Method for washing 4A zeolite crystal

A washing method and zeolite technology, which are applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of polluting environmental resources, difficult reuse and waste of waste water, etc., and achieve water resources conservation and economic benefits. and the effect of significant social benefits and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

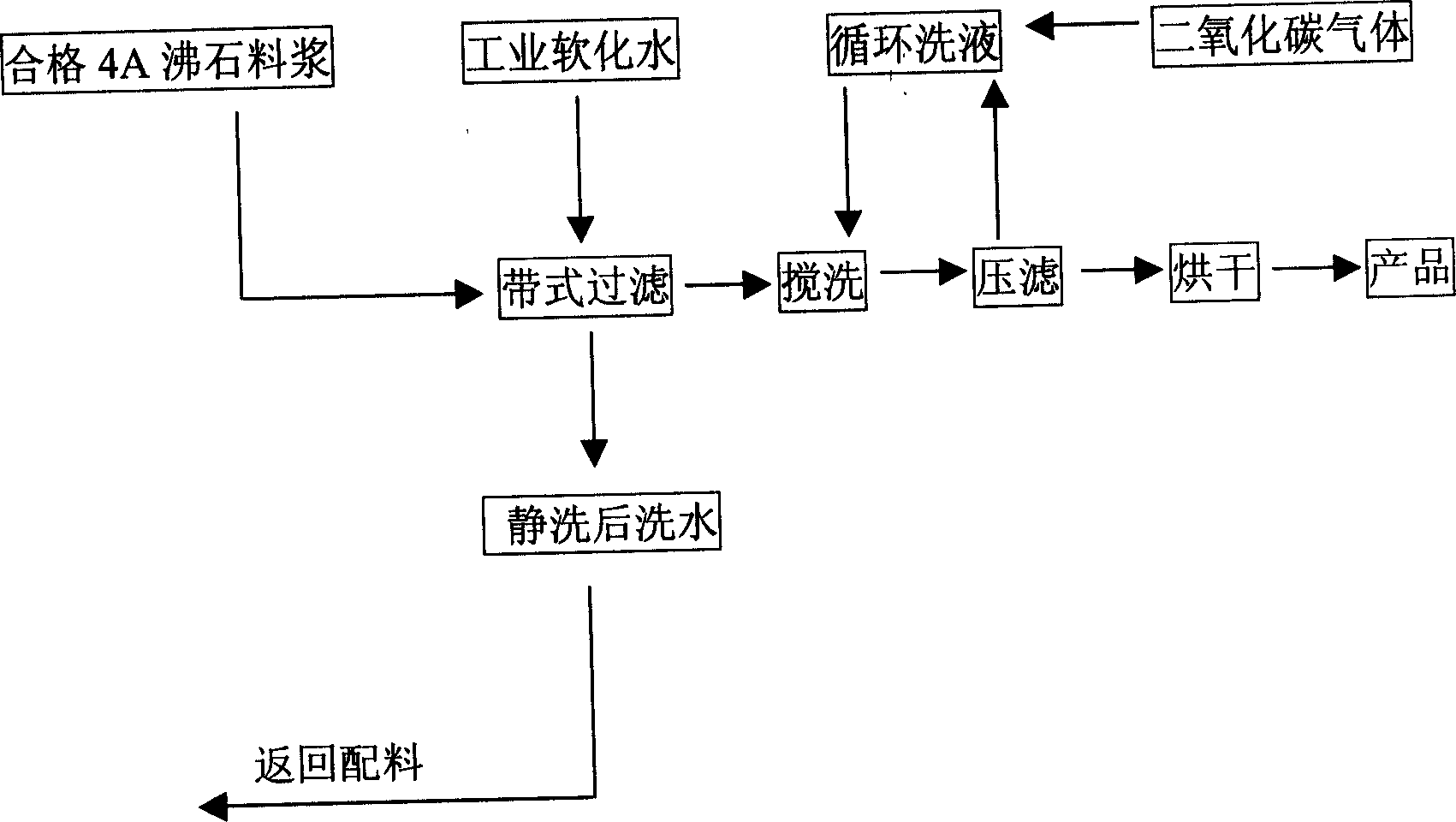

Image

Examples

Embodiment 1

[0015] The washing method of the 4A zeolite crystallization of the present invention comprises static washing and stirring washing, and carbon dioxide gas is added to the stirring liquid to prepare a circulating stirring liquid, and in the stirring liquid: N T 9g / l, N C -N T =3g / l (sodium carbonate 10g / l, sodium bicarbonate 4.5g / l), L / S=4, the washing temperature of the stirring solution is 20±5°C.

[0016] Follow the steps below for washing:

[0017] (1) statically wash the unwashed filter cake with 1 times normal temperature industrial demineralized water on the belt filter machine with 4A zeolite dry base as the base;

[0018] (2) Send the filter cake after static washing into the stirring tank for stirring.

[0019] The press filter cake after stirring and washing is dried to obtain 4A zeolite product, and the filtrate is returned to the stirring washing tank, and is recycled by adding carbon dioxide gas.

Embodiment 2

[0021] The washing method of the 4A zeolite crystallization of the present invention comprises static washing and stirring washing, and carbon dioxide gas is added to the stirring liquid to prepare a circulating stirring liquid, and in the stirring liquid: N T 11g / l, N C -N T =3.5g / l (sodium carbonate 12g / l, sodium bicarbonate 5g / l), L / S=3.5, the washing temperature of the stirring liquid is 25±3°C.

[0022] Follow the steps below for washing:

[0023] (1) statically wash the unwashed filter cake with 1.5 times normal temperature industrial demineralized water based on the 4A zeolite dry basis on the belt filter;

[0024] (2) Send the filter cake after static washing into the stirring tank for stirring.

[0025] The press filter cake after stirring and washing is dried to obtain 4A zeolite product, and the filtrate is returned to the stirring washing tank, and is recycled by adding carbon dioxide gas.

Embodiment 3

[0027] The washing method of the 4A zeolite crystallization of the present invention comprises static washing and stirring washing, and carbon dioxide gas is added to the stirring liquid to prepare a circulating stirring liquid, and in the stirring liquid: N T 10g / l, N C -N T =4g / l (sodium carbonate 11g / l, sodium bicarbonate 6g / l), L / S=4, and the washing temperature of the stirring solution is 22±5°C.

[0028] Follow the steps below for washing:

[0029] (1) statically wash the unwashed filter cake with 1 times normal temperature industrial demineralized water based on the 4A zeolite dry base on the belt filter;

[0030] (2) Send the filter cake after static washing into the stirring tank for stirring.

[0031] The press filter cake after stirring and washing is dried to obtain 4A zeolite product, and the filtrate is returned to the stirring washing tank, and is recycled by adding carbon dioxide gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com