Thin layer welding repair technology for forging die cavity

A mold and cavity technology, which is applied in the field of forging mold repair technology, can solve the problems of long time-consuming, less repair times, high cost, etc., and achieve the effects of avoiding undercutting, reducing production costs, and eliminating internal stress in the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

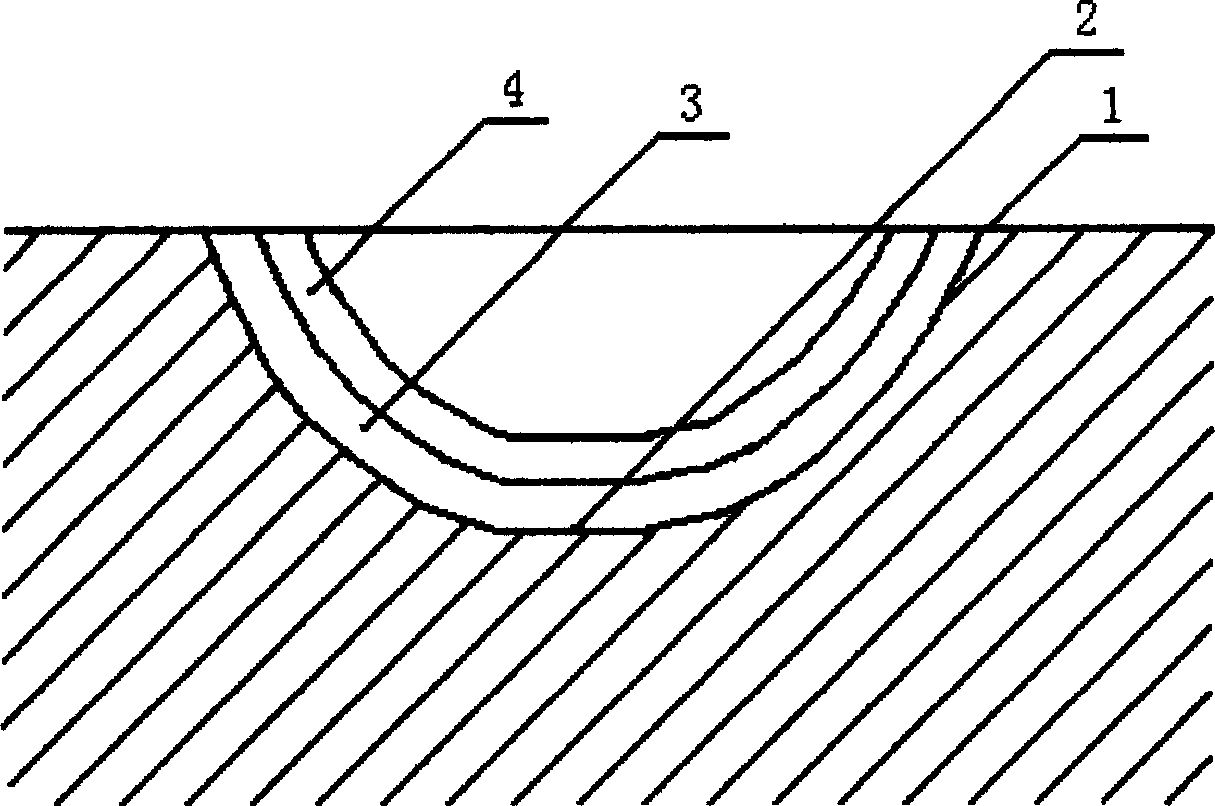

[0008] refer to figure 1 As shown, first expand the mold cavity evenly by 3-5mm, generally using a milling machine, then heat the mold as a whole to 350-400°C and maintain this temperature for welding repair, heat the welding rod to 300-350°C and keep it at 40-70 Minutes, it is used for welding repair after it is naturally lowered to normal temperature. During electric welding, start from the peripheral edge 1 of the mold cavity, weld the entire circumference of edge 1, and then gradually carry out welding repairs to the middle of the mold cavity 2 based on this circumference , and finally ends in the middle 2, its welding repair track is similar to concentric circles, and adopts multi-layer welding, such as figure 1 The first layer 3 is welded first, and then the second layer 4 is welded, and so on. The thickness of each layer of welding repair is controlled between 0.8-1.5mm, and each layer starts from the edge 1 and ends at the middle of the mold cavity 2 , until it slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com