Scanning probe microscope

A technology of scanning probe and microscope, which is applied in the field of scanning probe microscope, can solve the problems of short time, local probe technology tracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

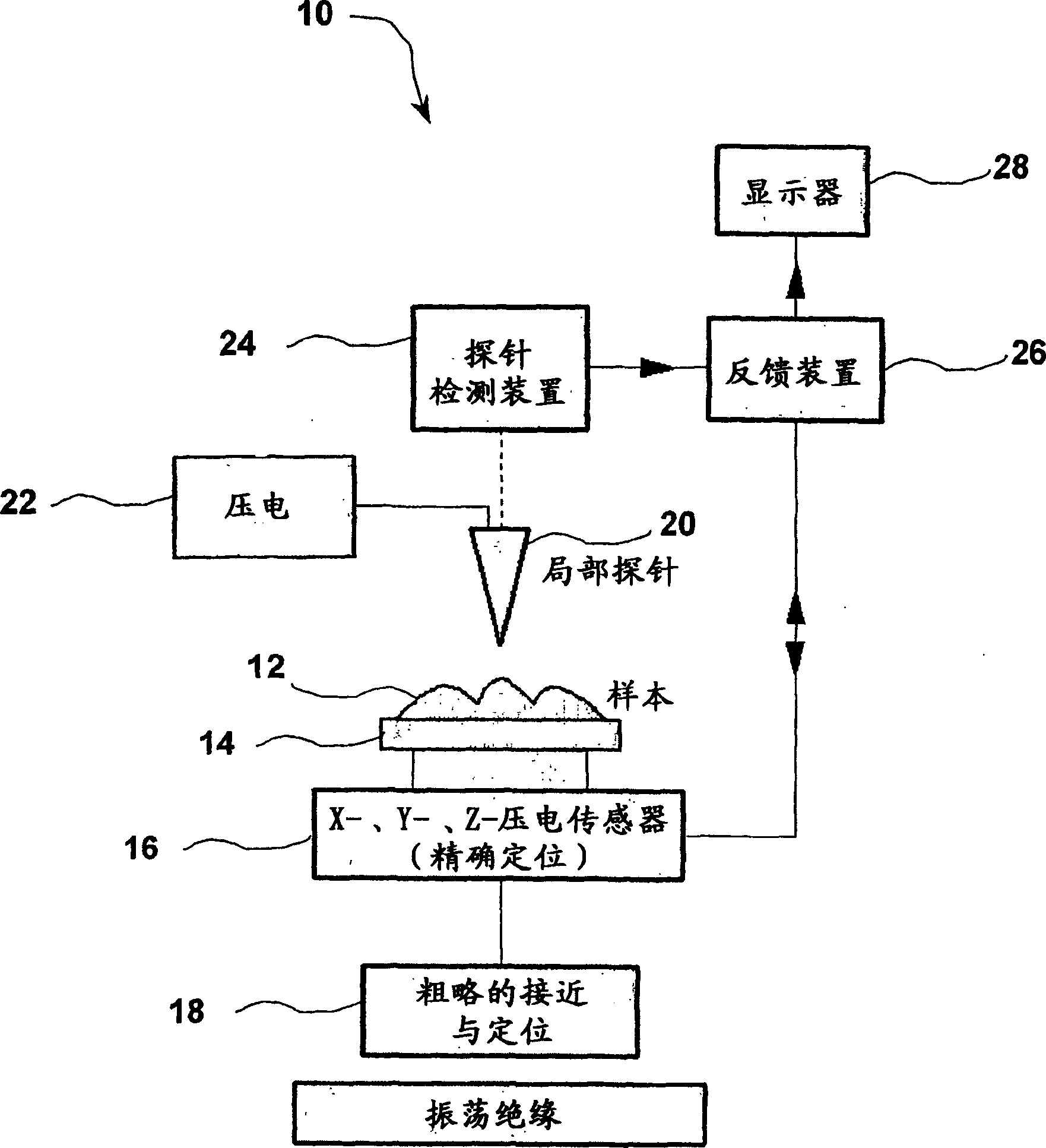

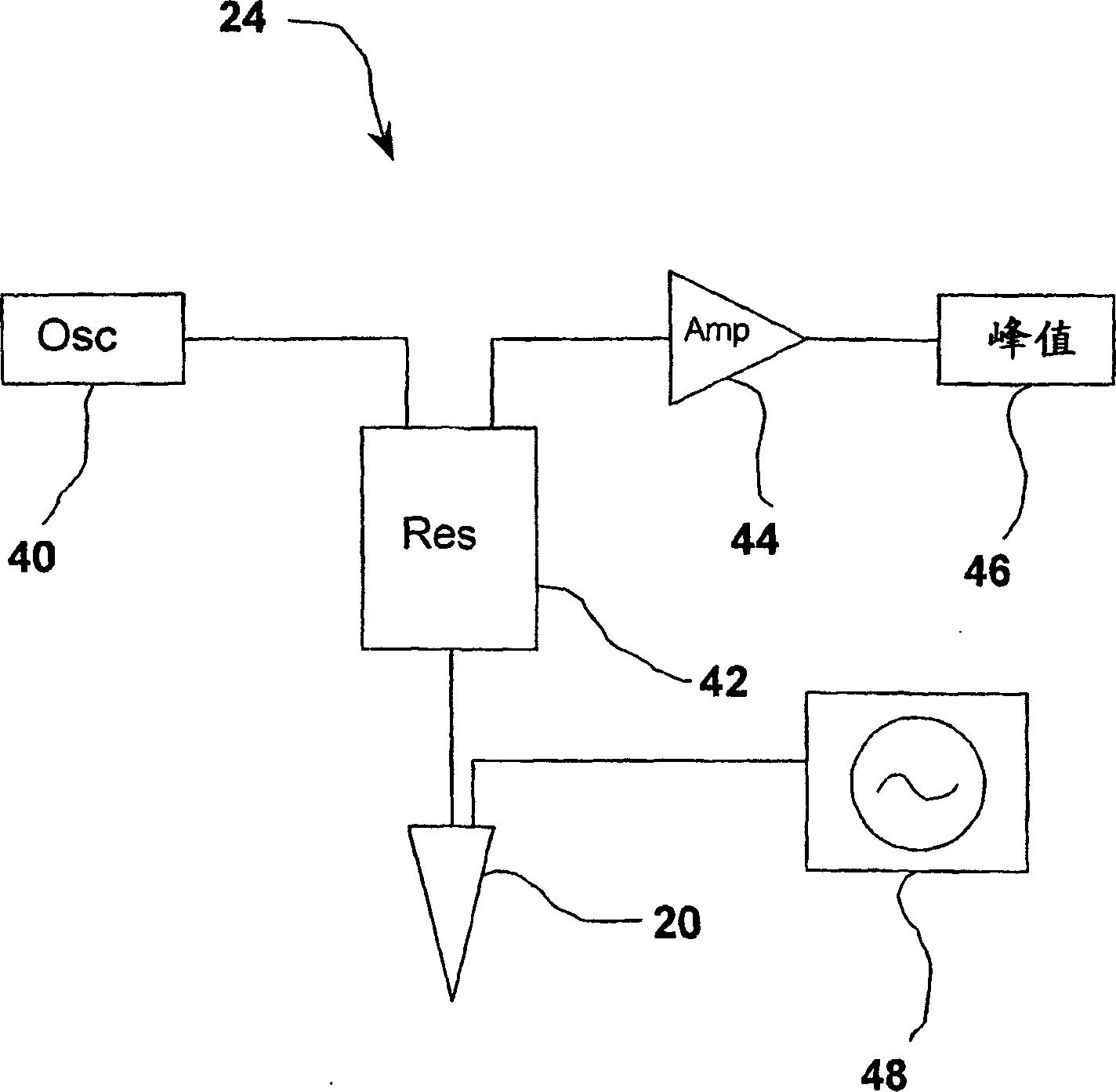

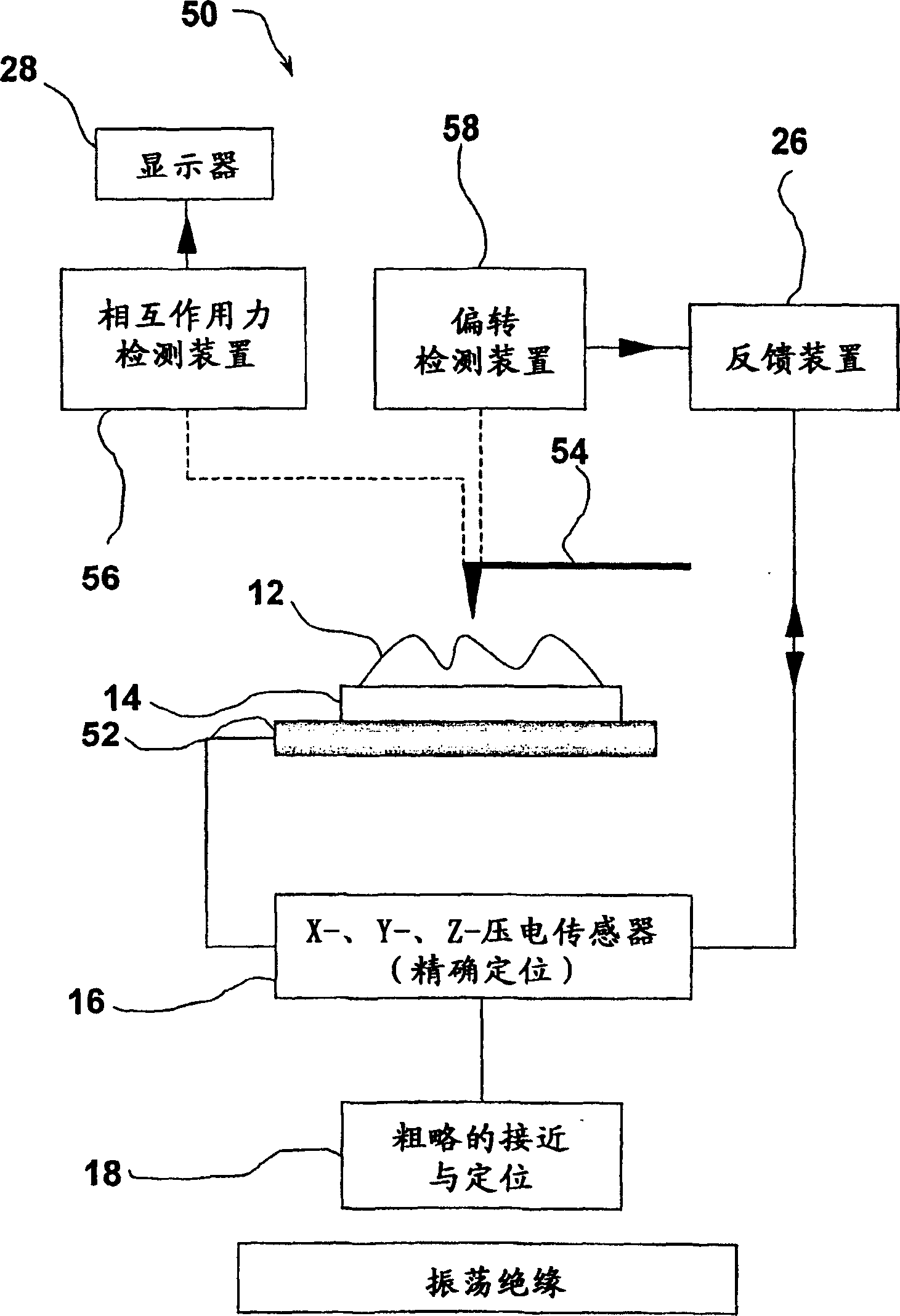

[0029] figure 1 An embodiment of a scanning capacitance microscope (SCM) of the present invention is shown. In Rev. Sci. Inst. 72 (6) "Zeptofarad" for Scanning Capacitance Microscopy (10 -21 ) Resolution Capacitive Sensors" describes existing SCM techniques and proves to be particularly useful when measuring 2D carrier profiles of semiconductor devices. As in the microscope described by Tran et al., figure 1The illustrated device 10 includes a ground plane 14 adapted to receive a sample 12 connected to a piezoelectric transducer 16 and a rough drive 18 . The metal probe 20 is connected to a second piezo drive 22 for driving the probe 20 at or near resonance, unlike any existing SCM technology drive. The first 16 or second 22 piezoelectric transducer drives the relative vertical motion of the probe 20 and sample 12 . In this embodiment it is a piezoelectric sensor 16 attached to the sample 12 . The device comprises a probe detection device 24, the detailed configuration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com