Tortional damper pulley

A technology of pulleys and hubs, applied in belts/chains/gears, springs/shock absorbers, flywheels, etc., can solve the problems of lack of versatility, high cost, expensive equipment, etc., achieve high versatility, reduce processing hours, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

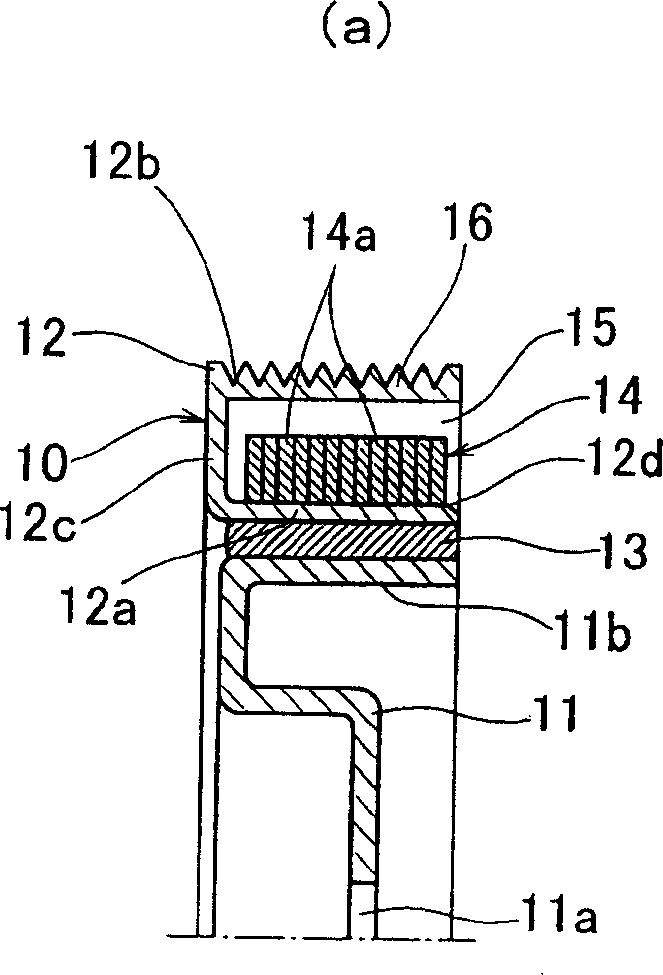

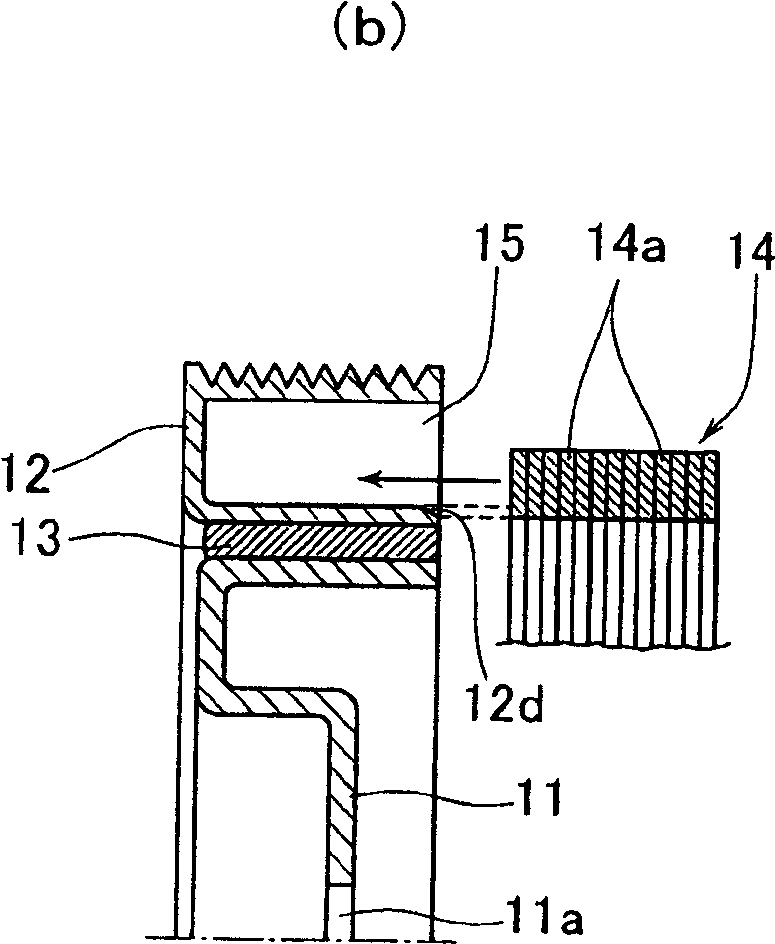

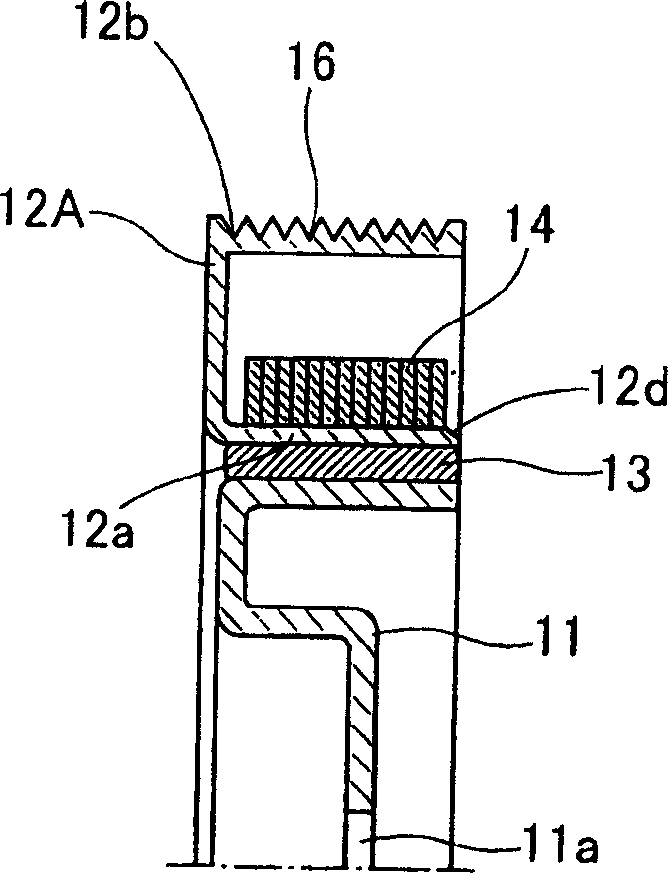

[0029] figure 1 It is a sectional view of a main part showing one embodiment of the torsional vibration damping pulley of the present invention. The torsional vibration damping pulley includes: a hub 11 fixed to the rotating shaft of an internal combustion engine, such as a crankshaft (not shown in the figures) of an automobile engine, via a mounting hole 11a with bolts, and a diameter of an annular fixing portion 11b on the outer periphery of the hub 11 The annular pulley main body 10 and the elastic body 13 interposed between the outer peripheral surface of the annular fixing portion 11 b and the inner peripheral surface of the pulley main body 10 are arranged coaxially outward in the direction.

[0030] The pulley main body 10 includes: an annular frame body 12 having a substantially U-shaped cross section having a recess 15 opening on one side in the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com