Electric heating type cleaning machine

A cleaning machine, electric heating technology, applied in the field of cleaning machines, can solve the problems of limited use, inconvenient movement, open flame heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

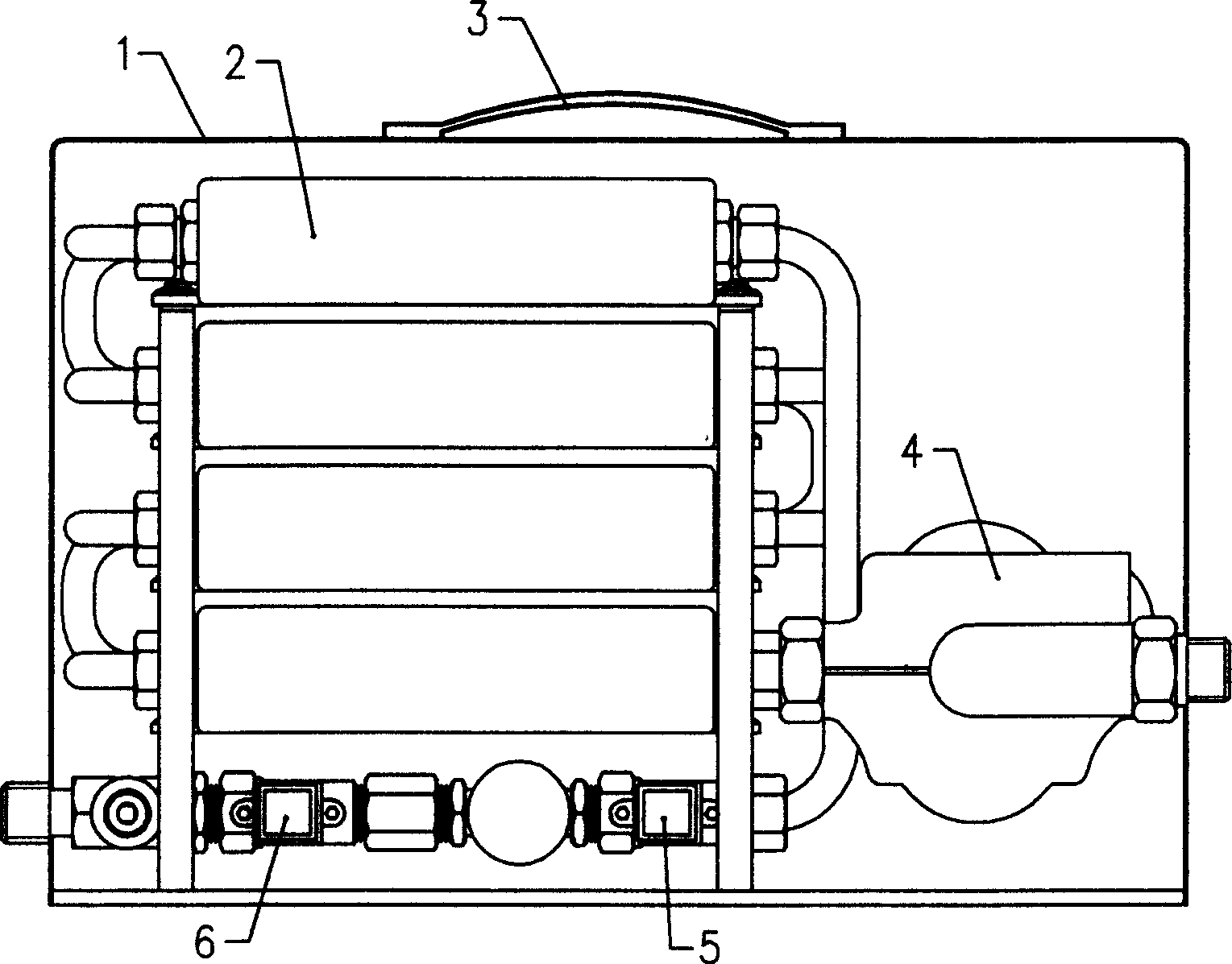

[0015] The first embodiment: as figure 1 As shown in the electric heating type cleaning machine, one end of the water flow channel is connected to the water source, and the other end is connected to the water spray gun. Four electric heaters 2 arranged in parallel are installed in the casing 1 in a liquid-tight manner, and the water inlets and outlets thereof are respectively connected in parallel to form a general water inlet and a general water outlet. According to the size of the water output, the quantity of the electric heating body 2 can be increased or decreased. The outer surface of the electric heating body 2 is provided with an electrothermal film, which includes a nanometer metal-based far-infrared radiation film on the inner layer and a nanometer tin dioxide (antimony) composite conductive film on the outer layer. The infrared radiation film performs far-infrared heating on the water flow flowing through the inner cavity of the electric heating body. The body of ...

no. 2 example

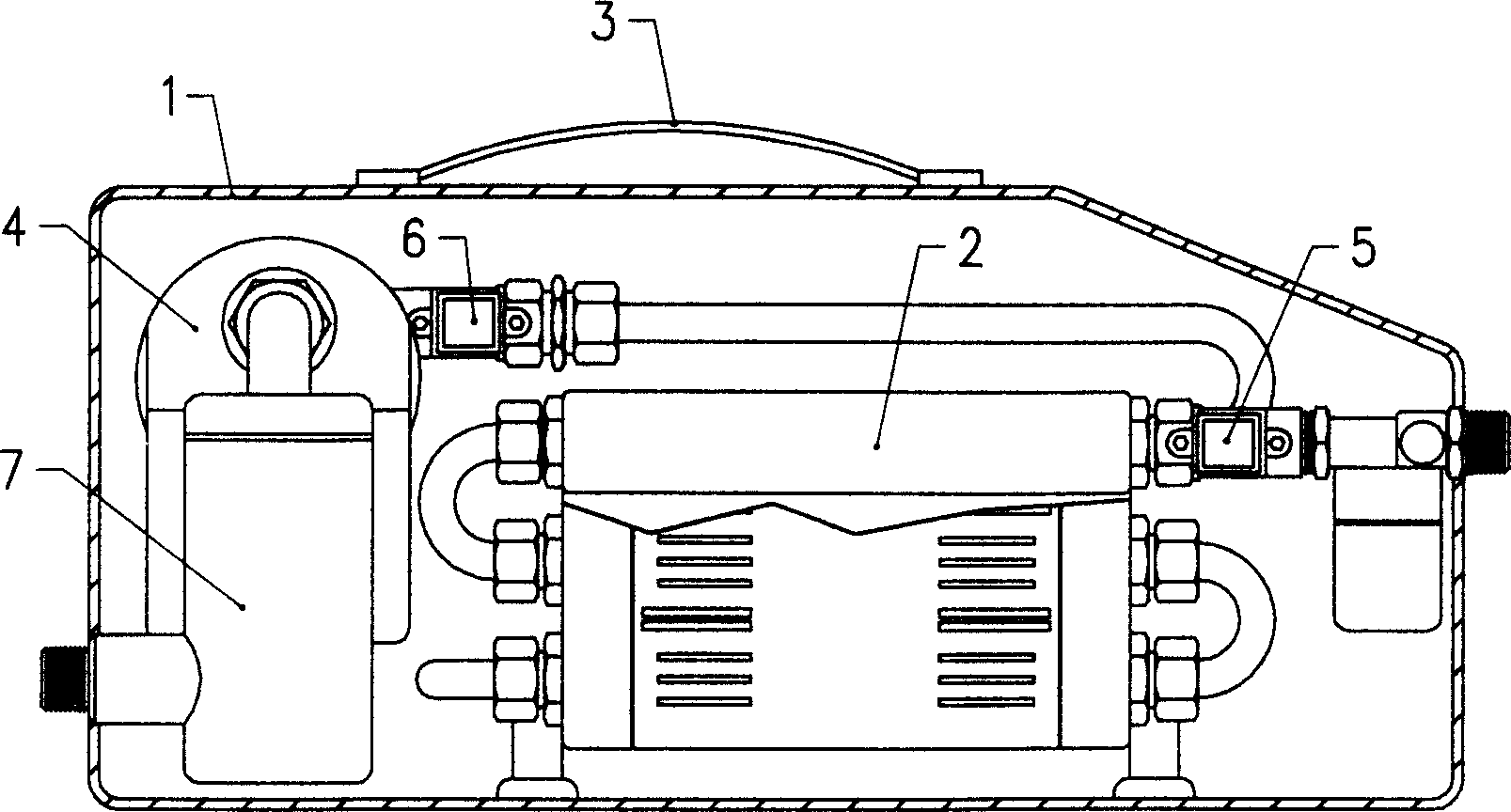

[0017] The second embodiment: as figure 2 As shown, its structure is basically the same as that of the first embodiment, the difference is that the steam generator 7 is connected in series with the water flow path, and the water spray gun handle is provided with a hot water / steam selection switch electrically connected with the electric control device. Setting the steam generator 7 can effectively save the water source. The bottom of the casing 1 is provided with a fixing hole for wall hanging installation. It weighs about 7Kg and is equipped with a power of 3-12Kw. It is especially suitable for use in low-temperature conditions such as car washes, drilling rigs, well sites, etc. where the movement is not large or wall-mounted installation is required.

no. 3 example

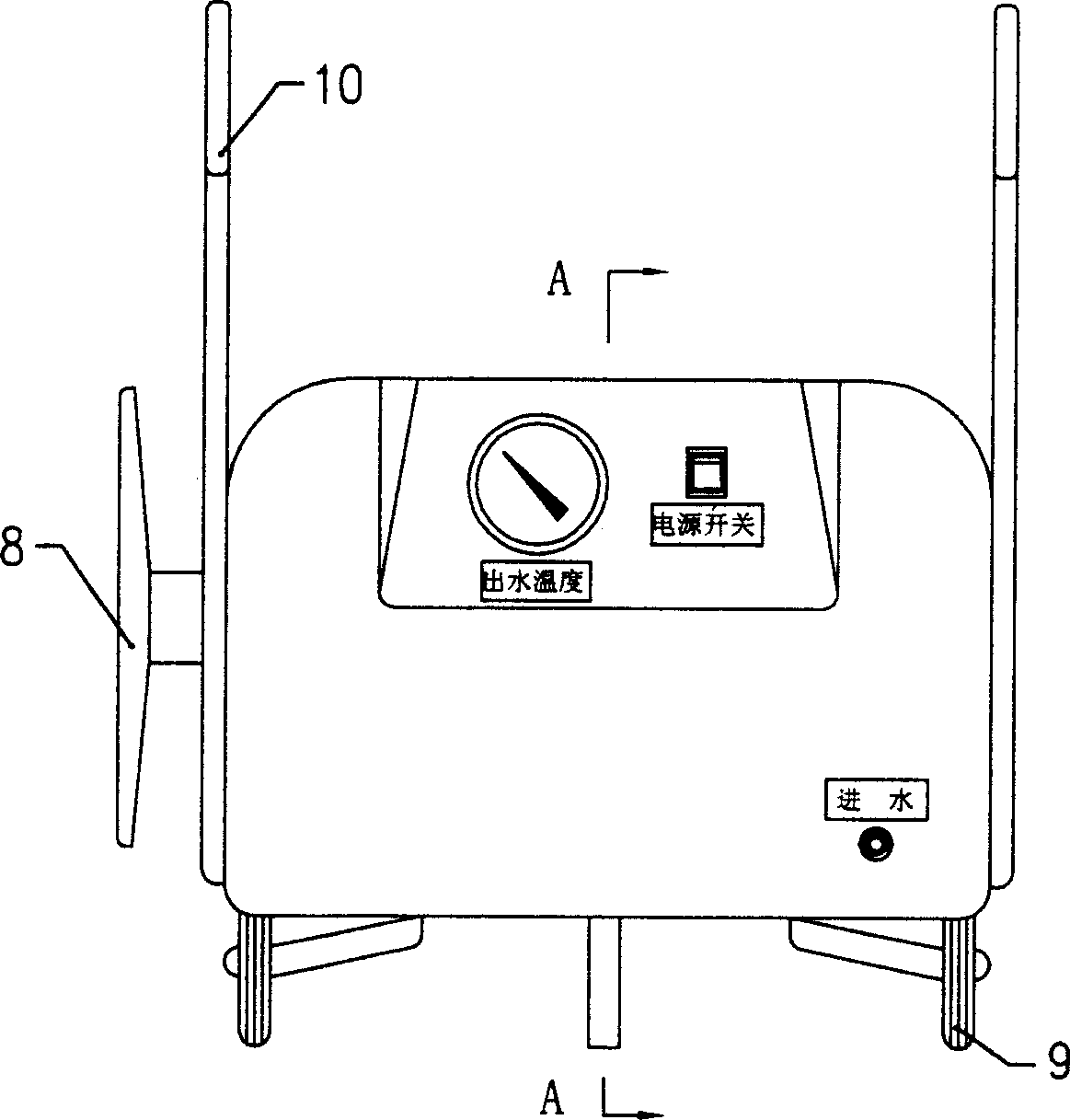

[0018] The third embodiment: as image 3 and Figure 4 As shown, its structure is basically the same as that of the second embodiment, the difference is that there are ten electric heating bodies 2, and a push handrail 10 is installed on the upper part of the casing 1, and a wrapping cable that can be retracted is installed on its side. Disc 8, road wheel 9 is installed at its bottom. The weight is about 15Kg, equipped with hot water heating power of 10-30Kw, especially suitable for trains, tanks, airplanes, ships, large vehicles and other mobile devices under low temperature conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com