Three-roller Y shaped prestressed rolling mill

A prestressing and rolling mill technology, applied in the direction of metal rolling stand, metal rolling mill stand, driving device for metal rolling mill, etc. Achieve the effect of advanced structure, compact rolling mill structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

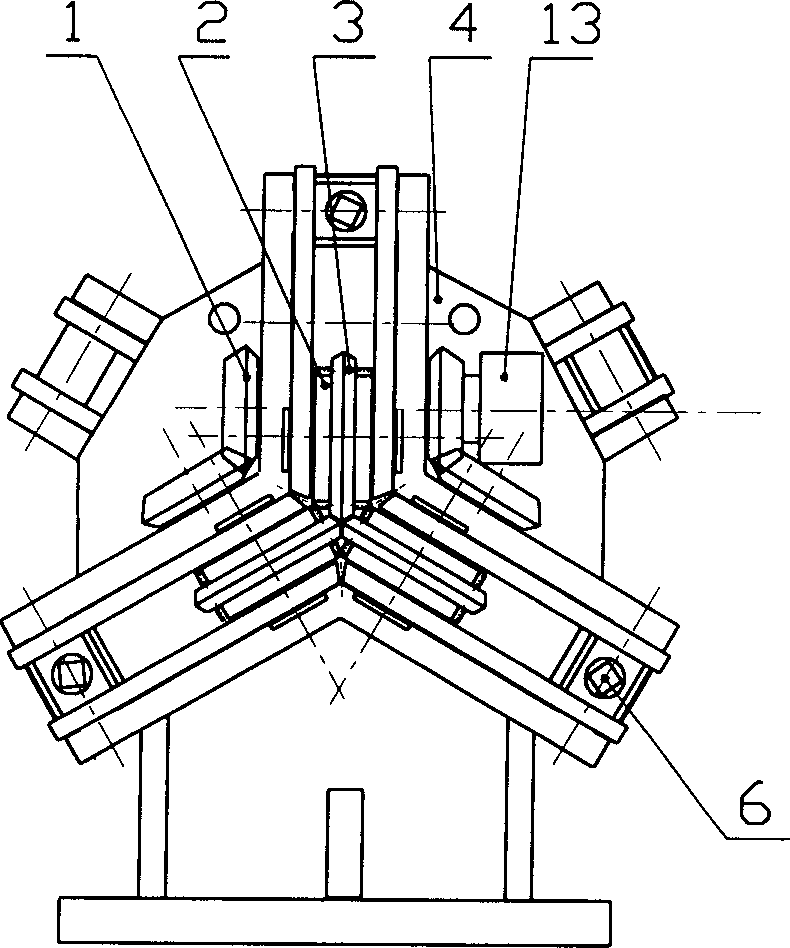

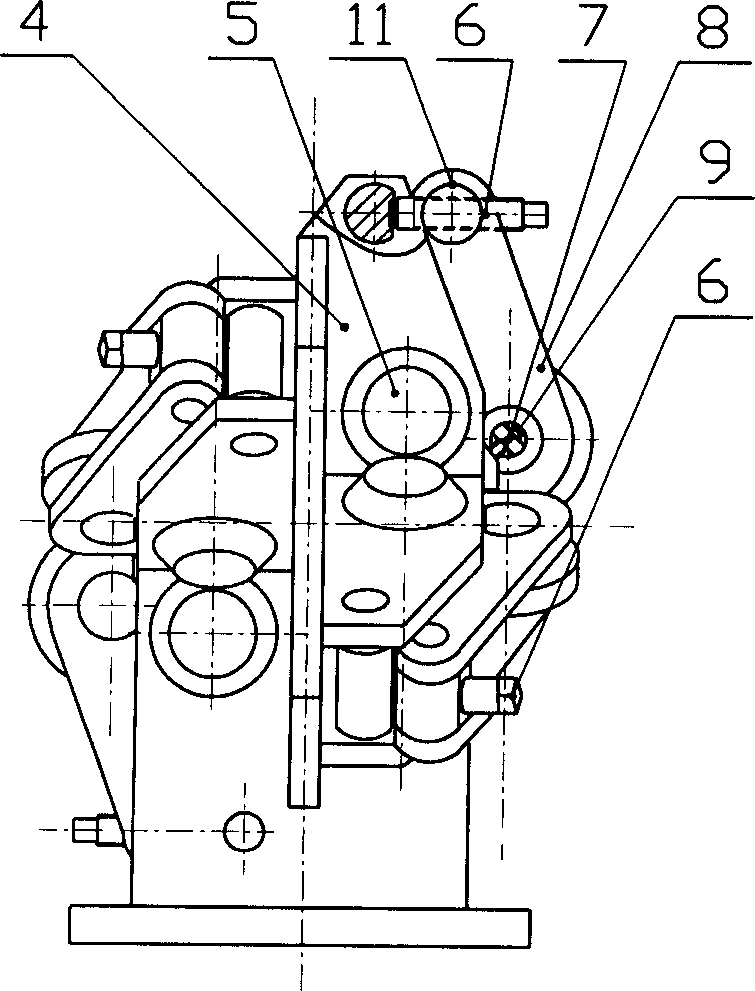

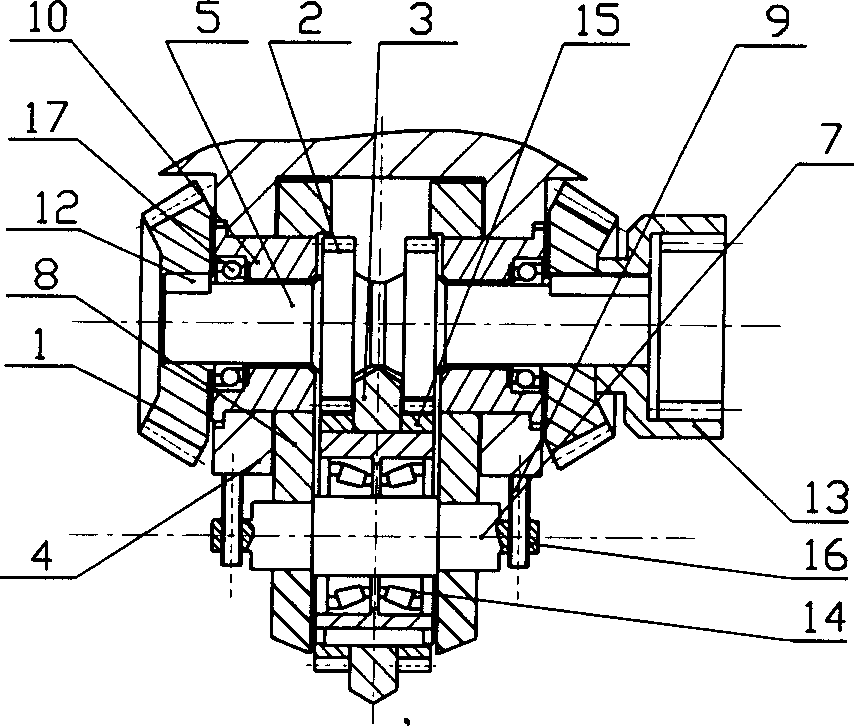

[0023] A three-roll Y-type prestressed rolling mill, such as figure 1 , 2 , 3, 4 shown, on the fixed frame 4, according to the front and rear order, on its left and right sides (see figure 2 (shown) are respectively installed positive Y-type and reverse Y-type two rolling units. The three roll axes and the three transmission axes of each rolling unit are arranged in an equilateral triangle, such as figure 1 shown. Its mechanical transmission system such as image 3 As shown, corresponding to each rolling unit, three groups (two for each group) are fixedly installed in the holes on the fixed frame 4 and have a hollow structure flat shaft 10. The inside of the flat shaft 10 is equipped with a middle shaft through a bearing 17. The transmission shaft 5 of the group cylindrical gear 2, the three transmission shafts 5 of the same rolling unit are equipped with the bevel gear 1 connected with the transmission shaft 5 through the key 12, and there are three groups (two in each g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com