A new type of integrated water-cooled intake and exhaust device

An integrated, intake and exhaust technology, which is applied in the direction of exhaust devices, noise reduction devices, fuel heat treatment devices, etc., can solve the problem of air intake and exhaust not meeting explosion-proof requirements, emission deterioration, intake or exhaust leakage, etc. problem, achieve the effect of reducing temperature, improving utilization and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

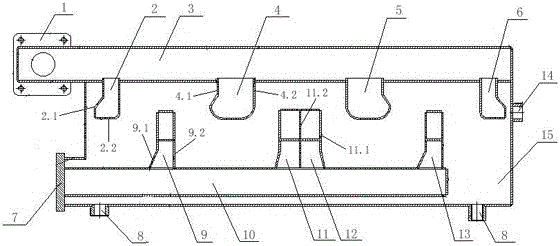

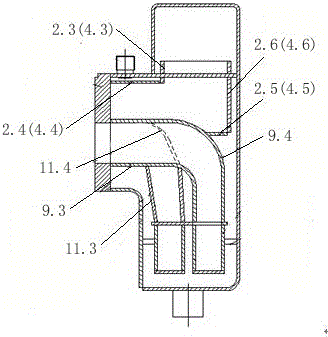

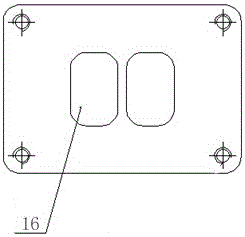

[0020] Such as figure 1 As shown, a new type of integrated water-cooled intake and exhaust device includes an intake channel 3, an exhaust pulse channel 10 and a cooling water chamber 15 for cooling. The cooling water chamber 15 is provided with a water inlet joint 14 and a water outlet joint 8. The cooling water chamber 15 is provided with an intake channel 3 and an exhaust pulse channel 10; one end of the intake channel 3 is provided with an intake flange 1, and the intake flange 1 is connected to the compressor of the water-cooled turbocharger. The air intake passage 3 is connected with some intake collectors connected with the air inlet of the explosion-proof diesel engine; one end of the exhaust pulse passage 10 is provided with an exhaust flange 7 connected with the turbine of the water-cooled turbocharger, and the discharge The gas pulse channel 10 is connected with several exhaust collectors connected with the exhaust port of the explosion-proof diesel engine.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com