Electromagnetic rotary piston pump and multistage electromagnetic rotary piston pump

A piston pump and electromagnetic technology, applied in the field of electromagnetic rotary piston pump, can solve problems such as pressure discontinuity, and achieve the effects of reducing kinetic energy loss, reducing operating costs, and increasing gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

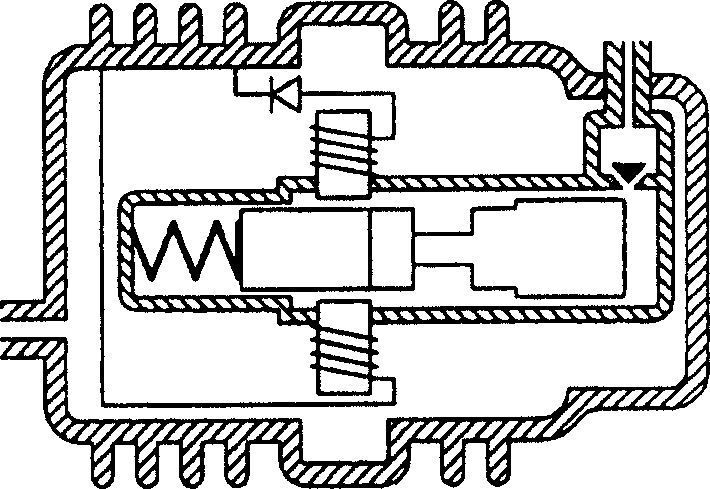

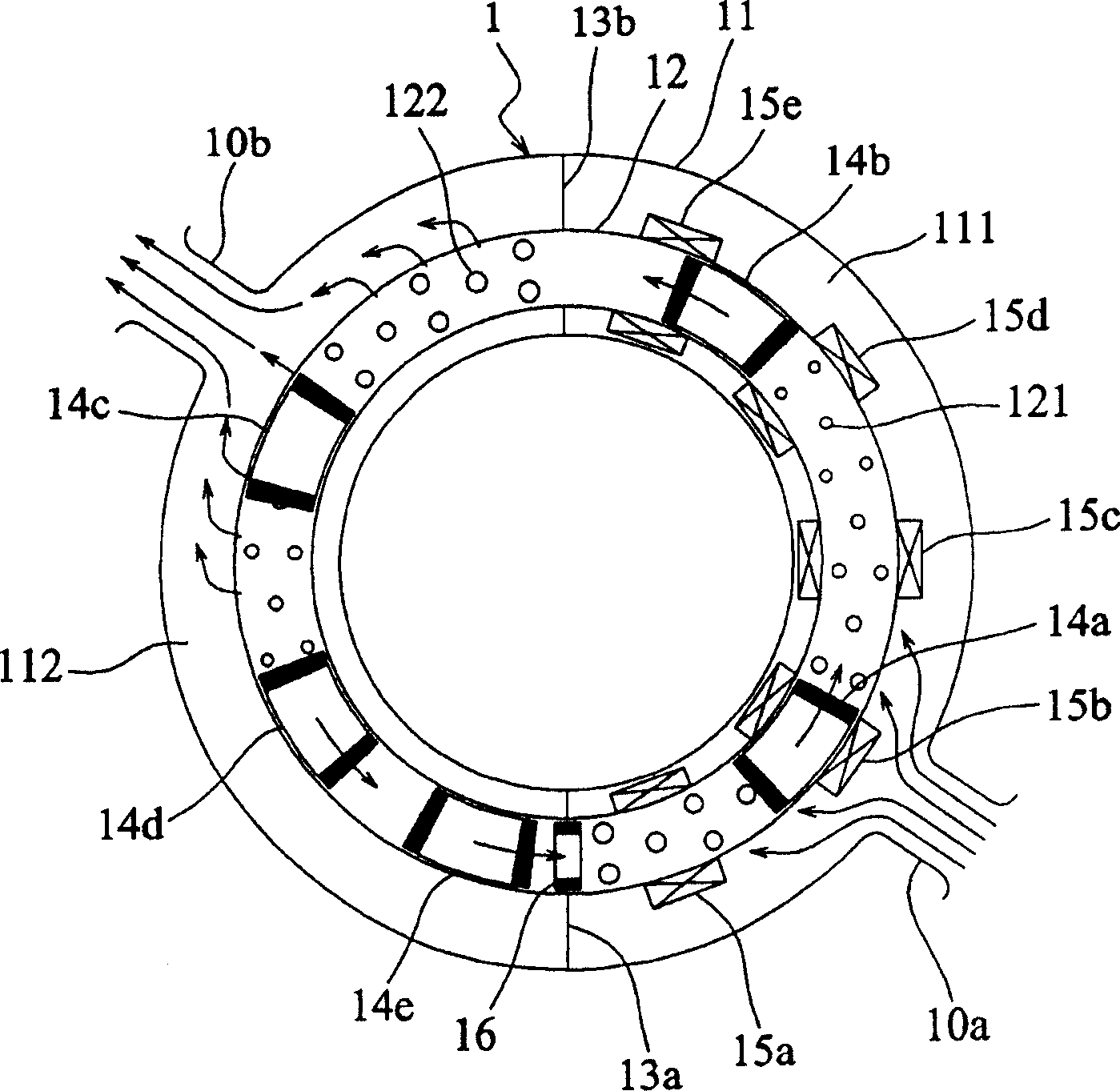

[0023] The electromagnetic rotary piston pump proposed by the present invention uses the electromagnetic force of an external electromagnetic coil to accelerate the piston in an annular (doughnut-shaped) tube with a through hole and rotate continuously to compress the gas.

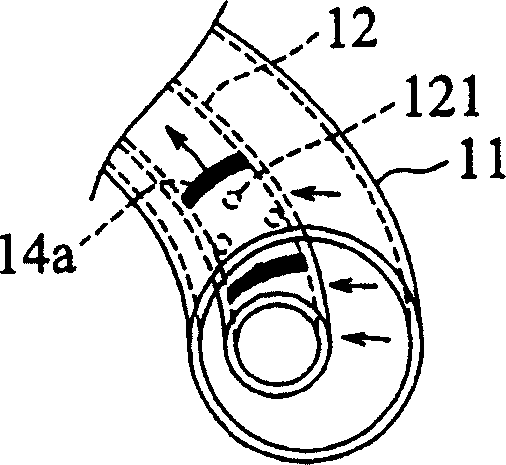

[0024] See Figure 2A and Figure 2B , in the first embodiment, the electromagnetic rotary piston pump 1 of the present invention comprises an outer annular pipe 11 of a plastic material, an inner annular pipe 12 of a brass material, two annular partition plates 13a and 13b, and five pistons 14a to 14e and five sets of electromagnetic coils 15a to 15e.

[0025] In detail, the inner annular pipe 12 is wrapped by the outer annular pipe 11, and a plurality of through holes 121 and 122 are distributed on the wall surface, and two annular partition plates 13a and 13b are placed inside the outer annular pipe 11. The outside of the annular pipe 12 divides the interior of the outer annular pipe 11 into two airti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com