Internal combustion engine of disrotatory rotor

An internal combustion engine and engine technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of mechanical parts operation and sealing influence, large temperature rise and mechanical wear, low power output value, etc., to achieve cost Reduce and overcome the bottle diameter of output power and the effect of continuous and stable power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in combination with specific embodiments.

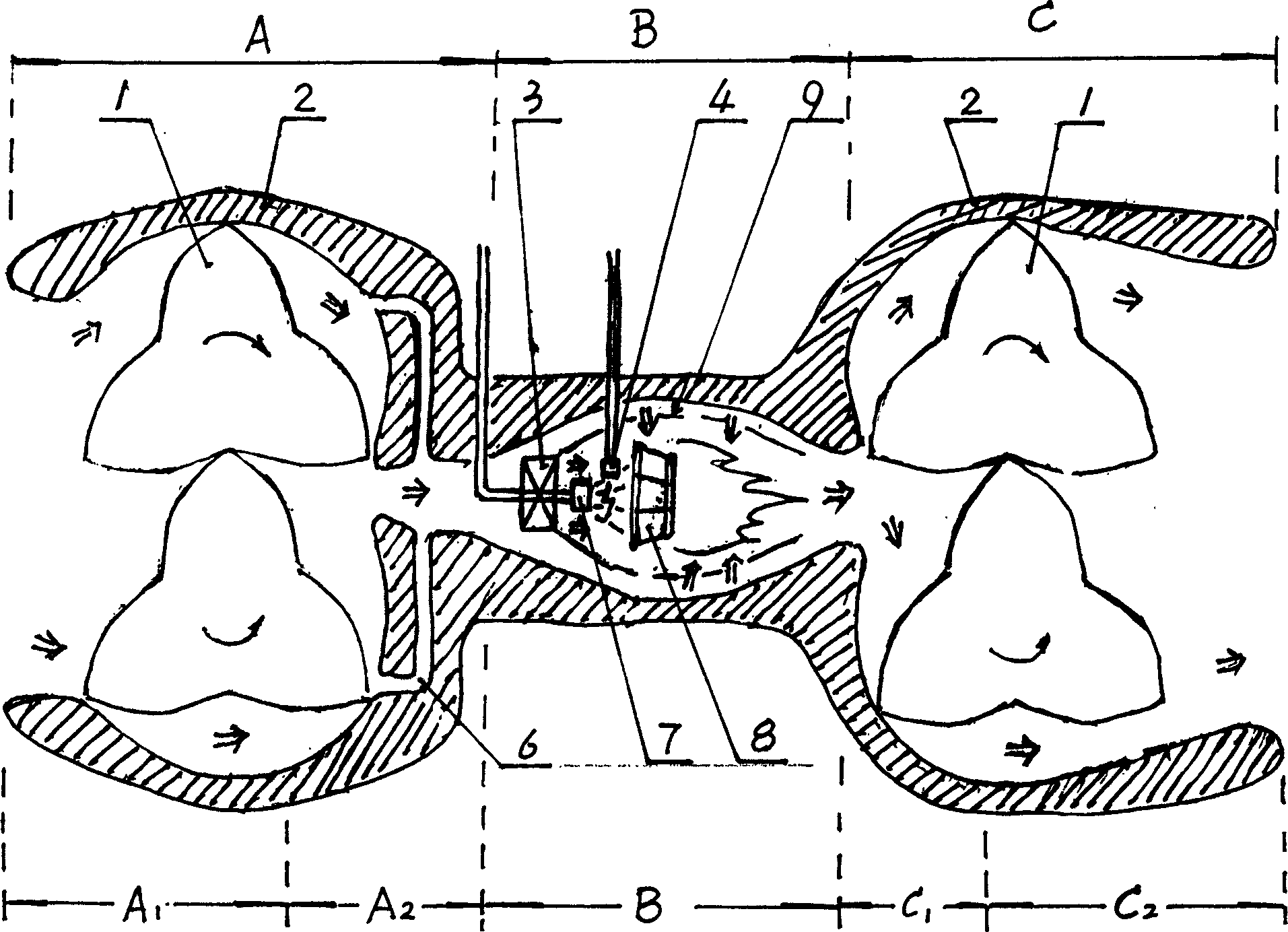

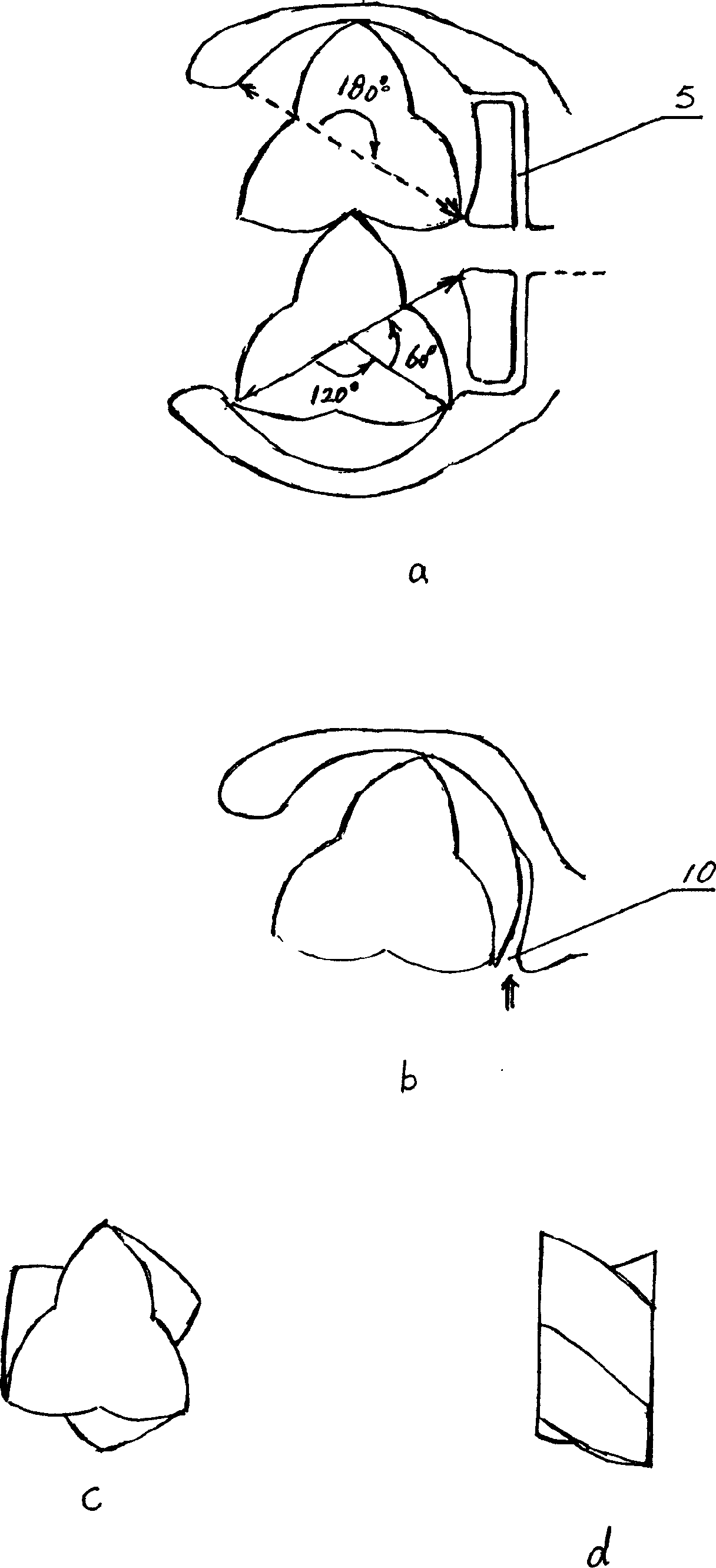

[0021] Such as figure 1 As shown, A is the supercharger, B is the combustion chamber, and C is the expander. A pair of relatively rotating cylindrical rotors 1 are respectively installed in the supercharger and the expander. The cross-sectional shape of the rotor is a three-petal flower shape uniformly distributed within 360° as shown in the figure, and its outer contour adopts a Non-linear involute function curve, the design requires that the radius of curvature of the top of the petal-shaped rotor is smaller than the radius of curvature of the inner wall of the housing. continuity. The front section of the supercharger housing is the suction area A 1 , the rear section is the booster zone A 2 , the pressurized area is provided with a pressure buffer device 6, and its specific structure is as follows figure 2 The channel structure shown in a, that is, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com