Method for removing foam from the washing container of a drum-type washing machine

A technology for a drum washing machine and a washing container, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problem that the sensor is not always available.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

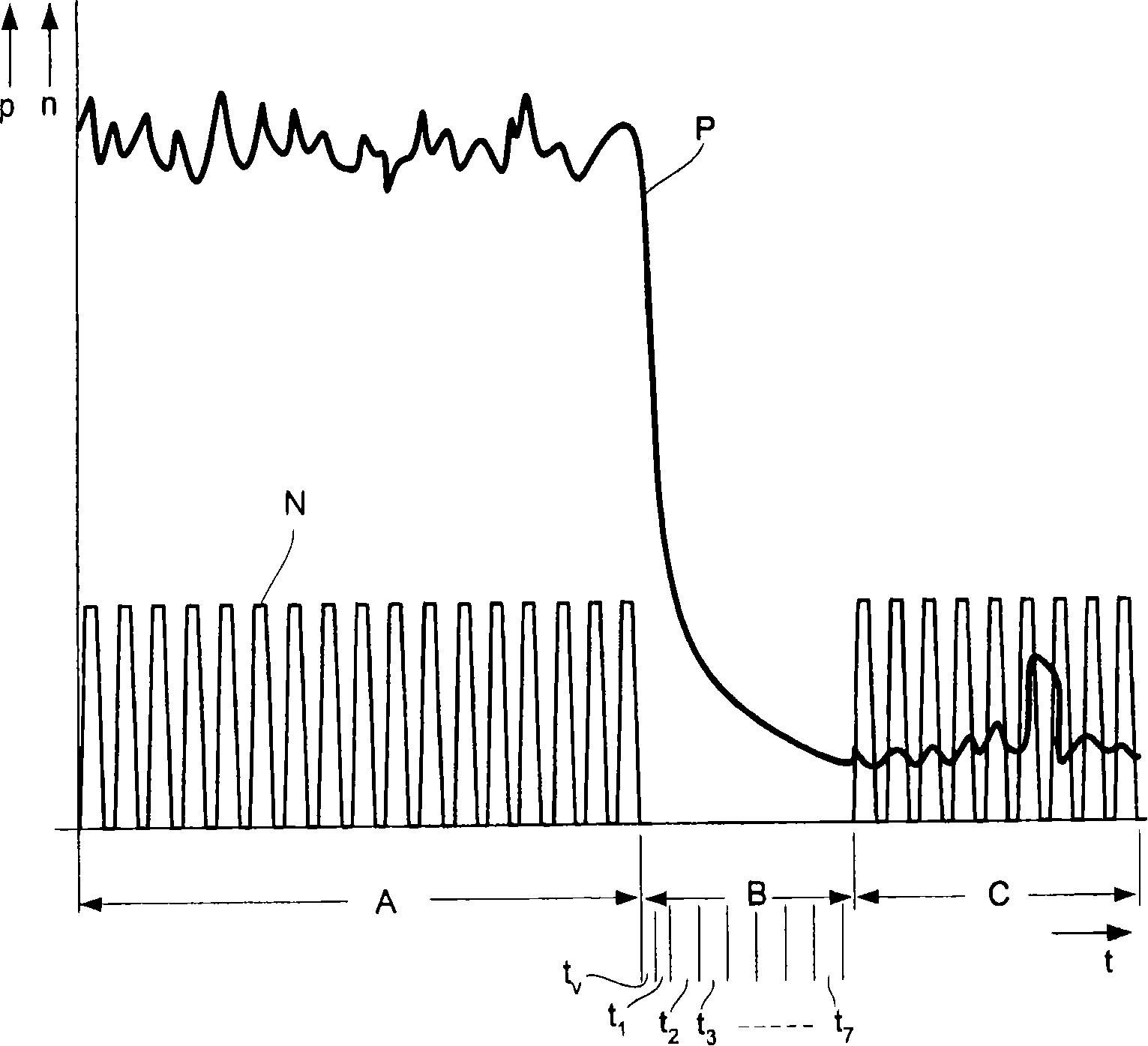

[0016] figure 1 Indicates section A before the start of the centrifugation program, ie the loosening phase. During the loosening phase, the washing drum is driven intermittently at the washing speed. This can have a change in direction of rotation. Speed peak N represented by a thin line 1 to N 17 Indicates intermittent drive of the laundry drum. Fluctuations in the liquid level in the washing container (thick line P) are relatively small during this phase. The withdrawal of liquid from the washing vessel after the loosening phase A causes the thick line P to drop very steeply almost continuously to 0. After the constant liquid level drop rate is determined in section B, the rotation speed of the washing drum is increased to the preselected centrifugal speed N S . A greater quantity of liquid is thus centrifuged from the laundry per unit of time than the pump can handle at the time. The liquid level in the washing container therefore rises slightly again in section D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com