Hydraulic variable loading system for roller-plate coal mill

A hydraulic variable loading, coal mill technology, applied in cement production, grain processing, etc., can solve the problems of adjusting the grinding pressure of coal mills, wasting energy, and difficult to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

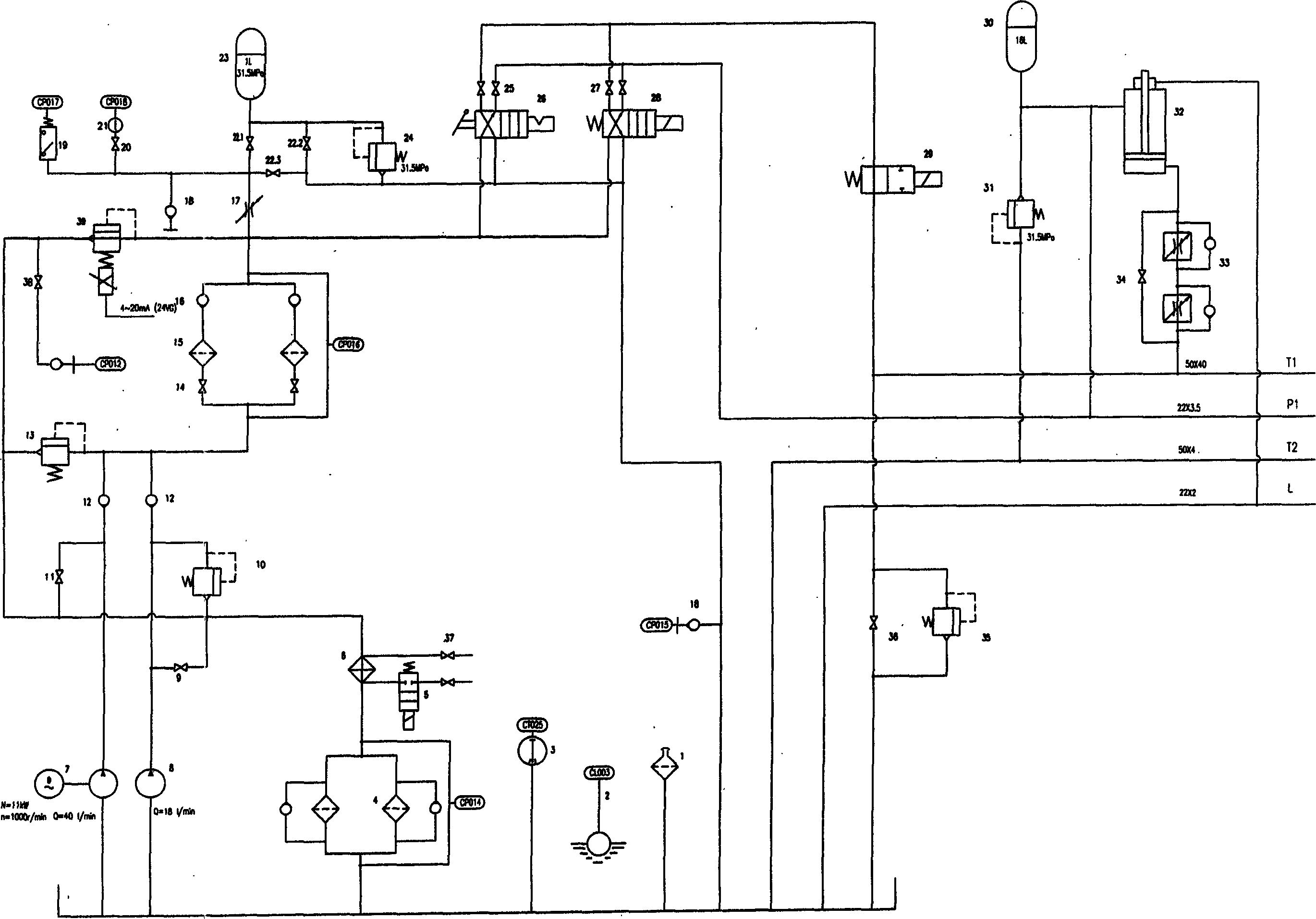

[0006] The whole system consists of filter 1, liquid level gauge 2, thermometer 3, two-way filter 4, two-position two-way solenoid valve 5, cooler 6, motor 7, double-connected pump 8, throttle valve 9, overflow valve 10, Throttle valve 11, one-way valve 12, overflow valve 13, throttle valve 14, high-pressure two-way filter 15, one-way valve 16, speed control valve 17, one-way valve 18, pressure transmitter 19, throttle valve 20, Pressure gauge 21, throttle valve 22, accumulator 23, overflow valve 24, throttle valve 25, two-position four-way manual reversing valve 26, throttle valve 27, two-position four-way electromagnetic reversing valve 28, Two-position two-way electromagnetic reversing valve 29, accumulator 30, overflow valve 31, hydraulic cylinder 32, speed control valve 33, throttle valve 34, overflow valve 35, throttle valve 36, throttle valve 37, throttle flow valve 38 and proportional relief valve 39, the motor 7 drives the double pump 8 to provide hydraulic kinetic en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com