Electric dust collector

A vacuum cleaner and electric technology, applied in the installation of vacuum cleaners, suction hoses, electrical equipment, etc., can solve the problems of requiring more labor, incapable of common use, cumbersome management of productivity and inventory, etc., to improve operability, The effect of improving productivity and improving inventory management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

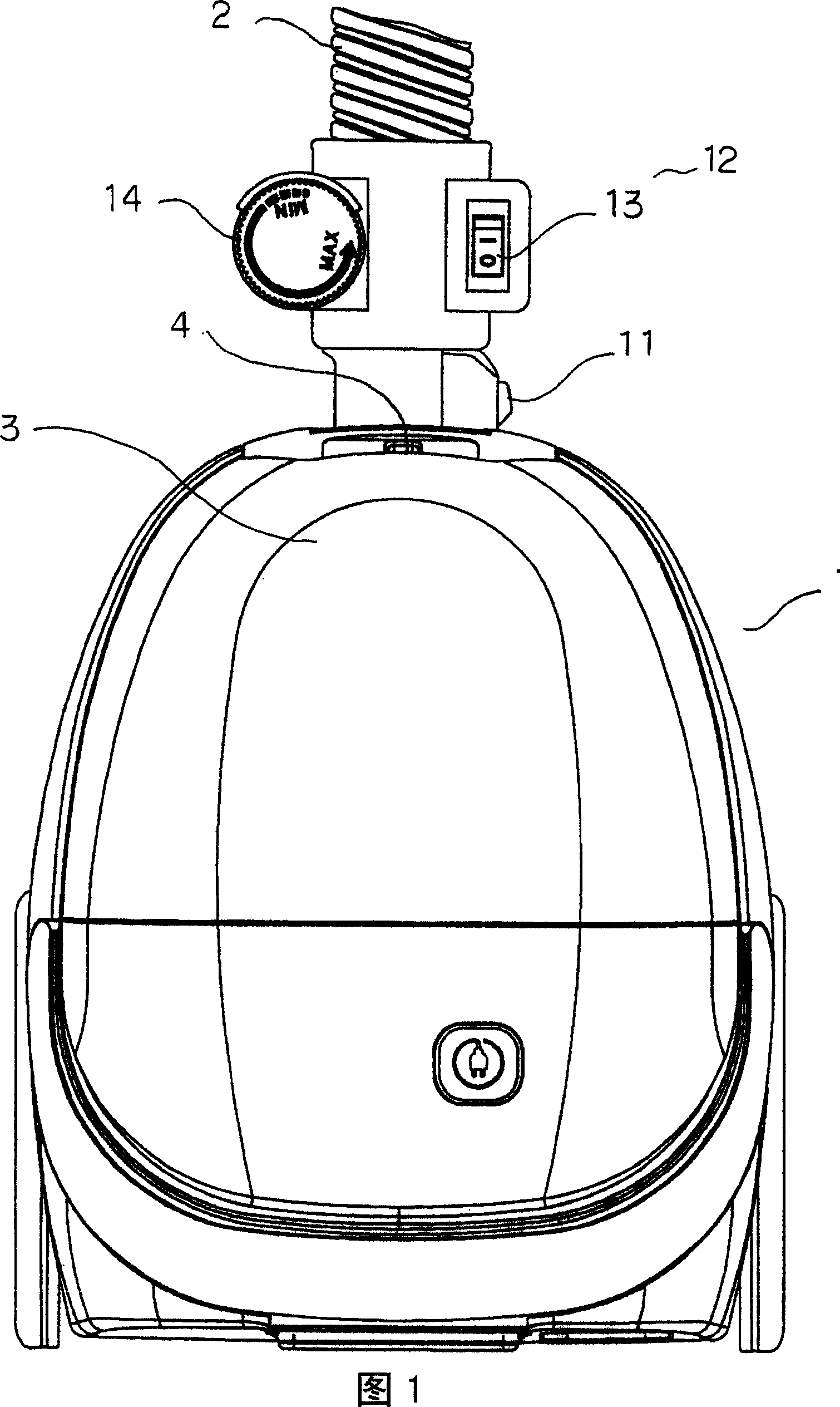

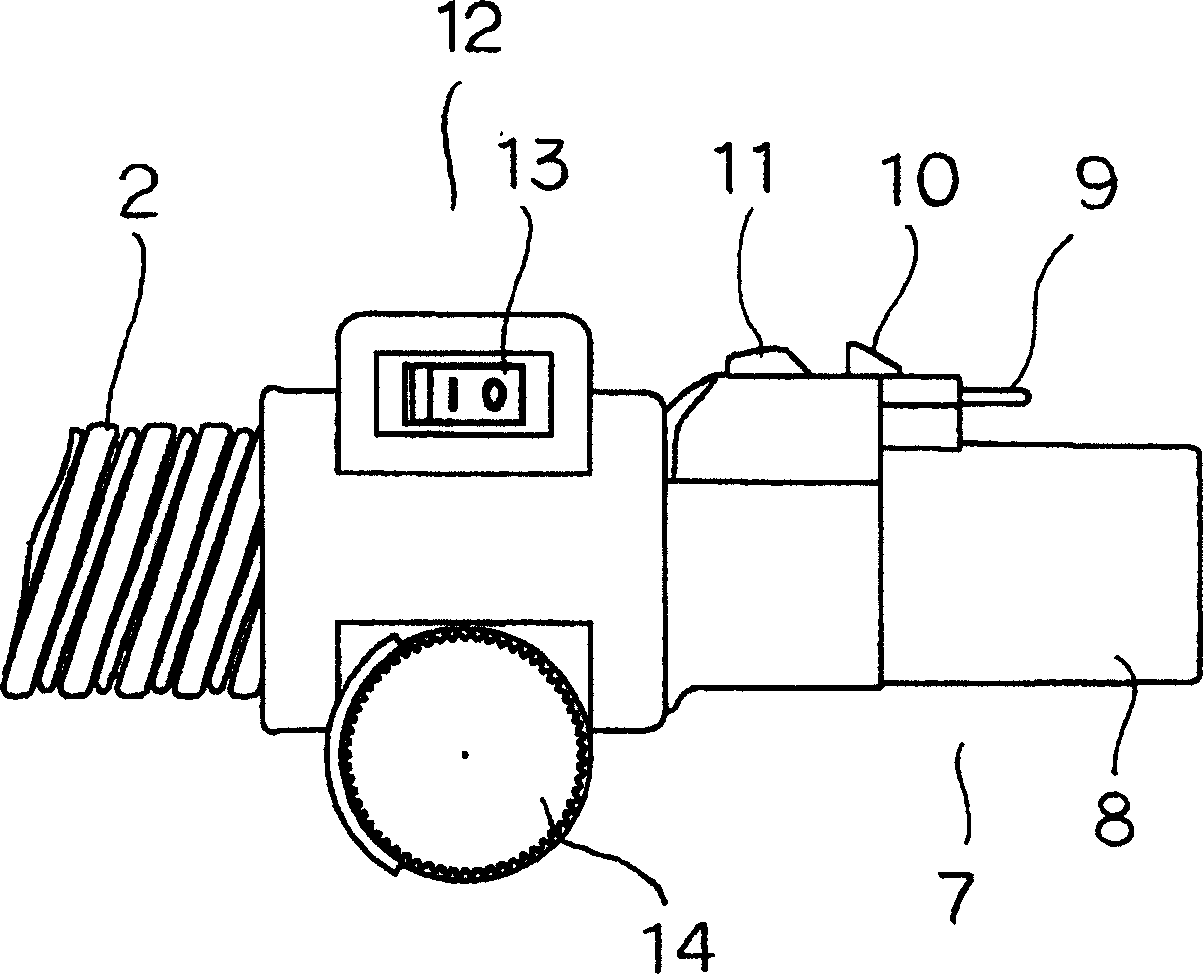

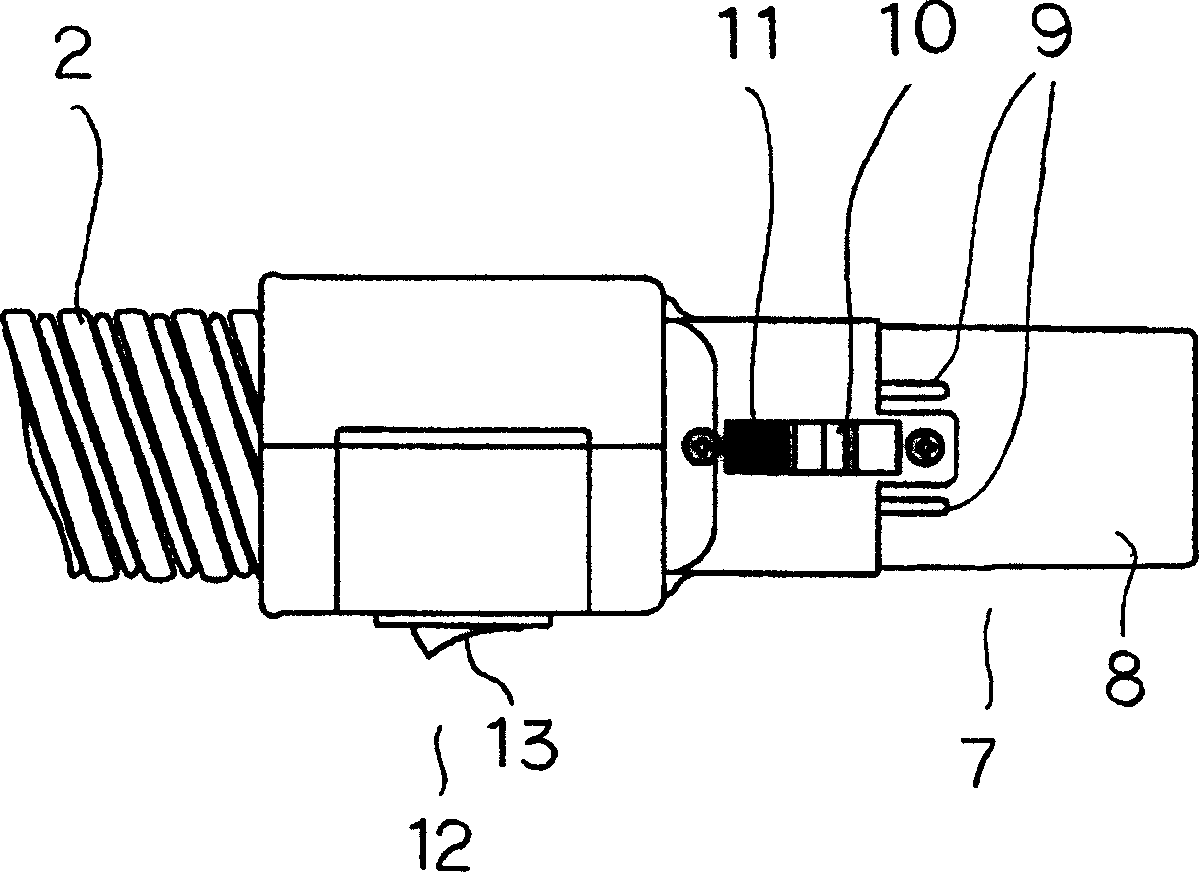

[0091] (first embodiment)

[0092] According to Figure 1~ Figure 6 A first embodiment of the electric vacuum cleaner of the present invention will be described.

[0093] The electric vacuum cleaner according to the first embodiment is composed of a vacuum cleaner body 1 including a dust collecting part and an electric blower not shown in the figure, and a hose 2 detachably attached to the vacuum cleaner body 1 at one end (see FIG. 1 ). The other end side of the hose 2 communicates with the floor suction head via a pipe not shown in the figure. That is, the electric vacuum cleaner of the first embodiment is a canister type electric vacuum cleaner.

[0094] On the front upper surface of the vacuum cleaner body 1, a dust cover 3 that can open and close the dust collecting part is disposed. The dustproof cover 3 can lift the front surface of the dustproof cover 3 upwards by inserting the hand into the switch part 4 formed in the front center of the vacuum cleaner body 1 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com