Method for fabricating rainbow film or paper through direct plating

A manufacturing method and rainbow film technology, which are applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of effect deviation, difficulty in adjusting the surface thickness position, etc., so as to reduce the production cost and achieve the best effect. Optimum, the effect of simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

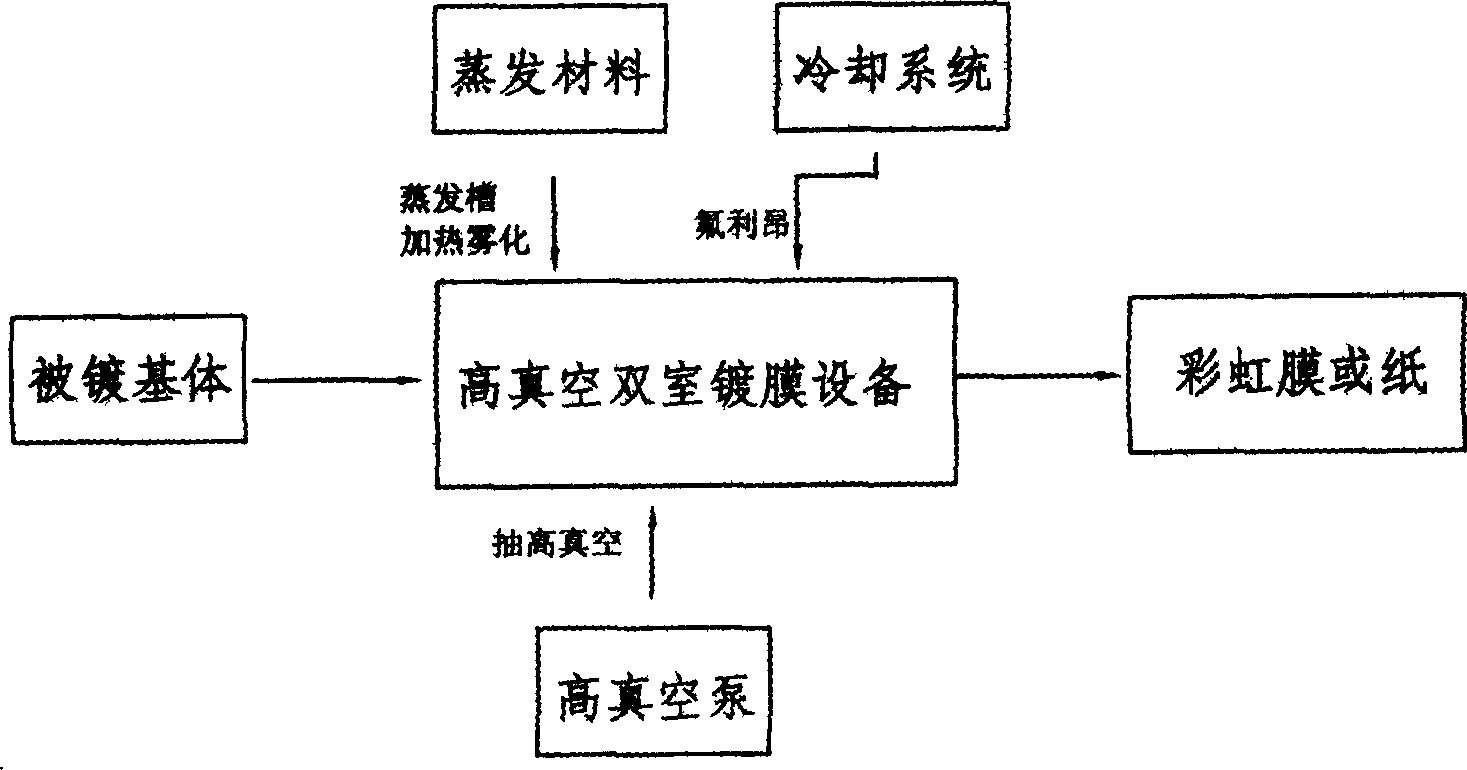

[0025] The manufacturing method of direct plating iridescent film is carried out according to the following technological process:

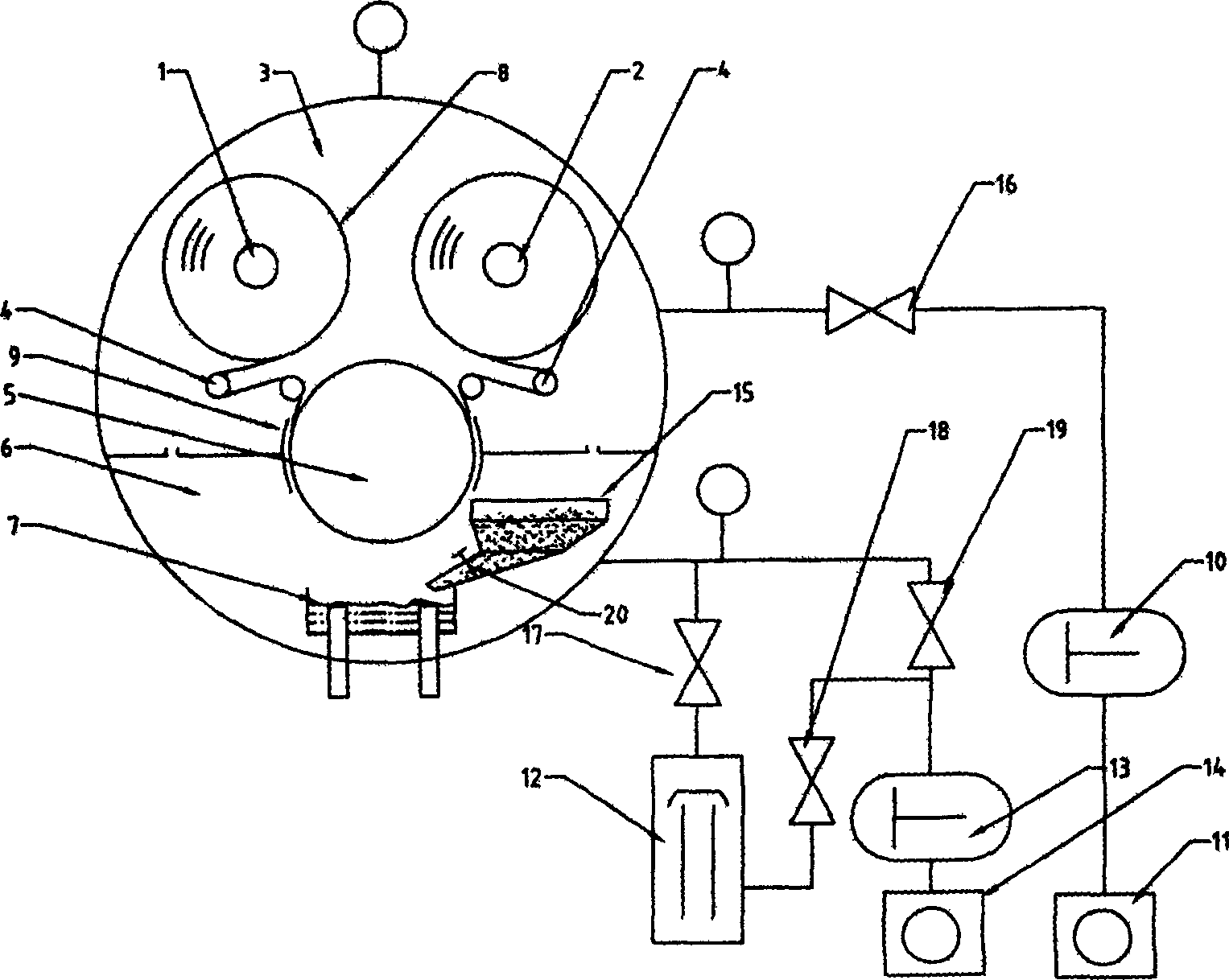

[0026] a. Put the plastic film 8 into the two take-up and take-up rolls 1 and 2 in the winding chamber of a high-vacuum double-chamber coating equipment, and let the plastic film 8 start from one of the take-up and take-up rolls 1 through successively from The moving roller 4, the central cooling drum 5, and the driven roller 4 are rewound to another rewinding and unwinding roller 2, the Freon forced refrigeration system is started, and the air circuit is connected;

[0027] B. Put zinc sulfide in the funnel container 15 and the evaporation tank 7 of the evaporation chamber 6 of the high-vacuum double-chamber coating equipment;

[0028] c. Turn on the extraction vacuum equipment 10, 11, 12, 13, 14, extract the vacuum to the winding chamber 3 and the evaporation chamber 6, and under the premise of ensuring that there is a certain vacuum pressure d...

Embodiment 2

[0035] The manufacturing method of direct-coated rainbow paper is carried out according to the following technological process:

[0036] a. Put the roll paper 8 into the two take-up and take-up rollers 1 and 2 in the winding chamber of a high-vacuum double-chamber coating equipment, and let the roll paper 8 pass through the driven rollers sequentially from one of the take-up and take-up rollers 1. Roller 4, central cooling drum 5, and driven roller 4 are rewound to another rewinding and unwinding roller 2, the Freon forced refrigeration system is started, and the gas circuit is connected;

[0037] B, put magnesium fluoride in the funnel container 15 and the evaporation tank 7 of the evaporation chamber 6 of the high-vacuum double-chamber coating equipment;

[0038] c. Turn on the extraction vacuum equipment 10, 11, 12, 13, 14, extract the vacuum to the winding chamber 3 and the evaporation chamber 6, and under the premise of ensuring that there is a certain vacuum pressure dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com