Automatic storage and transfer technology of cigarette stick shaped material

An automatic storage and rod-shaped technology, which is applied in the fields of tobacco, cigarette manufacturing, transportation and packaging, etc., can solve the problems of high equipment cost, increased manufacturing cost, residual odor of filter rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

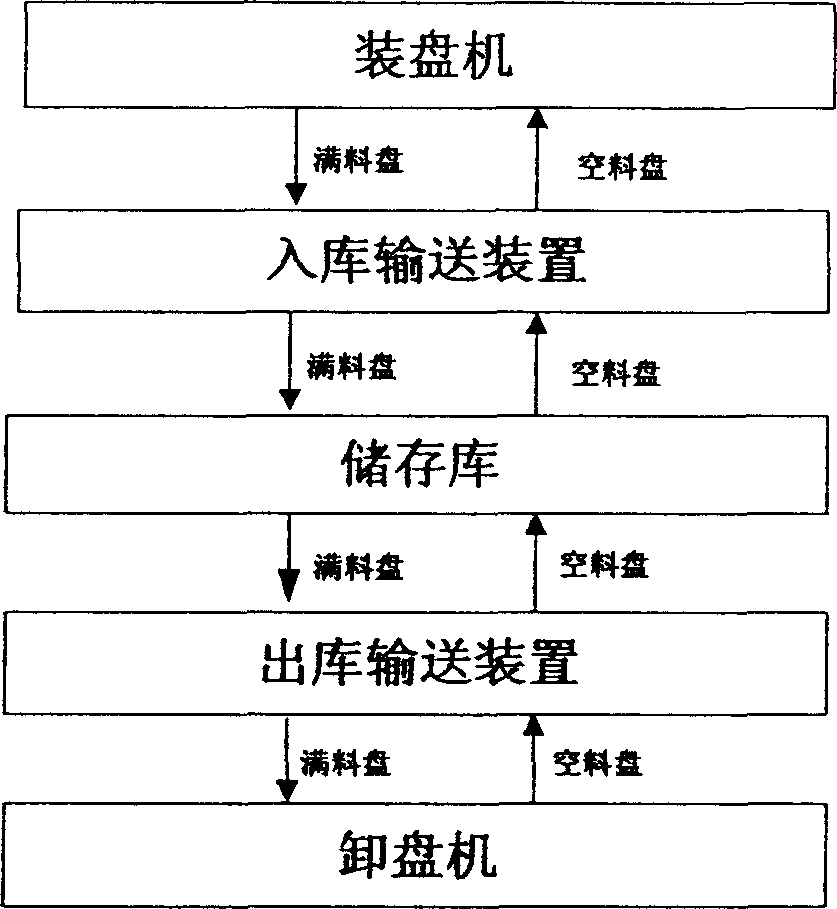

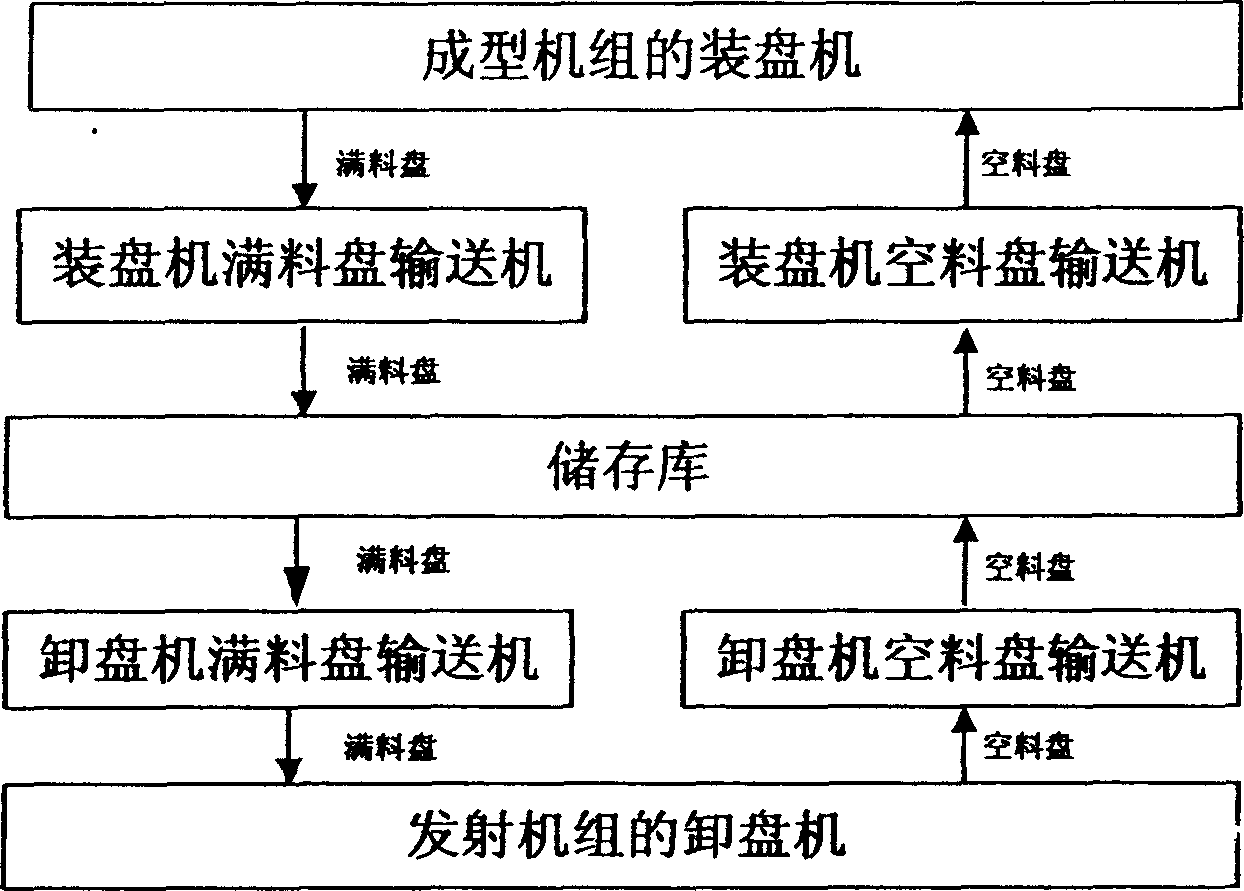

[0013] like figure 1 As shown, the process of the present invention adopts automatic control mode to transport the cigarette rod-shaped materials such as filter rods from the forming unit to the transmitter unit after storage and storage, including the storage process and the storage process, wherein the storage process The steps are as follows: Take the empty tray from the stocker and send it to the loader to pick up the bars from the forming unit, then take the full tray out of the loader and transfer it to the stocker The process steps of storage and delivery are as follows: take out the full tray filled with bar-shaped materials from the storage warehouse and transport it to the unloading machine to unload the tray, transport the unloaded rod-shaped material to the transmitter unit, and empty the empty tray. The trays are sent from the unloader to the storage warehouse for storage.

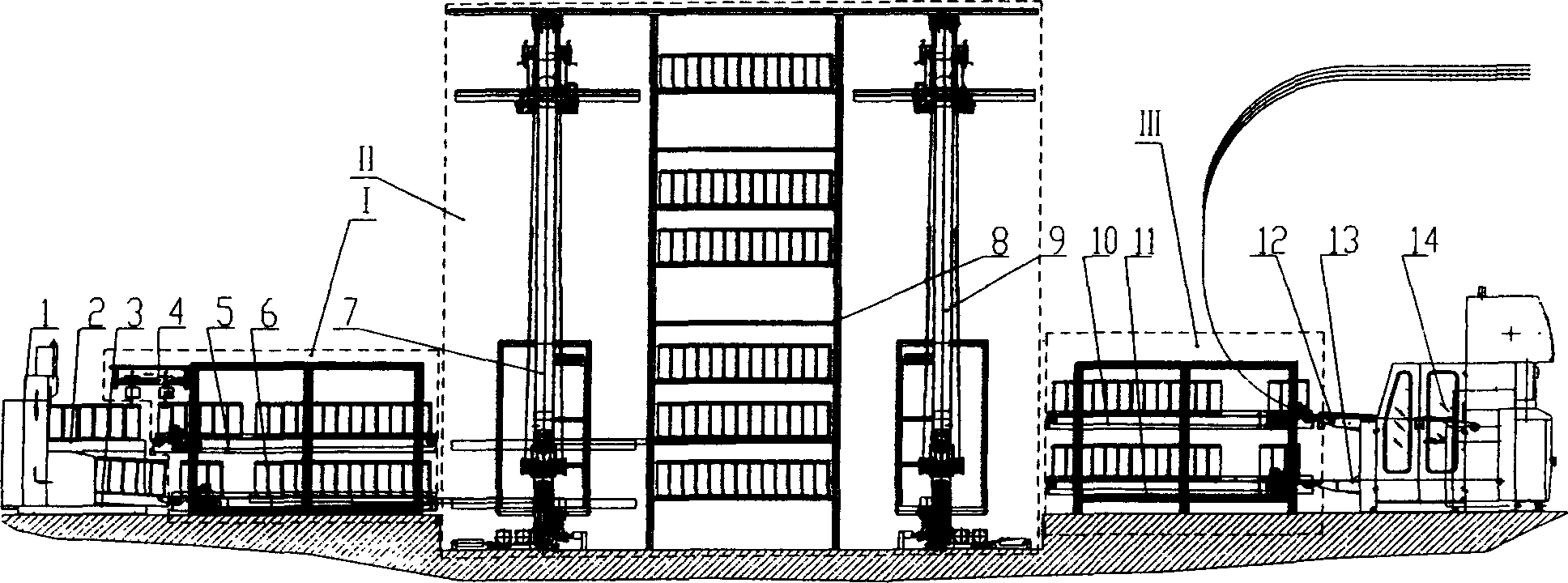

[0014] figure 2 Shown is a schematic diagram of the equipment structure of a specific e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com