Hull sensor position deviation guarantee method for motor direct driving washing machine using brushless DC motor

A Hall sensor, brushed DC motor technology, applied in the direction of electronic commutator, electronic commutation motor control, electrical components, etc., can solve the problems of high noise, motor temperature rise, motor rotation speed inaccuracy, etc., to improve washing performance and the effect of extending the life of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

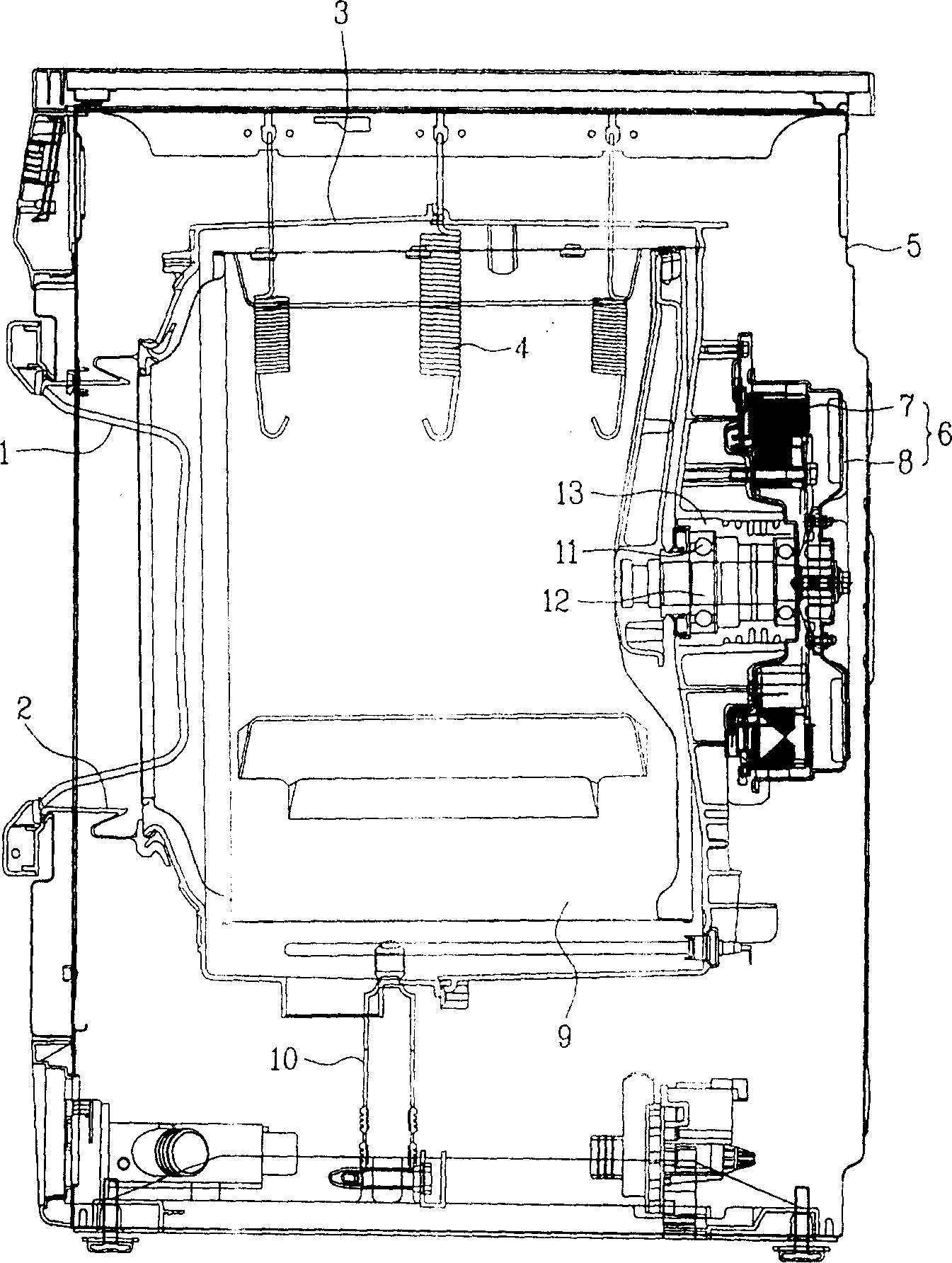

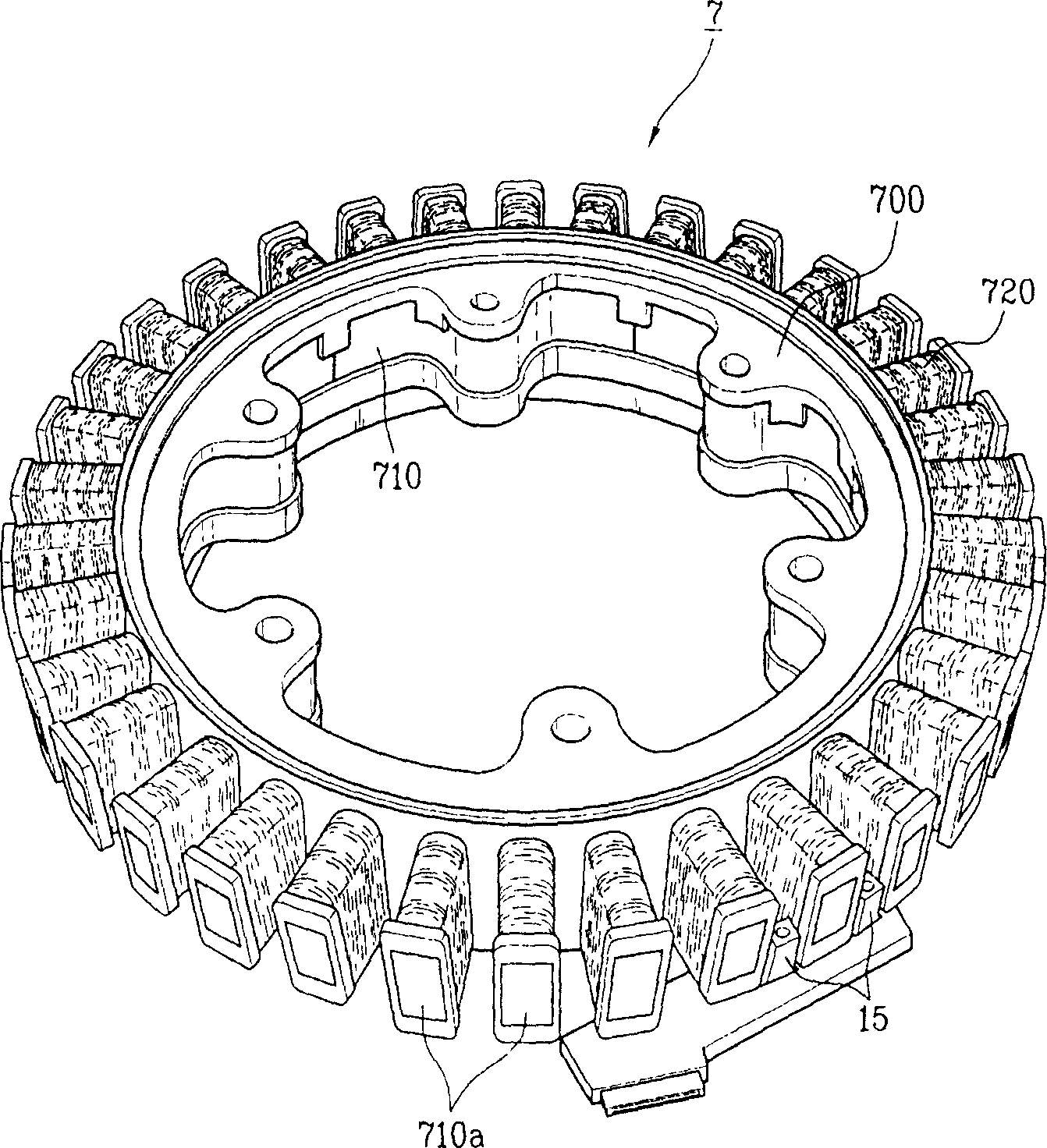

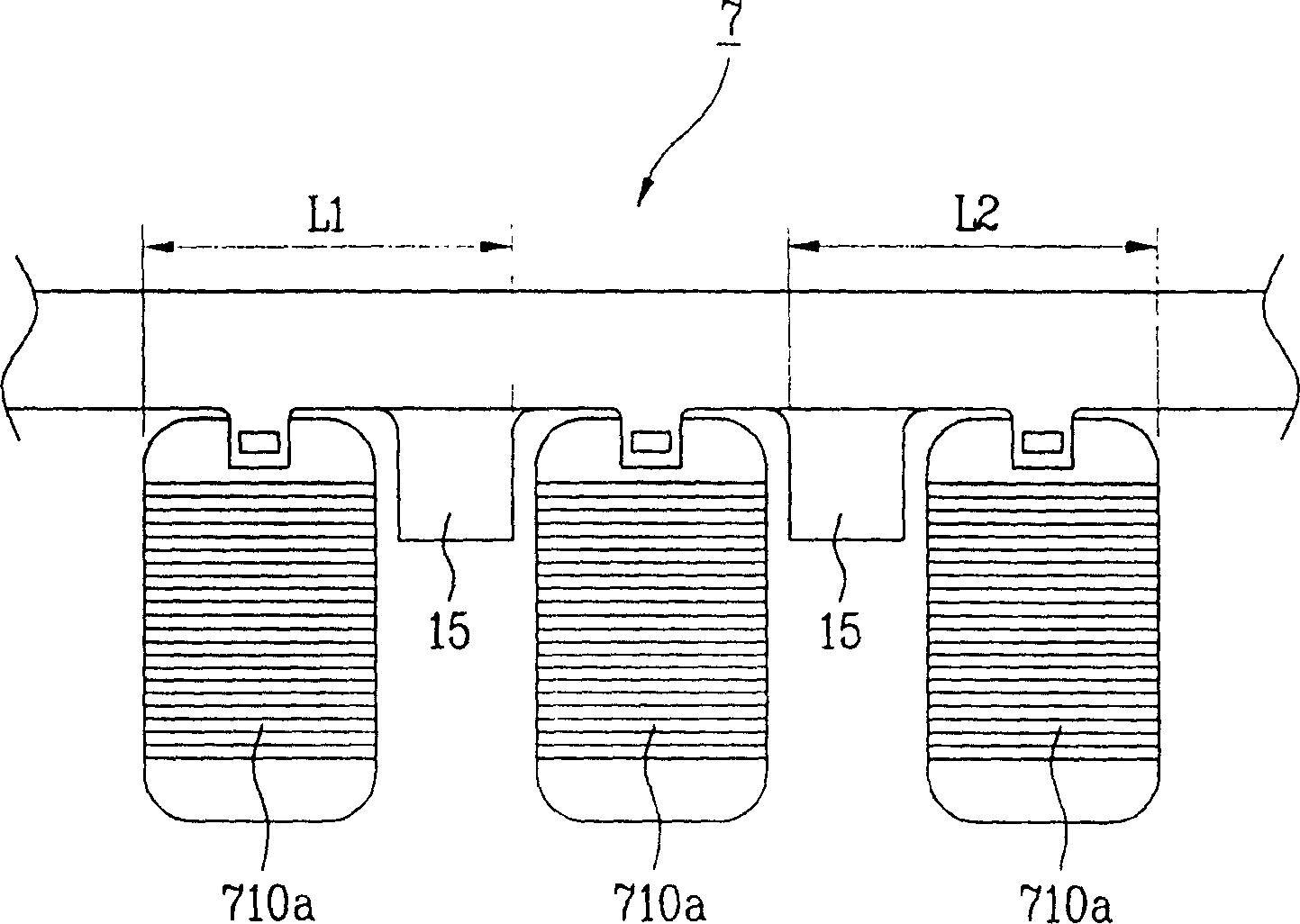

[0034] Below, referring to the attached Figure 1 to Figure 3 Examples of the present invention are described. In the present invention, a stator (7) equipped with a Hall sensor (15), a rotor (8) rotating around the stator (7), and a signal detected by the Hall sensor (15) are received when the rotor (8) rotates. And in the direct drive type automatic washing machine of the motor of the microcomputer (not shown) that controls the stator (7) power supply, the mechanism deviation of the above-mentioned Hall sensor (15) is guaranteed on the circuit, thus even if the Hall sensor (15) is not correct It can also correctly control the input power of the motor if it is set at the reference position of the mechanism.

[0035] The specific process of ensuring the position deviation of the Hall sensor is as follows.

[0036] First, the rotor (8) is artificially rotated on the production line using a jig or the like, and the counter electromotive force generated at this time and the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com