Z-shaped small-sized cement concrete hollow filled non-clod bridge thermal insulation building block and its making method

A technology for thermal insulation blocks and blocks, which is applied to building components, walls, buildings, etc., can solve problems such as the inability to fundamentally solve the problem of thermal (cold) bridges and poor thermal insulation performance of blocks, and achieve the overall connectivity of masonry. Good, good thermal insulation performance, strong anti-collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

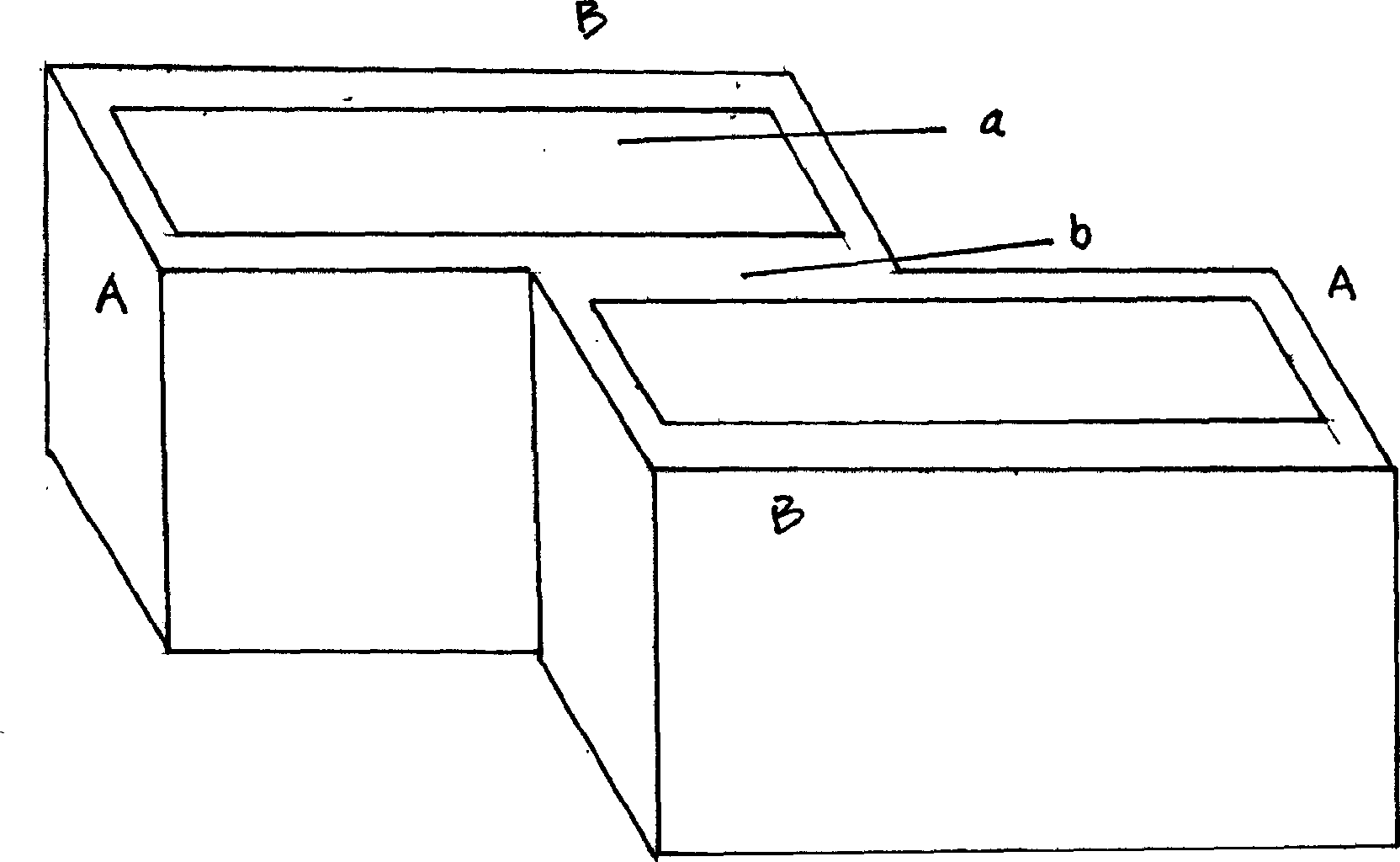

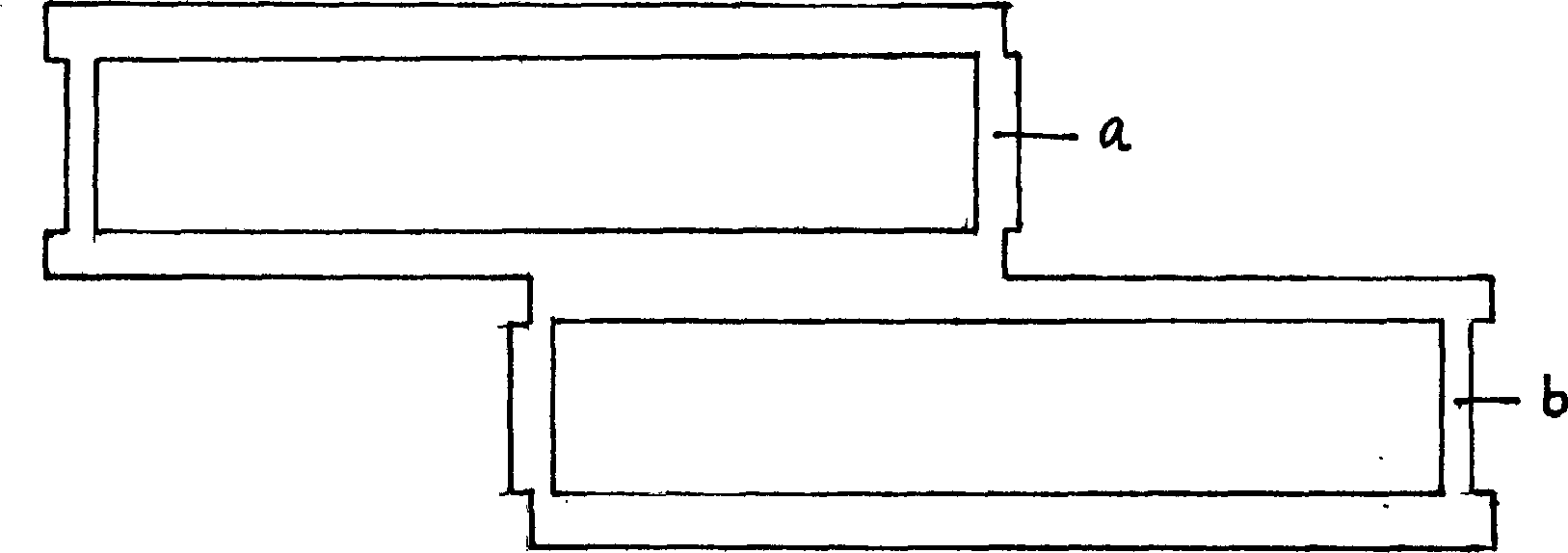

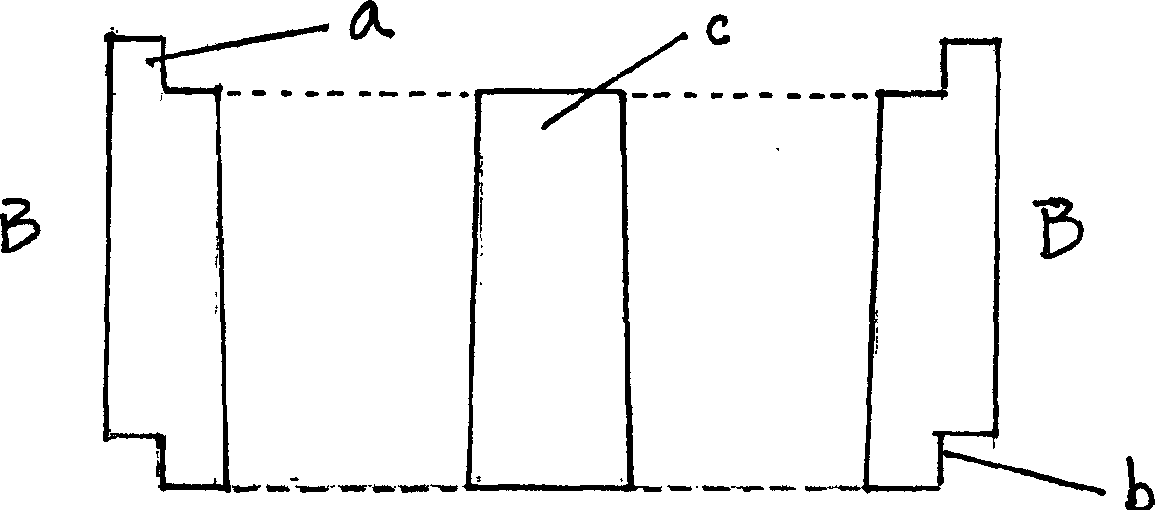

[0027] 1. Press figure 1 Make molds, and produce Z-shaped blocks on the block forming machine with the production method of ordinary cement concrete hollow blocks, so that the length of one side of the block is 400mm, the length of the overlapping part is 200mm, the width of one side is 120mm, the overlapping part is 240mm, and the height is 200mm. The top surface of the block is grooved convex strips, and the grooves and convex strips can be inlaid. The upper edge of the block strip is convex, and the lower edge is concave. When laying masonry, the lower edge is the grouting surface, and the upper edge is the grouting surface. See Figure 7 , image 3 . Production auxiliary supporting blocks, as shown in Figure 4, 3 / 4 block, Figure 5, 2 / 4 block, Image 6 , 1 / 4 block.

[0028] The main block and auxiliary block can be combined to form multiples of 400mm and remainders of 100, 200, and 300mm to match the building modulus.

[0029] After the block is formed, water and mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com