Well dynamic direct-driven plunger oil-well pump

A plunger-type, oil-pumping technology, used in pumps, wellbore/well components, machines/engines, etc., can solve the problems of large maintenance workload, high investment and maintenance costs, and narrow application scope, saving equipment The effect of capital investment, reducing the workload of adjusting parameters and changing pumps, and reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

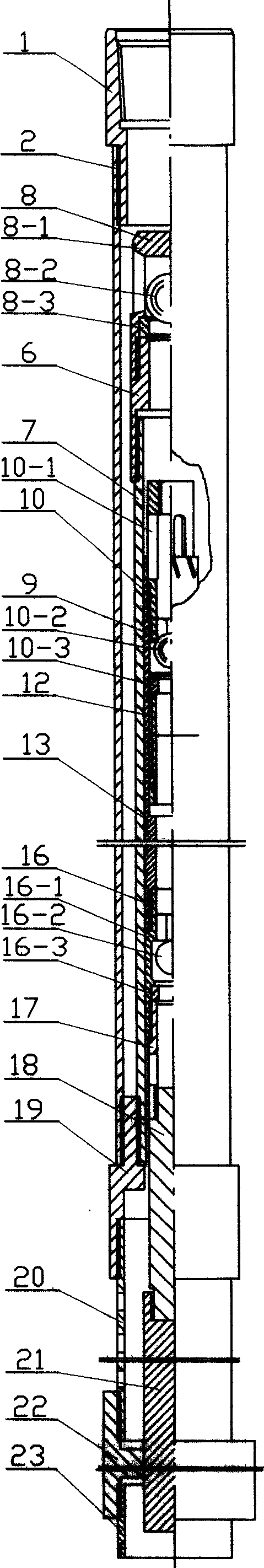

[0006] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment consists of the upper joint 1, the outer cylinder 2, the pump cylinder 7, the pump cylinder joint 6, the fixed valve assembly 8, the pump cylinder fixed joint 19, the plunger 13, the sand scraping cup 9, and the joint 12 , plunger upper valve assembly 10, plunger lower valve assembly 16, plunger oil inlet joint 17, connecting rod 18, motor stator 22, screen pipe 20, lower joint 23, motor mover 21; upper joint 1 The lower end of the outer cylinder 2 is fixedly connected with the upper end of the outer cylinder 2, the outer cylinder 2 is equipped with a pump cylinder 7, the upper end of the pump cylinder 7 is fixedly connected with the lower end of the pump cylinder joint 6, and the upper end of the pump cylinder joint 6 is connected with the fixed valve assembly 8 The fixed cover 8-1 is fixedly connected, the hole between the outer cylinder 2 and the pump cylinder 7 is fixed with...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 Describe this embodiment, the fixed valve assembly 8 of this embodiment is made up of fixed valve cover 8-1, fixed valve ball 8-2, fixed valve seat 8-3; Fixed valve seat 8-3 is contained in In the hole of fixed valve cover 8-1, fixed valve ball 8-2 is housed in the hole between fixed valve seat 8-3 and fixed valve cover 8-1. A fixed valve assembly 8 is fixed on the top of the pump barrel joint 6, and only when the lower end pressure is greater than the upper end pressure, the fixed valve ball 8-2 in the fixed valve assembly 8 can be opened, and the reverse pressure difference is then closed. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the valve assembly 10 on the plunger of this embodiment is composed of a valve cover 10-1 on the plunger, a valve ball 10-2 on the plunger, and a valve seat 10-3 on the plunger; the joint The upper end of 12 is equipped with the valve seat 10-3 on the plunger, and the upper end of the valve seat 10-3 on the plunger is equipped with the valve cover 10-1 on the plunger, and the hole of the valve cover 10-1 on the plunger is equipped with There are plungers 10-2 on Verball. The valve assembly 10 on the plunger moves with the plunger 13 in the pump barrel 7. Only when the pressure at the lower end is greater than the pressure at the upper end, the valve ball 10-2 on the valve in the valve assembly 10 on the plunger can be opened. The reverse differential is closed. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com