Method and device for measuring friction force of bearing under tiny load

A measurement method and a technology of a measurement device, which are applied in the field of torque measurement, can solve problems such as unstable friction and difficult friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

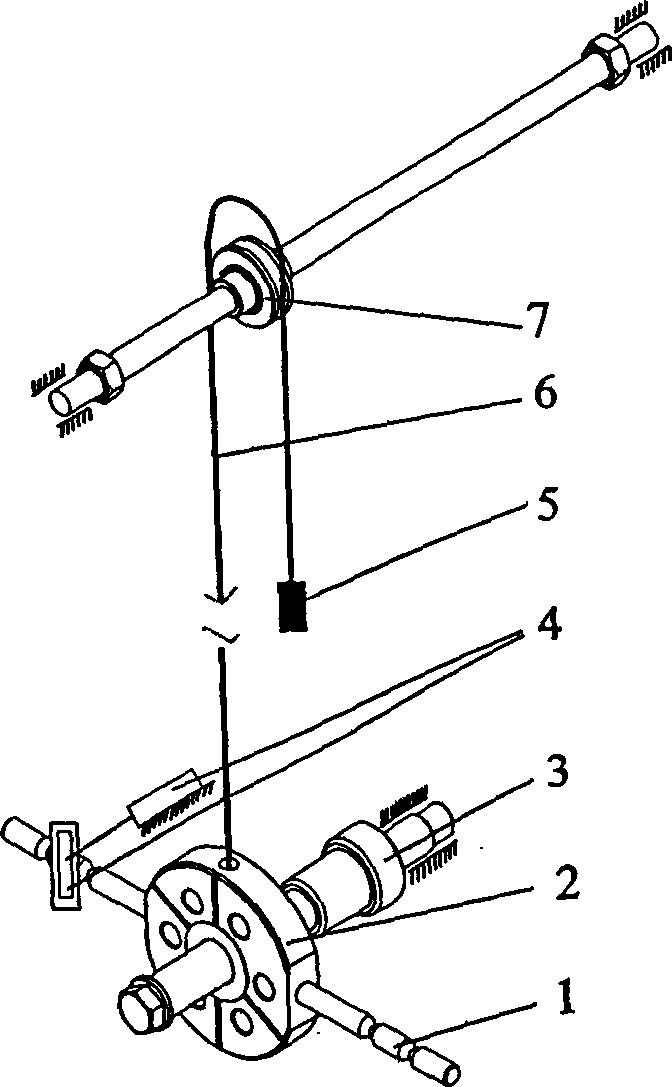

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

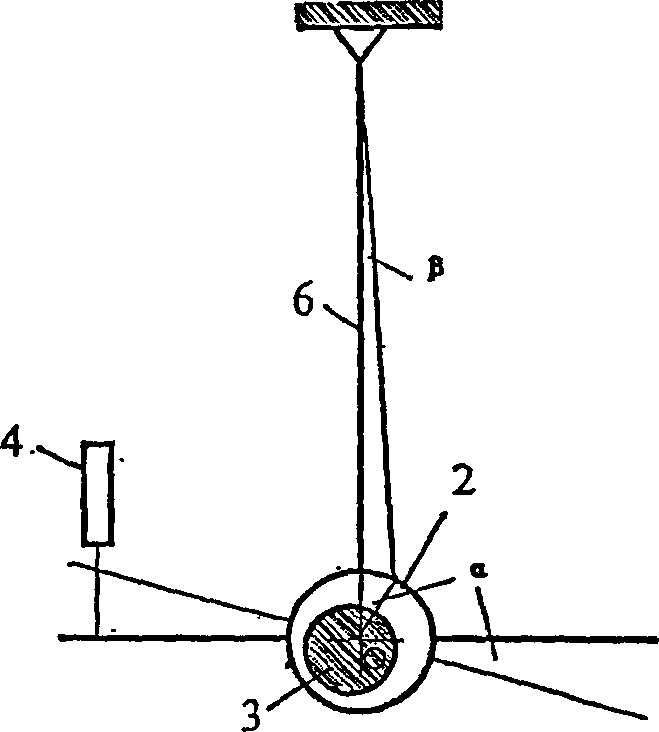

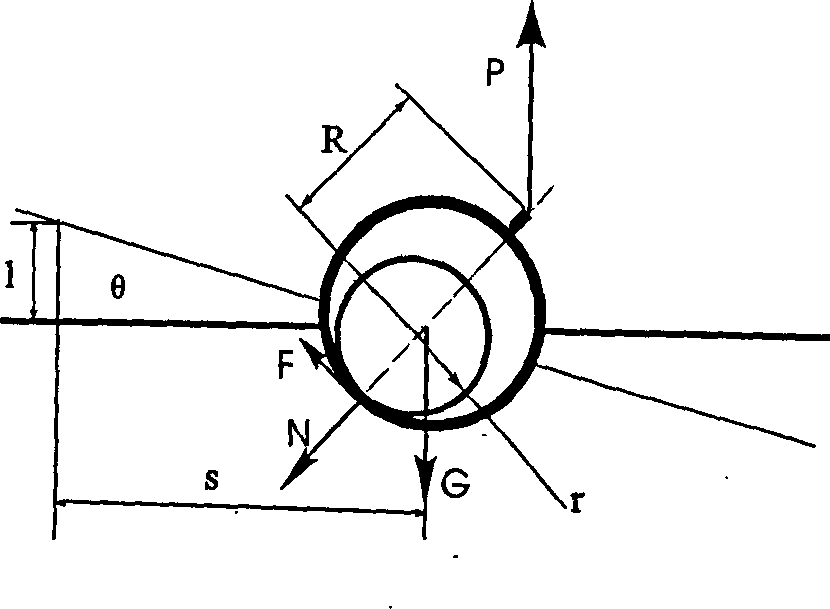

[0026] Such as figure 1 , figure 2 The schematic diagram of friction force measurement is shown, and the measurement steps are as follows:

[0027] 1) The method of measuring the friction force is to use the principle of leverage to convert the friction torque between the tested sliding bearing and the rotating shaft or between the inner and outer rings of the tested rolling bearing into the rotation angle through the measuring frame suspended above the rotating shaft, and use the force point After the tension is balanced, its rotation angle will remain balanced, and the rotation angle and frictional moment will maintain an approximately linear relationship within a small angle < 5°, so that the error does not exceed 5‰;

[0028] 2) The force is loaded from above, and the load force line is connected to the pulley, and the load is realized by utilizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com