Mechanical interlocking mechanism

An interlocking mechanism and mechanical technology, applied in building components, building structures, door/window applications, etc., can solve the problems of inconvenient application of electromagnetic interlocking mechanism and inconvenience of electromagnetic interlocking mechanism application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

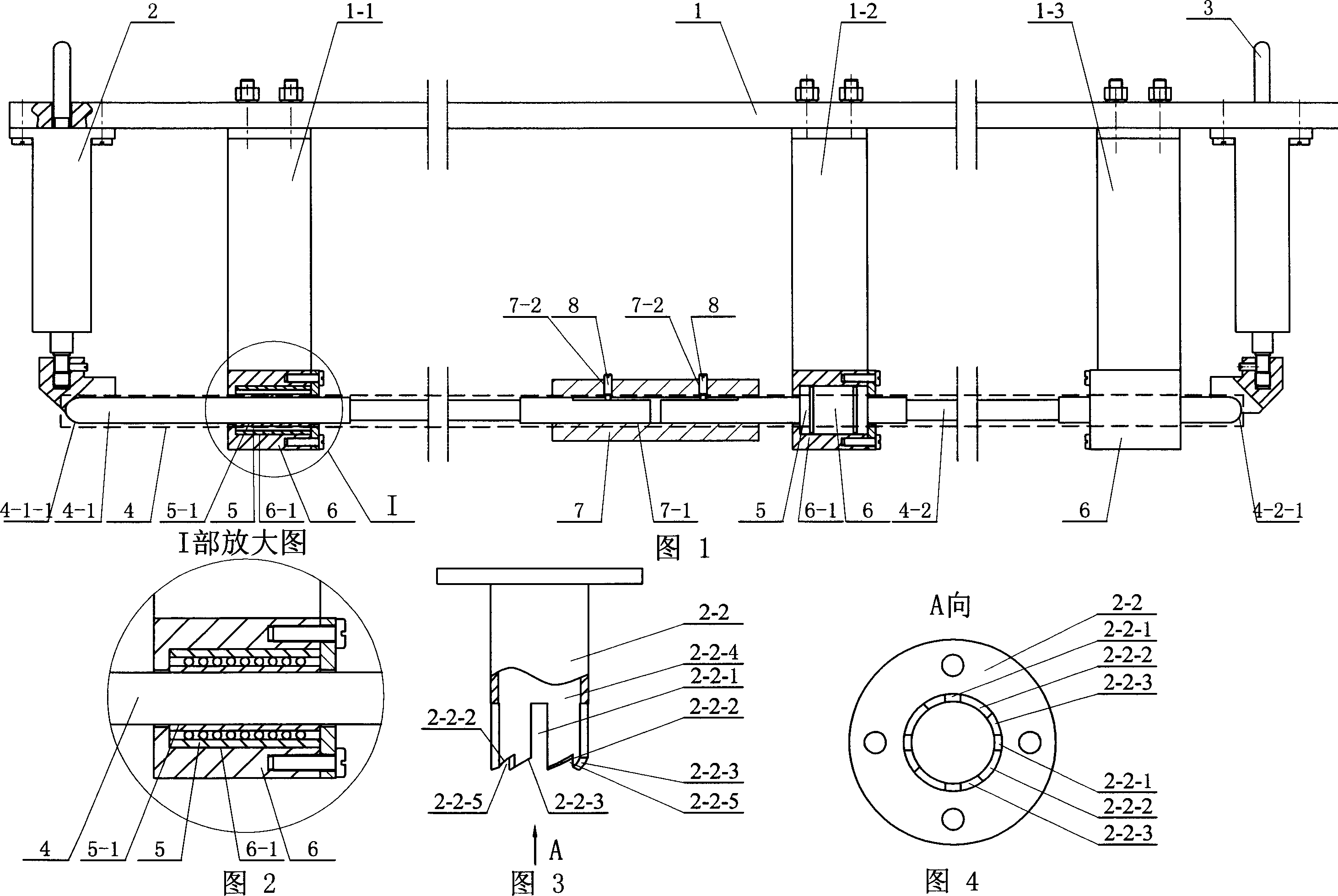

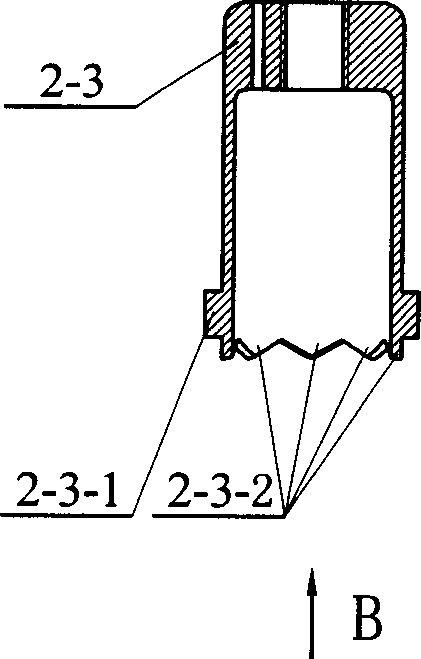

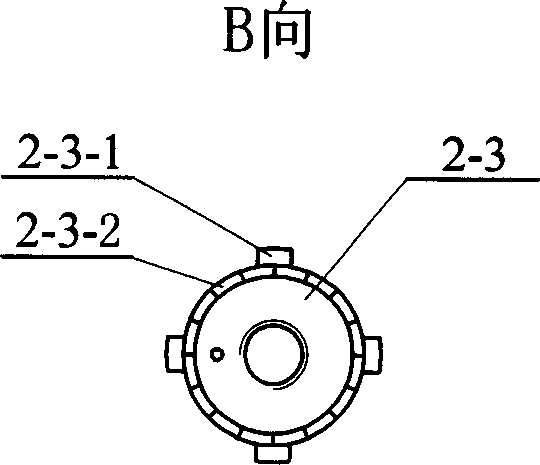

[0005] Specific implementation mode one: (see Fig. 1- Figure 9 ) This embodiment consists of a lock bracket 1, a front lock mechanism 2, a rear lock mechanism 3 and a linkage shaft 4. The rear end is affixed; the middle front part, the middle part and the middle rear part of the lock bracket 1 are respectively fixed with a front bearing bracket 1-1, a middle bearing bracket 1-2 and a rear bearing bracket 1-3, and the front bearing bracket 1-1, The lower ends of the middle bearing bracket 1-2 and the rear bearing bracket 1-3 are respectively fixed with a linear bearing 6, and the three linear bearings 5 are respectively placed in the inner holes 6-1 of the three linear bearings 6; the linkage shaft 4 is placed in the inner hole 5-1 of the cage of the three linear bearings 5, the front end and the rear end of the linkage shaft 4 are respectively in contact with or loosened from the lower end of the front lock mechanism 2 and the lower end of the rear lock mechanism 3; the fro...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see Figure 9 ) The difference between this embodiment and the specific embodiment one is that it increases the top screw 2-11, the lower end of the shaft 2-6 is provided with an external thread 2-6-3, and the upper end surface of the top cone 2-8 has a Connect the threaded hole 2-8-2, the side of the top cone 2-8 has a threaded hole 2-8-3, the lower end of the shaft 2-6 is threaded with the upper end of the top cone 2-8, and the top screw 2-11 is screwed in Inside the threaded hole 2-8-3. Other compositions and connections are the same as in the first embodiment. An advantage of this embodiment is that the axial position of the top cone 2-8 relative to the shaft 2-6 is adjustable, which is convenient for installation and debugging.

specific Embodiment approach 3

[0008] Specific embodiment three: (see Fig. 1) the difference between this embodiment and specific embodiment one and two is that it has increased coupling sleeve 7, two jackscrews 8, and coupling sleeve 7 is provided with axial through hole 7- 1. The front part and the rear part of the side wall of the coupling sleeve 7 are respectively provided with radial threaded holes 7-2, and the two threaded holes 7-2 are respectively connected with the axial through hole 7-1. The shaft 4-1 and the rear section shaft 4-2 are composed, the front end head 4-1-1 of the front section shaft 4-1 is a spherical surface, and the rear end of the front section shaft 4-1 is placed in the front of the axial through hole 7-1, The rear end 4-2-1 of the rear section shaft 4-2 is a spherical surface, and the front end of the rear section shaft 4-2 is placed in the rear portion of the axial through hole 7-1, and two top screws 8 are screwed into two diameters respectively. Into the threaded hole 7-2. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com