Method for purifying and refining ethyl acetate in high purity

A technology of ethyl acetate and a refining method, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of increasing energy consumption and increasing production costs, and achieve stable operation, stable operating temperature, The effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

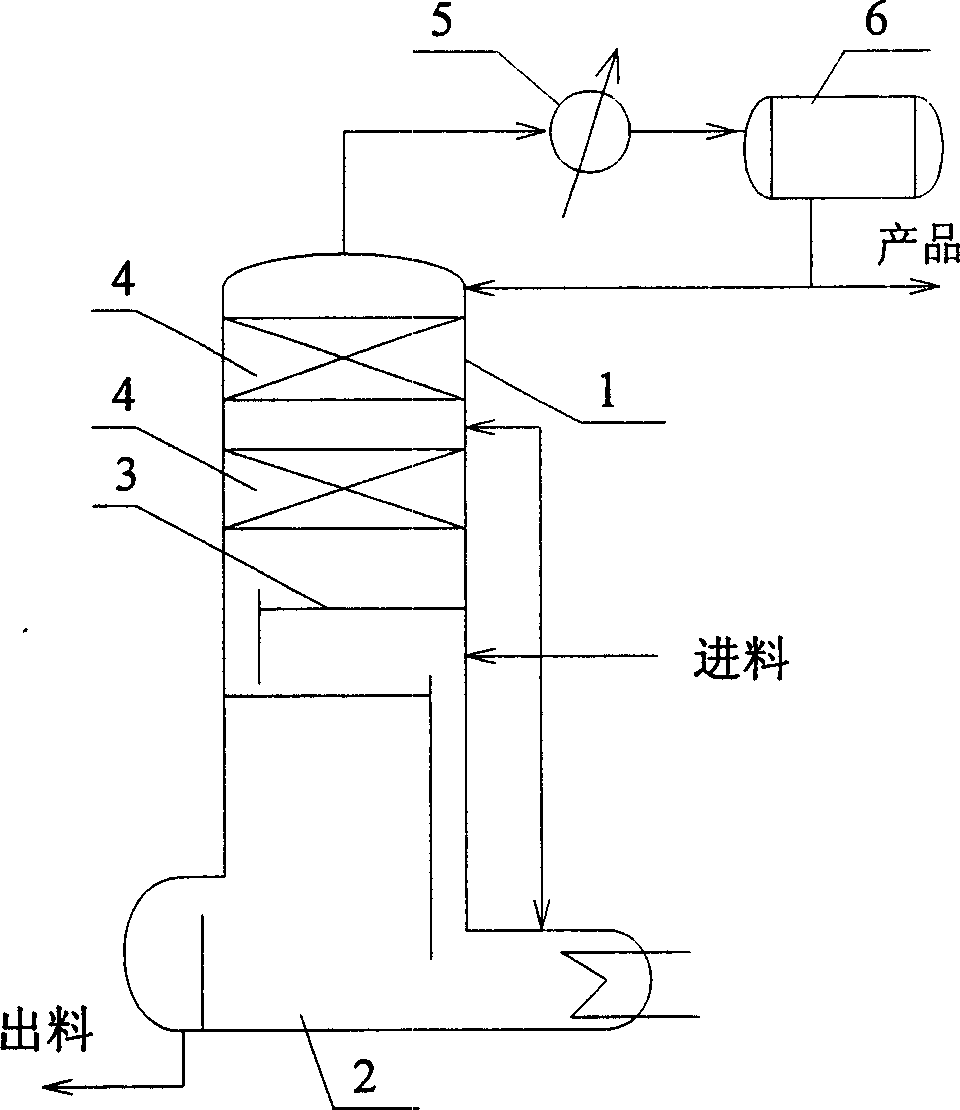

Image

Examples

Embodiment 1

[0022] The feed components and proportion (weight) are: 98.9% ethyl acetate, 1.0% acidity (calculated as acetic acid), 0.08% alcohol (calculated as ethanol), and 0.02% moisture. According to the above requirements, select the stainless steel sheet filler punching and corrugation with material codes 304 and 316L respectively. In the embodiment, three metal trays whose material code is 316L and a kettle-type reboiler with an overflow baffle are used. Feed from the 2nd tray. Refer to Table 1 for the operating index and results of Example 1.

[0023] In the embodiments of the present invention, stainless steel thin plates are used as the packing of the refining tower, which is not a limitation of the present invention, and the protection of the present invention is based on the claims.

[0024]

Embodiment 2

[0026] Feed components and proportioning (weight) are: ethyl acetate 99.1%, acidity (calculated as acetic acid) 0.79%, alcohol (calculated as ethanol) 0.09%, moisture 0.02%, methyl acetate 10ppm. According to the above requirements, select stainless steel sheet fillers with appropriate thickness and material codes 304 and 316L for punching and corrugation. In the embodiment, three metal trays whose material code is 316L and a kettle-type reboiler with an overflow baffle are used. The packing is filled in two stages, and the material is fed from between the two stages of packing. Refer to Table 2 for the operational index and results of Example 2.

[0027] Column type and reboiler type

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com