Nonreciprocal circuit element

A technology of circuit components and components, which is applied in the field of non-reciprocal circuit components, can solve the problems of high cost, large number of components, and inability to miniaturize, etc., and achieve the effects of excellent productivity, small number of components, and improved assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

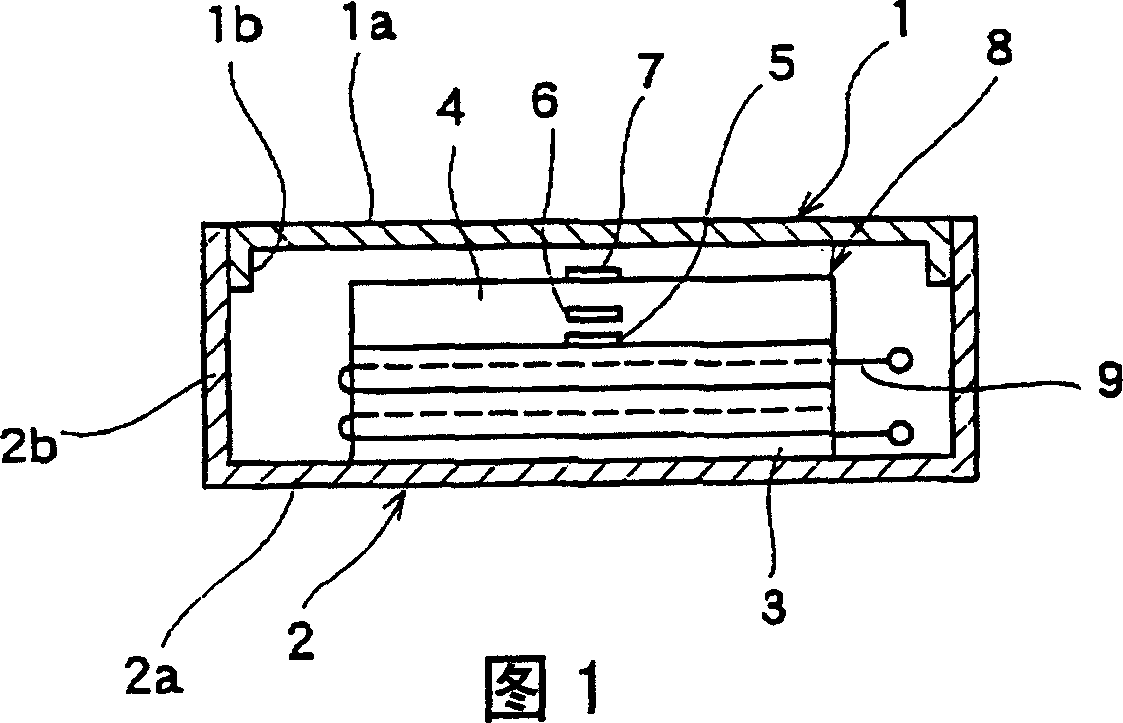

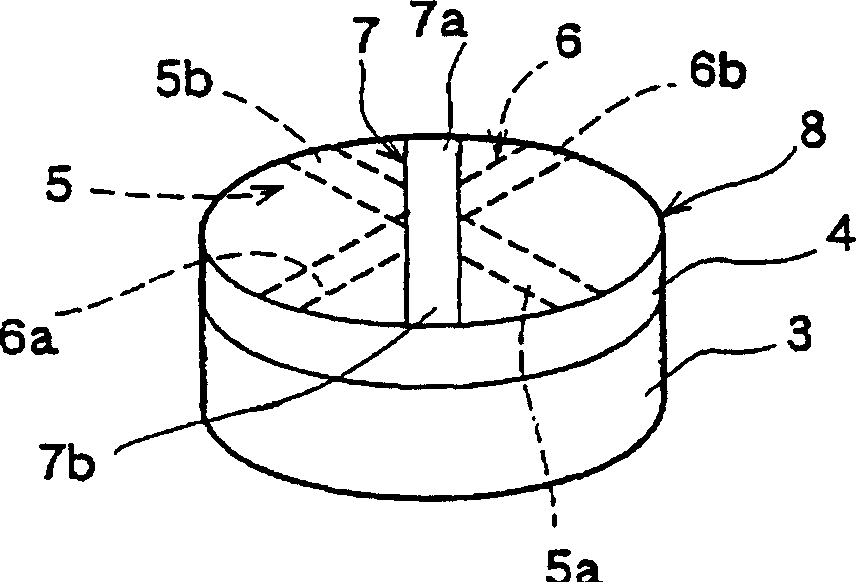

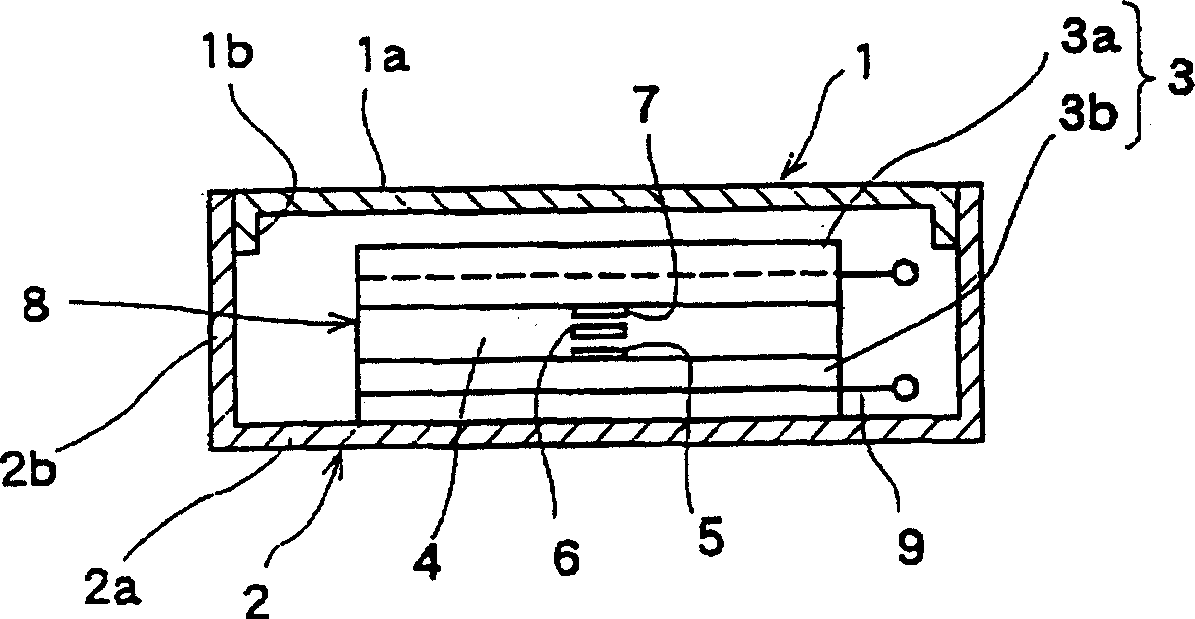

[0029] The non-reciprocal circuit element of the present invention is described, and Fig. 1 is a sectional view of main parts of the first embodiment of the non-reciprocal circuit element of the present invention, figure 2 It is a perspective view of a ferrite component and a dielectric body of the first embodiment of the non-reciprocal circuit element of the present invention, image 3 It is a sectional view of main parts of the second embodiment of the non-reciprocal circuit element of the present invention, Figure 4 It is a perspective view of the ferrite component and the dielectric body of the second embodiment of the non-reciprocal circuit element of the present invention.

[0030] Then, based on Figure 1, figure 2 , to describe the structure of the first embodiment of the non-reciprocal circuit element of the present invention, the first yoke 1 made of magnetic plates (iron plates, etc.) is formed in a box shape or a U shape, and has a square upper plate 1a and a T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com