Method for cleaning a water electrolyzer

A water electrolyzer and electrolyte technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of lye waste, increased impurity content, environmental pollution, etc., to reduce alkali consumption, reduce consumption, and improve the sealing performance of the tank body Effect

Inactive Publication Date: 2005-11-23

LUOYANG GLASS

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the cleaning process of the water electrolyzer in the domestic float glass production line is as follows: drain the electrolyte from the water electrolyzer, pass it into tap water for cleaning, mix the tap water with the potassium hydroxide solution remaining in the tank, and the calcium ion content in the tap water is 450mg / l, the magnesium ion content is 110.7mg / l; the iron ion content is 0.04mg / l; the hydrogen ion content is 5mg / l; the resistivity is 730-810μΩ. Liquor is directly mixed and discharged, which not only pollutes the environment, but also causes a lot of waste of lye

Method used

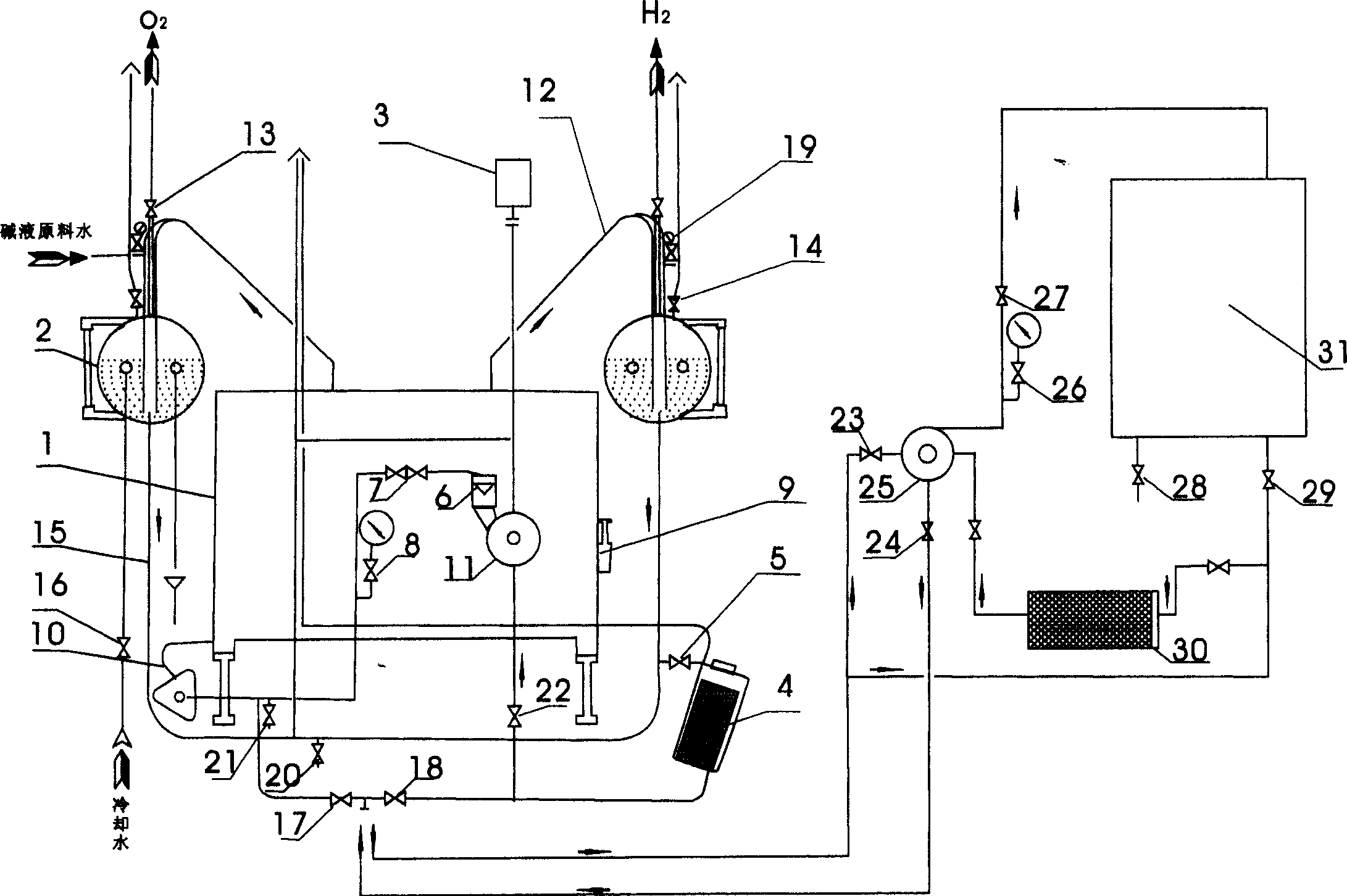

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0008] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0009] The concrete process of the inventive method is:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a cleaning method of water electrolysis cell. The procedure is: 1) The electrolyte in the small electrolysis compartment, i.e. the mixed solution of double distillation water and potassium hydroxide, is drained back to alkali box, and then the small electrolysis compartment is cleaned with double distillation water by means of circulating double distillation water between the small electrolysis compartment and a spare alkali box. Circulating is repeated over 2 times to fully mix double distillation water and the residual potassium hydroxide in the small electrolysis compartment. 2) The mixed solution is pumped back to alkali box, and laid aside for a certain time to form precipitation. A certain amount of potassium hydroxide solution is prepared so much so that the concentration conforms to the specified proportion of double distillation water to potassium hydroxide for restarting electrolysis. 3) The small electrolysis compartment is thoroughly cleaned with tap water and the washed water is directly discharged. 4) The small electrolysis compartment is washed with double distillation water and the washed water is directly discharged. The main point of the present invention is using double distillation water to clean electrolysis cell, which decreases potassium hydroxide consumption and production cost, and makes pollution-free discharge of washed water so that the defect of the existing cleaning methods would be overcome.

Description

Technical field [0001] The invention belongs to the treatment technology of water electrolyzer, and mainly relates to a cleaning method of water electrolyzer. Background technique [0002] The water electrolyzer is the main equipment for hydrogen production, and hydrogen is produced by electrolysis of double distilled water. The mixed solution of double distilled water and potassium hydroxide solution forms the electrolyte solution, wherein the double distilled water is distilled water obtained by secondary distillation, and the purpose of adding potassium hydroxide solution is to increase the conductivity during electrolysis. The electrolyte enters the water electrolysis cell to produce hydrogen by electrolysis; the principle of action is that when the electrolysis chamber of the water electrolysis cell is fed with direct current, the water in the electrolysis chamber is electrolyzed, hydrogen gas is precipitated at the cathode, and oxygen is precipitated at the anode. Doub...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25B15/00

Inventor 蔡晓玲赵宗洛许宁李学红吕国庆

Owner LUOYANG GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com