Round shaped vertiplane

A technology for helicopters and fuselage, applied in the field of helicopters, can solve the problems of affecting the stability and speed of helicopters, complicated manufacture and installation of guide vanes, and large forward flight resistance, so as to achieve less floor space and reduce impact force. , the effect of protecting the safety of passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

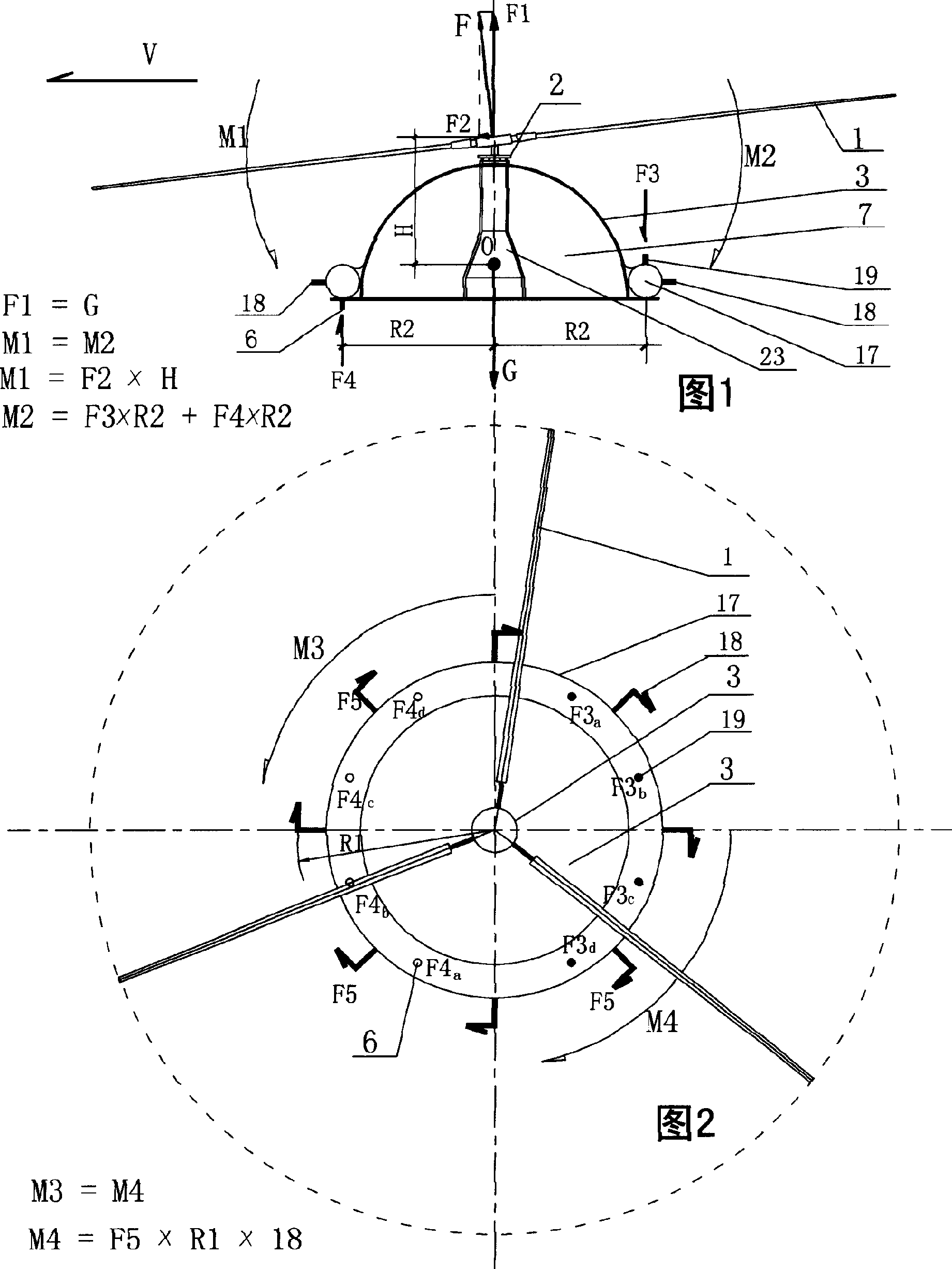

[0039] In Fig. 1, it shows the stressed state when the helicopter is flying forward, the main rotor disk is tilted forward under the action of the automatic tilter (2), and the acting force F of the main rotor to the fuselage can be decomposed into two parts F1 and F2. A force component, where F1 is balanced with the weight G of the helicopter. F2 makes the aircraft fly forward, but there is a distance H between F2 and the center of gravity O, which produces a force couple M1, but M1 makes the fuselage tilt forward. In order to reduce this inclination range, the present invention sprays air simultaneously through the downward solenoid valve nozzle (6) and the upward solenoid valve nozzle (19) installed on the gas storage ring tank (17), and the force couple M2 produced can balance M1, thereby making When the helicopter changes from the hovering state to flying forward suddenly, the fuselage will not tilt forward excessively due to the lack of a horizontal tail to affect the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com