Motor reduction gear box

A reduction gear box, gear box technology, applied in the direction of vehicle gearbox, gear transmission, belt/chain/gear, etc., can solve the problems of high manufacturing cost, high material consumption, poor motor sealing, etc., to achieve convenient manufacturing and assembly , The effect of good sealing performance of the whole machine and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

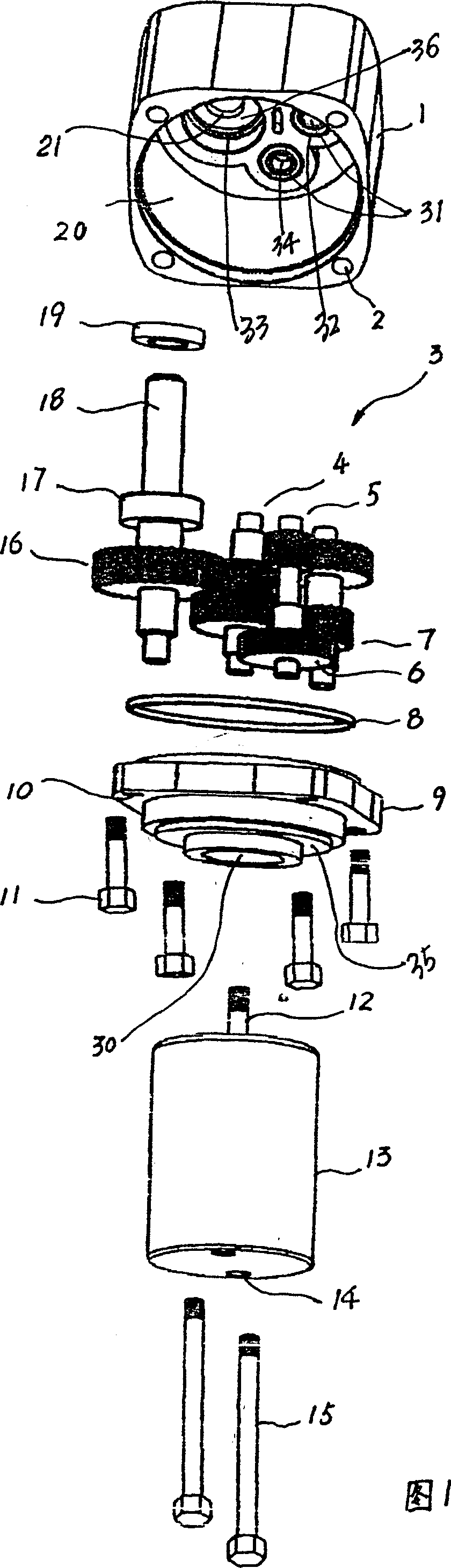

[0019] Embodiment: A motor reduction gear box, which includes a motor 13 , a gear box body 1 , an end cover 9 and a gear reduction mechanism 3 . The gear reduction mechanism 3 is a four-stage gear reduction mechanism, which is arranged in the sealed cavity between the reduction box body 1 and the end cover 9. A groove 37 is arranged on the inner side of the end cover, and Four accommodating holes 38 are provided on the bottom surface, and corresponding accommodating holes 31 are provided on the box body 1 . The four-stage gear reduction mechanism 3 is a standard structure, and each stage of transmission components is composed of a transmission shaft, an input gear and an output gear. The input gear of the second stage is meshed, and the upper and lower ends of the transmission shaft are fixed in the housing holes 31 and 38 on the box body 1 and the end cover 9 through bearings. The input gear 6 of its first transmission part meshes with the motor drive shaft 12 .

[0020] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com