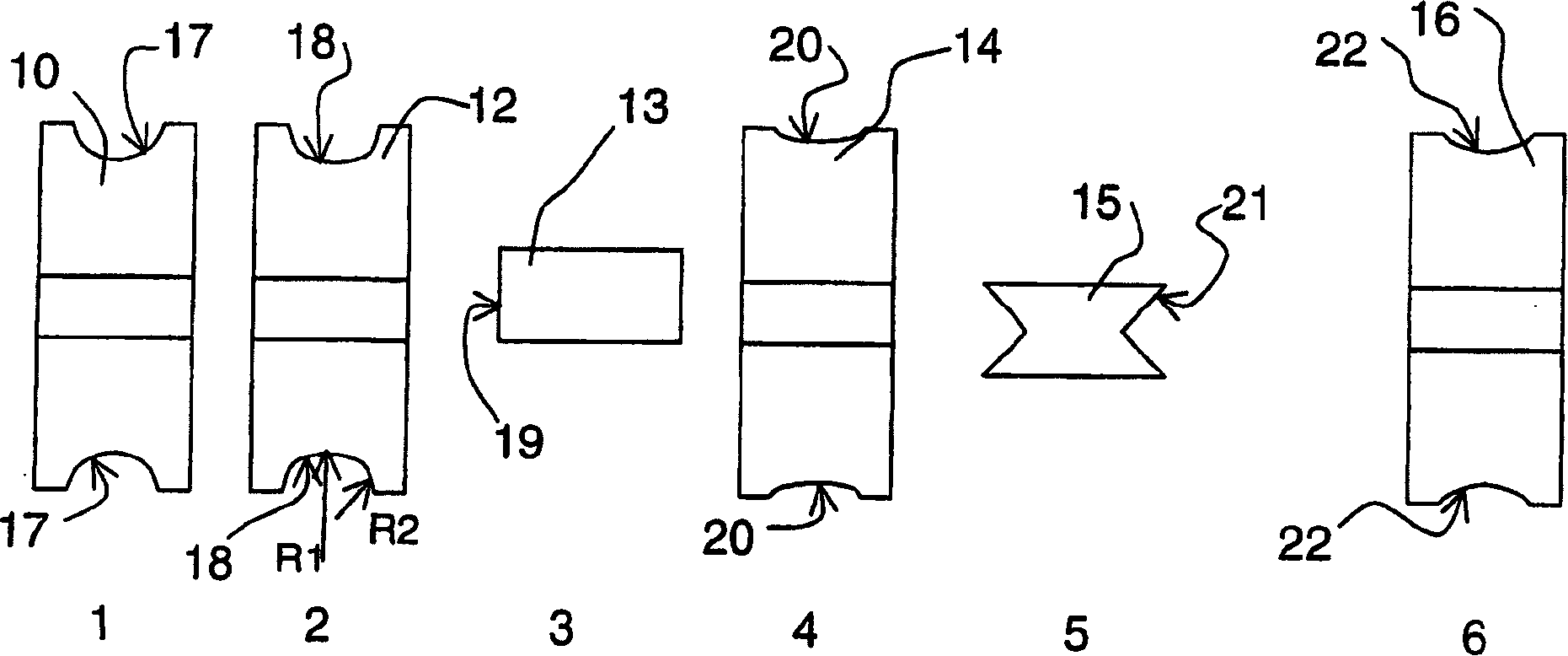

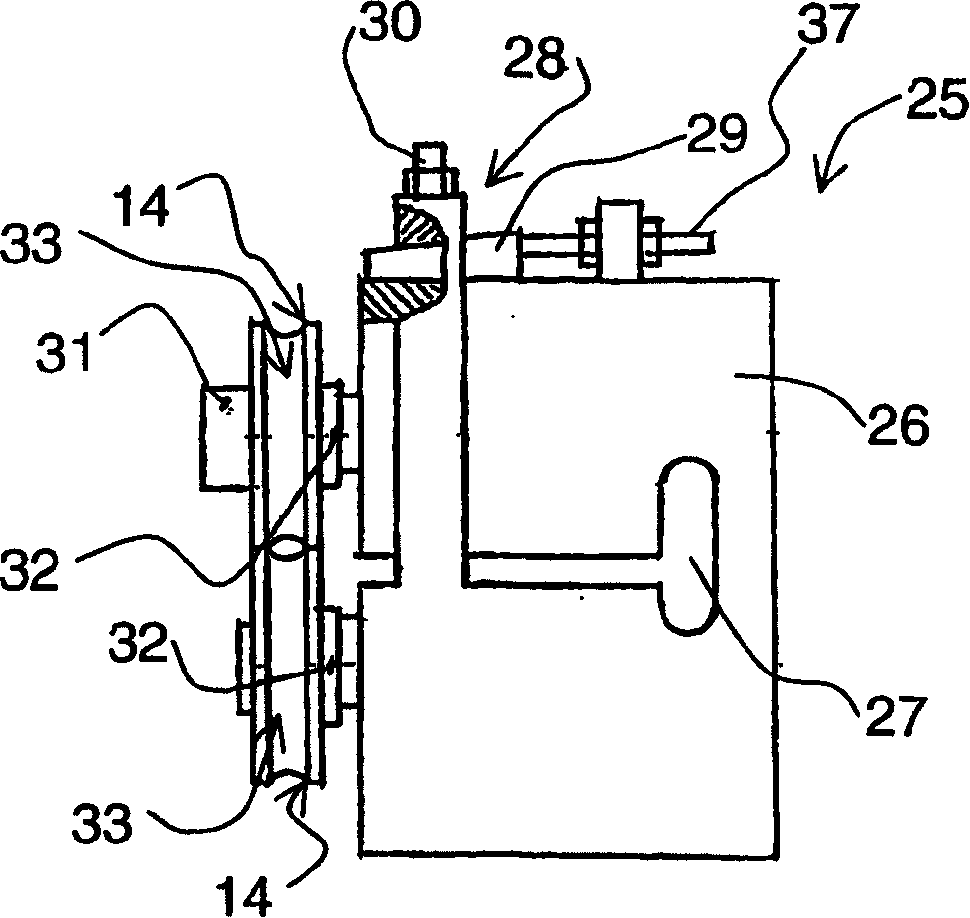

[0012] Figures 1a and 1b show the apparatus of the present invention for the manufacture of oval tubes. Figure 1b A cross-section of the roller shown in FIG. 1 a seen in the direction of arrow 23 is shown. The cross section of the metal pipe is circular and made of hard or soft metal, such as copper pipe, the metal pipe enters the rolling equipment 9 in the conveying step 1, and the two conveying rollers 10 whose shape is consistent with the metal pipe 11 transfer the metal The tube is kept on a given straight line for the rolling operation. The conveying rollers can be positioned above and below the metal pipe, or on both sides thereof, and the surface 17 of the conveying roller in contact with the metal pipe has the same shape as the metal pipe. Conveyor rolls 10 convey the metal tube 11 to the roughing roll 2, where two roughing rolls 12 flatten the round metal tube, thereby changing the final dimensions of the tube. The roughing rolls 12 are positioned above and below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com