Rock salt deposit horizontal chamber type oil-gas depot and its building method

A construction method and chamber technology, applied to mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as brine pollution, groundwater and environmental pollution, waste of crude oil, etc., and achieve less pollution, small vertical span, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

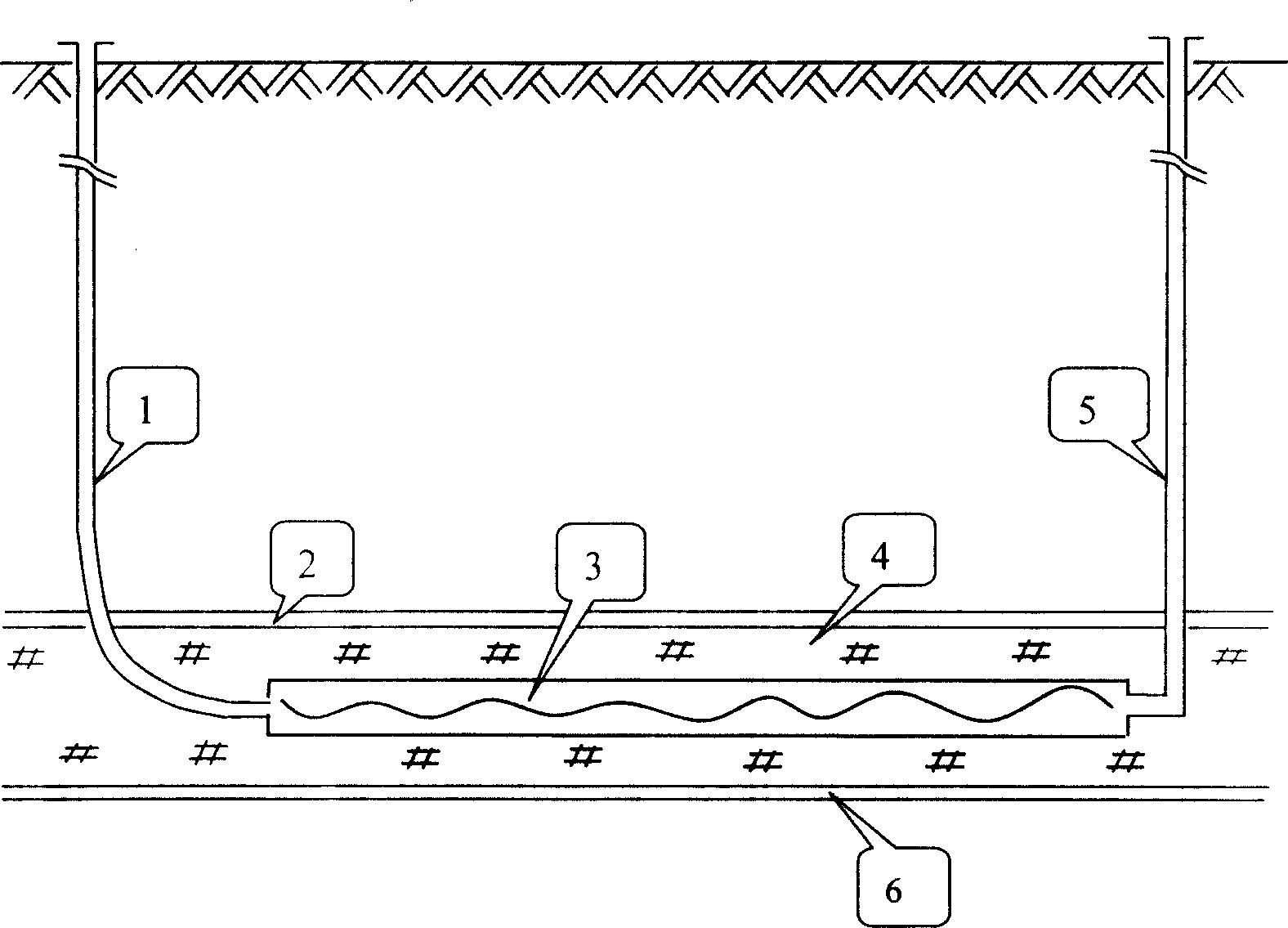

[0028] Such as figure 1 , 2 As shown, a horizontal chamber type oil and gas storage reservoir 3 of a salt rock deposit is chamber-shaped, and the chambers are distributed horizontally along the direction of the ore seam. 2 to 2 / 3, the chamber length is more than 10 times the diameter.

[0029] The single layer thickness of the salt rock mine in this embodiment is 80m, the designed chamber diameter is 50m, and the length in the horizontal direction is 500m.

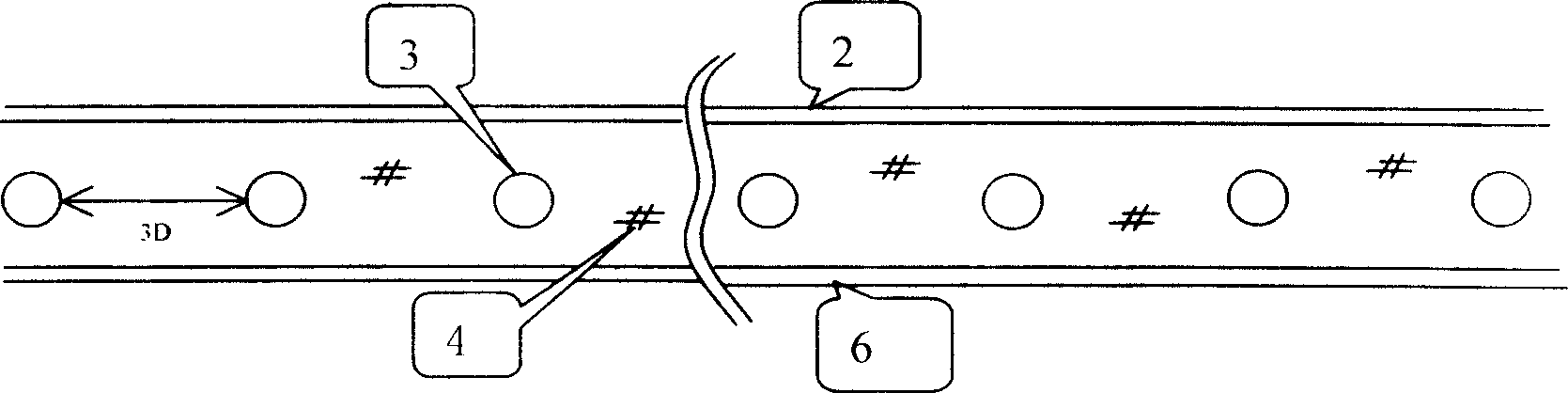

[0030] The capacity of a single level chamber is limited, to meet the requirements of a certain capacity, it is necessary to build chamber storage groups (see figure 2 ). The single-chamber reservoirs are arranged in the rock formation at a certain interval to form a group of oil and gas reservoirs. At least two horizontal chambers are arranged in the same rock formation to form a single-layer reservoir group.

[0031] According to the calculation of mechanical stability, for a single chamber with a diameter of D, th...

Embodiment 2

[0041] Such as figure 1 , 2 As shown, a horizontal chamber type oil and gas storage reservoir 3 of a salt rock deposit is chamber-shaped, and the shape of the cross-section of the chamber is approximately circular. The radius of the cavity depends on the occurrence characteristics and thickness of the salt rock deposit.

[0042] The single layer thickness of the salt rock mine in this embodiment is 60m, the designed chamber diameter is 30m, and the length in the horizontal direction is 300m.

[0043] The capacity of a single level chamber is limited, to meet the requirements of a certain capacity, it is necessary to build chamber storage groups (see figure 2 ). The single-chamber reservoirs are arranged in the rock formation at a certain interval to form a group of oil and gas reservoirs. At least two horizontal chambers are arranged in the same rock formation to form a single-layer reservoir group.

[0044] According to the calculation of mechanical stability, for a sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com