Self-suction rotary liquid spraying pump

A self-priming, liquid technology, applied in the direction of non-variable pumps, non-displacement pumps, pumps, etc., can solve the problems that the suction/lifting of liquid cannot be realized, and the suction impeller cannot effectively suck liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

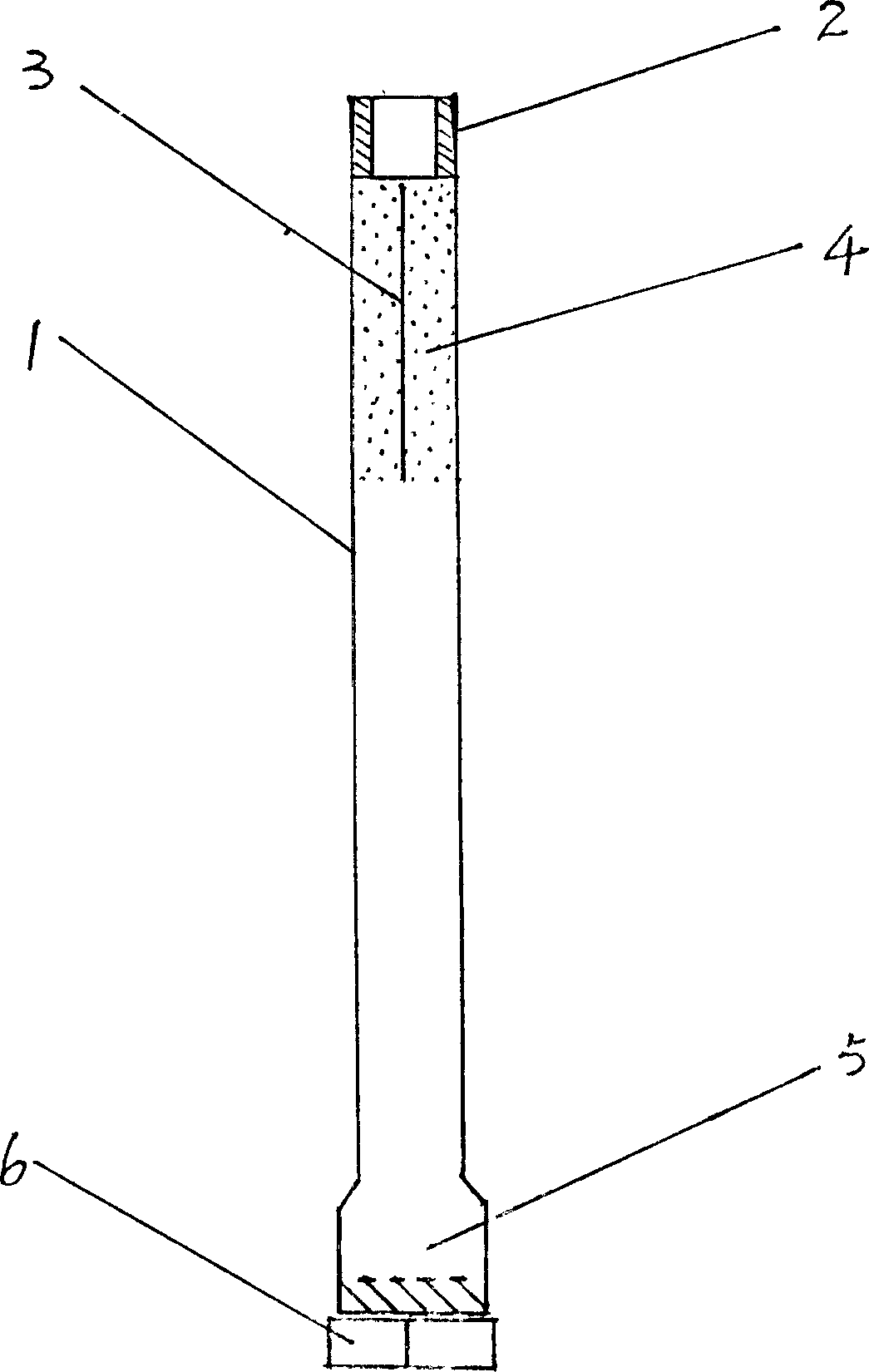

[0009] In the figure, one end of the straight pipe (1) is concentrically connected with a shaft connector (2). As shown in this illustration, it is in the shape of a self-tightening inner thread, and the inner thread is connected with an external power shaft configured separately. The outer threaded buckle is connected concentrically. The straight pipe (1) is in the shape of a concentric circular pipe body, and a plurality of small spray holes are evenly opened around the upper part of the pipe body to form a spray hole section (4), corresponding to the height of the spray hole section (4) in the lumen , a group of concentrically fixed core plates (3), shown as a straight plate structure in this illustration. The distraction plate (3) evenly separates the inner cavity of the straight pipe and makes it into a shape of up and down diameters, and the distraction plate (3) is composed of a straight plate passing through the center / several straight plates evenly distributed and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com