Device for the determination of flow parameters for a fluid and method for operating such a device

A parameter and fluid technology, applied in measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of high flow resistance and small airflow changes in long pipes, and achieve the goal of reducing measurement errors and optimizing airflow monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

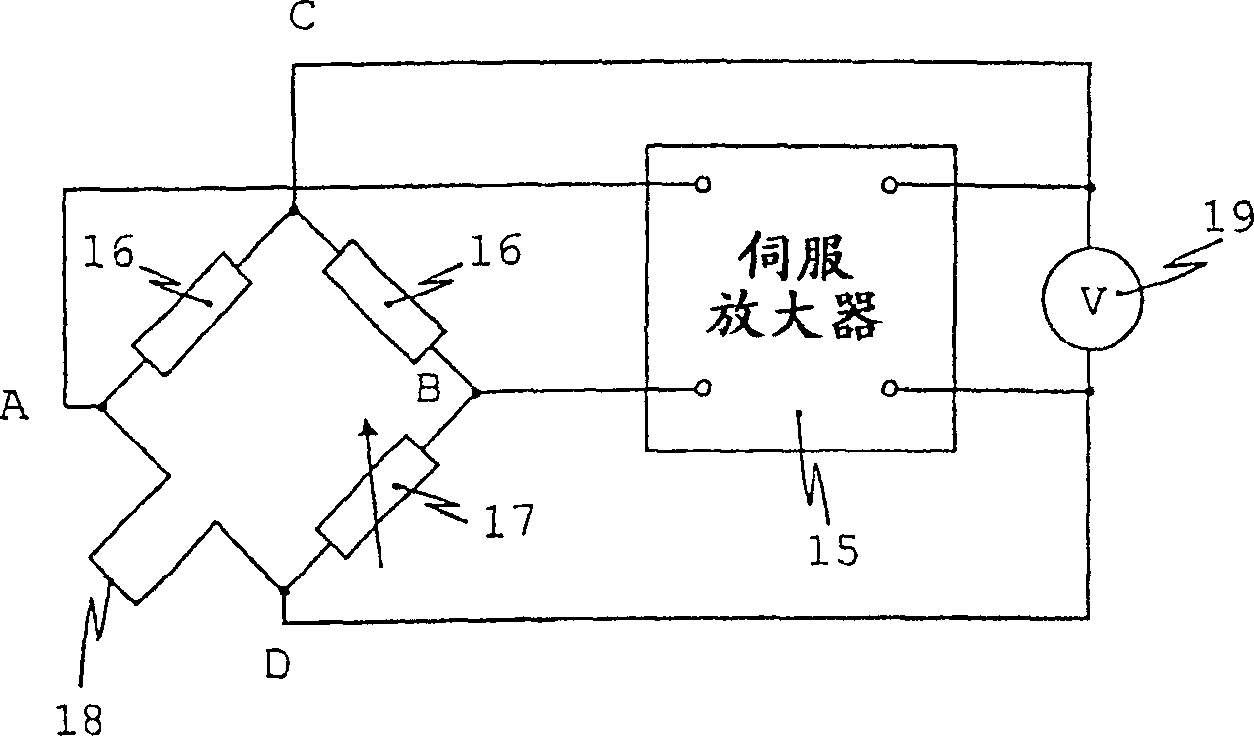

[0053] figure 1A schematic circuit diagram of a thermostatic anemometer according to the prior art is shown. The basic idea of the thermostatic mode of operation is to reduce the influence of the thermal inertia of the heating wire probe 18 by keeping the sensitive element 18 at a constant temperature (resistance) and using the heating current required for this as an indicator of the flow rate. Scaling. A Wheatstone bridge is used for this, in which the resistance of the heating wire and thus the temperature of the heating wire is kept constant by means of feedback. In the balanced state, a defined voltage is present at the vertical diagonal C-D of the bridge, which is supplied by the servo amplifier 15 . If the convective cooling on the probe 18 changes, a small voltage is generated on the horizontal diagonal A-B, which is amplified several times and fed back to the vertical diagonal C-D of the bridge. Here the polarity of this feedback voltage is chosen such that the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com