Apparatus for cooling EGR gas

A technology of gas cooling and gas cooler, which is applied in the direction of mechanical equipment, heat exchange equipment, lighting and heating equipment, etc., and can solve the problem that the actuator cannot work smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

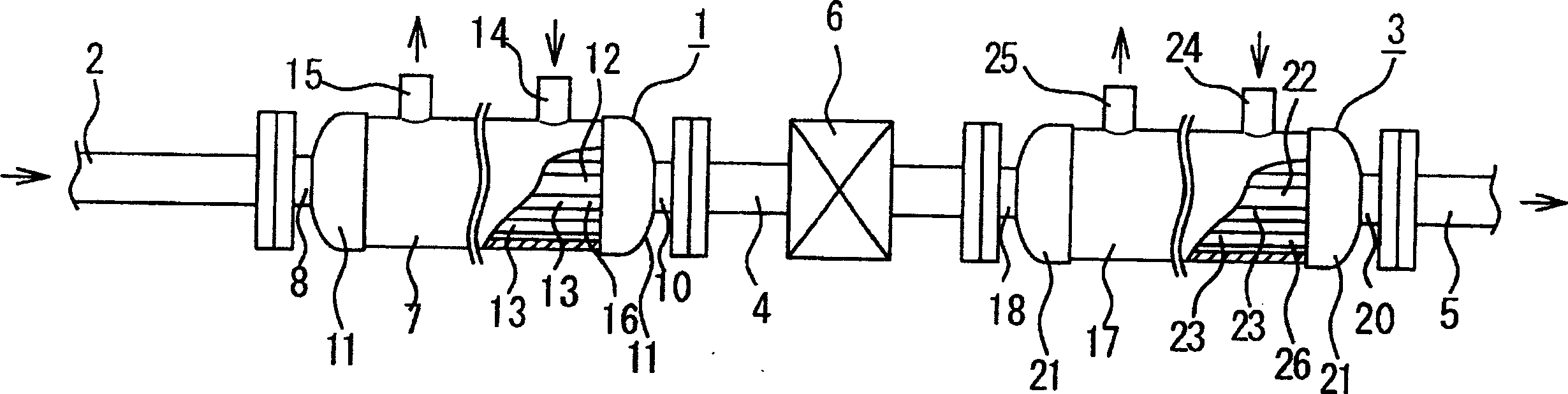

[0030] Refer below figure 1Embodiment 1 in which the EGR gas cooling equipment of the present invention is applied to automobiles is described. A pre-EGR gas cooler 1 is connected to one end of an introduction pipe 2 in which a connecting hole (not shown) of an EGR pipe at the exhaust gas manifold end is installed to perform a first cooling step by introducing high-temperature EGR gas. The medium-temperature EGR gas cooled in the front EGR gas cooler 1 is introduced into the rear EGR gas cooler 3 to cool to the required temperature, and the rear EGR gas cooler 3 is connected in series to the front through the second gas supply pipe 4 One end of the EGR gas cooler. The rear EGR gas cooler 3 is connected to the outlet pipe 5, which is connected to the intake manifold and passes at the other end thereof, so that it can send the low-temperature EGR gas cooled to the required temperature to the intake manifold.

[0031] The EGR valve 6 is installed on the gas supply pipe 4 betwee...

Embodiment 2

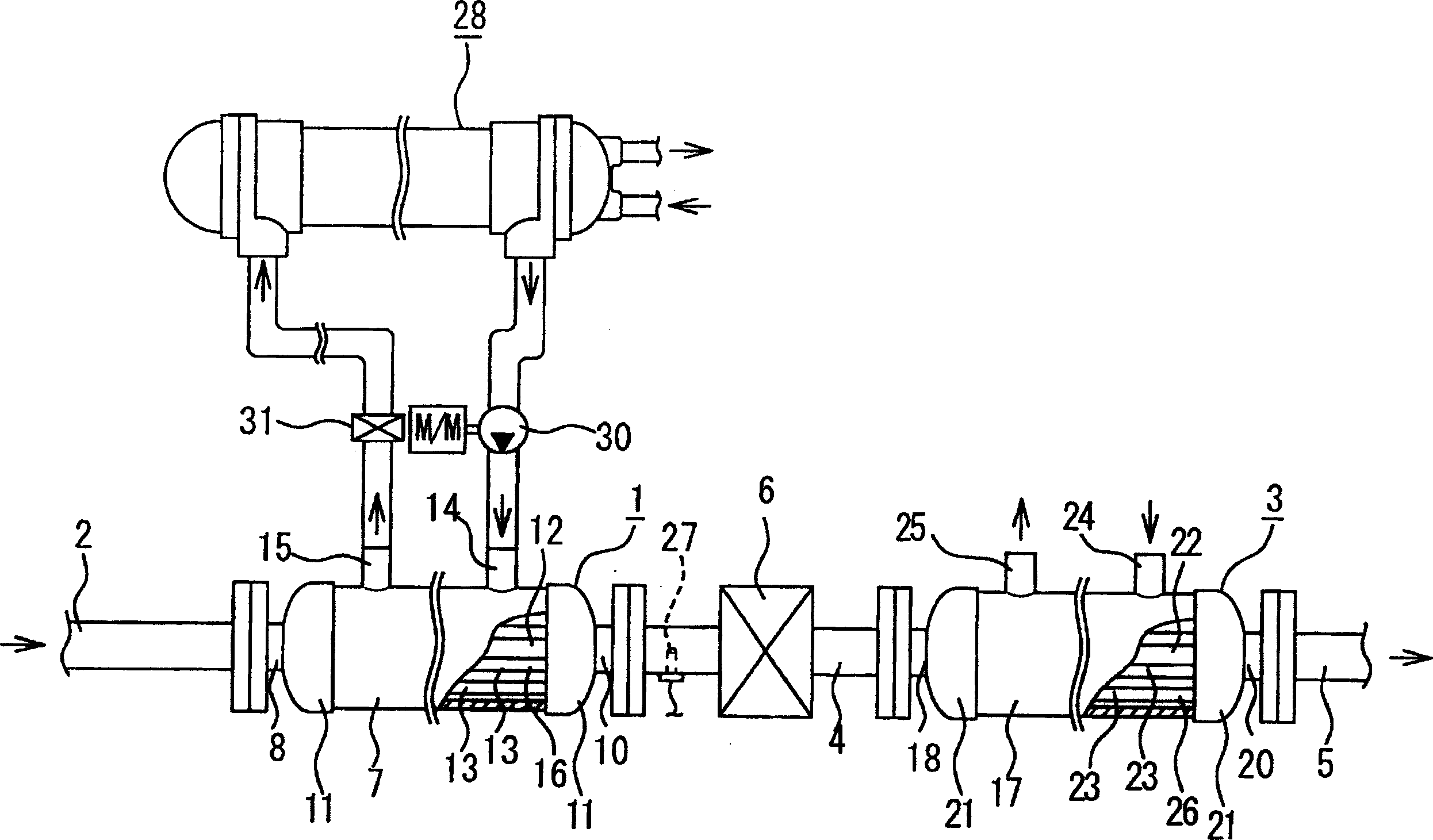

[0048] exist figure 2 In the shown second embodiment, the same as the first embodiment, the front EGR gas cooler 1 is connected in series with the rear EGR gas cooler 3, and the EGR valve 6 is installed in the second supply chain connected to the coolers 1 and 3. On the air pipe 4, the amount of EGR gas introduced into the EGR gas cooling device can be adjusted. Furthermore, in the second embodiment, the temperature sensor 27 is installed between the pre-EGR gas cooler 1 and the EGR valve 6 . The temperature sensor measures the temperature of the medium-temperature EGR gas cooled by the pre-EGR cooler, and monitors the temperature so as to maintain it at 150°C to 200°C.

[0049] In addition, since the high-temperature EGR gas of 150°C or higher is introduced into the pre-EGR gas cooler 1, a high-boiling heat medium fluid, such as a fluorine inert solvent with a boiling point of 150°C or higher, is used so that the cooling liquid is not in the heat. The exchange section 12 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com