Damper and door handle having the same

A technology for dampers and door handles, applied in the field of dampers and door handles, can solve the problem of torque reduction and achieve the effect of torque reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Next, a damper according to an embodiment of the present invention will be described.

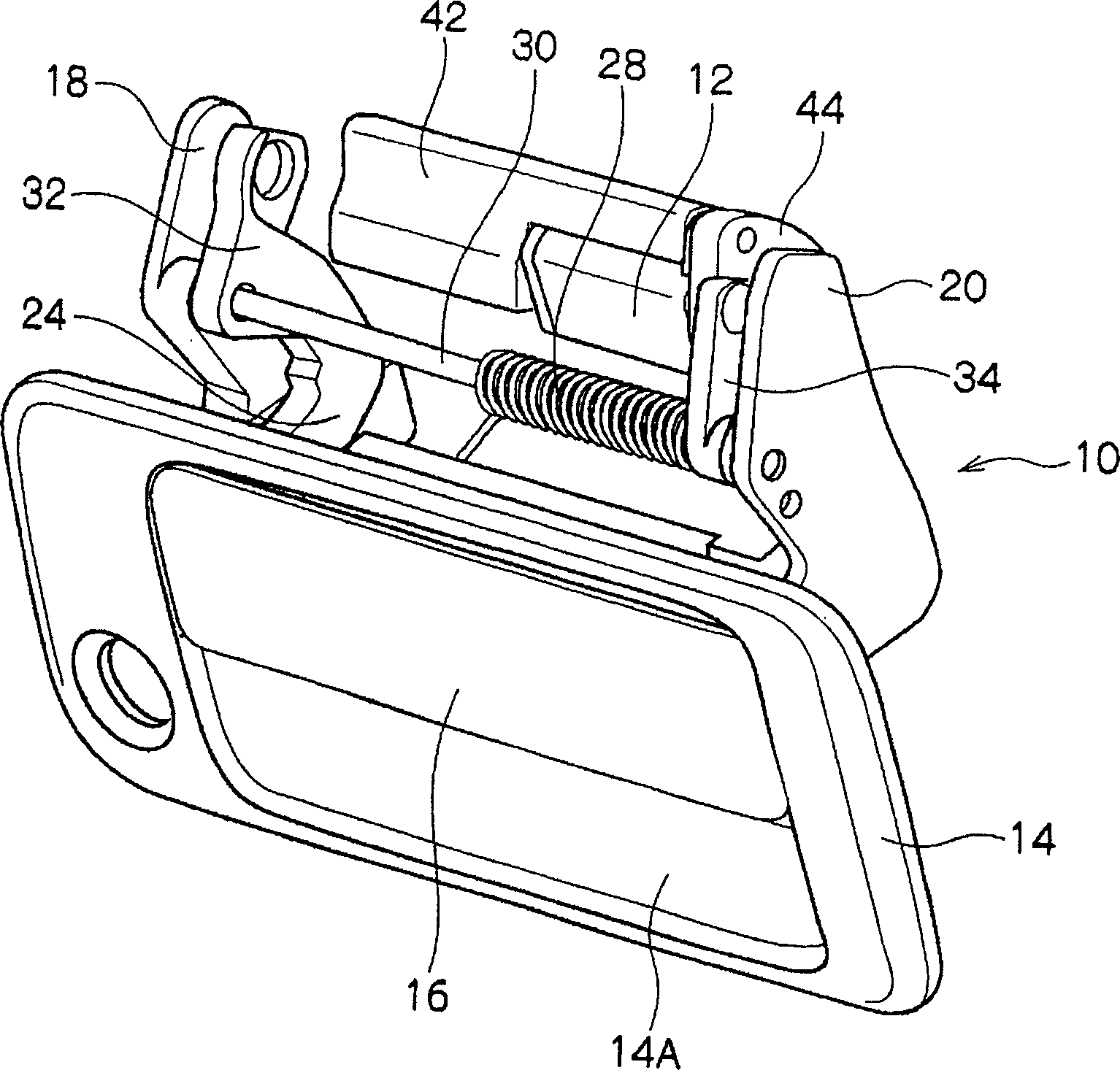

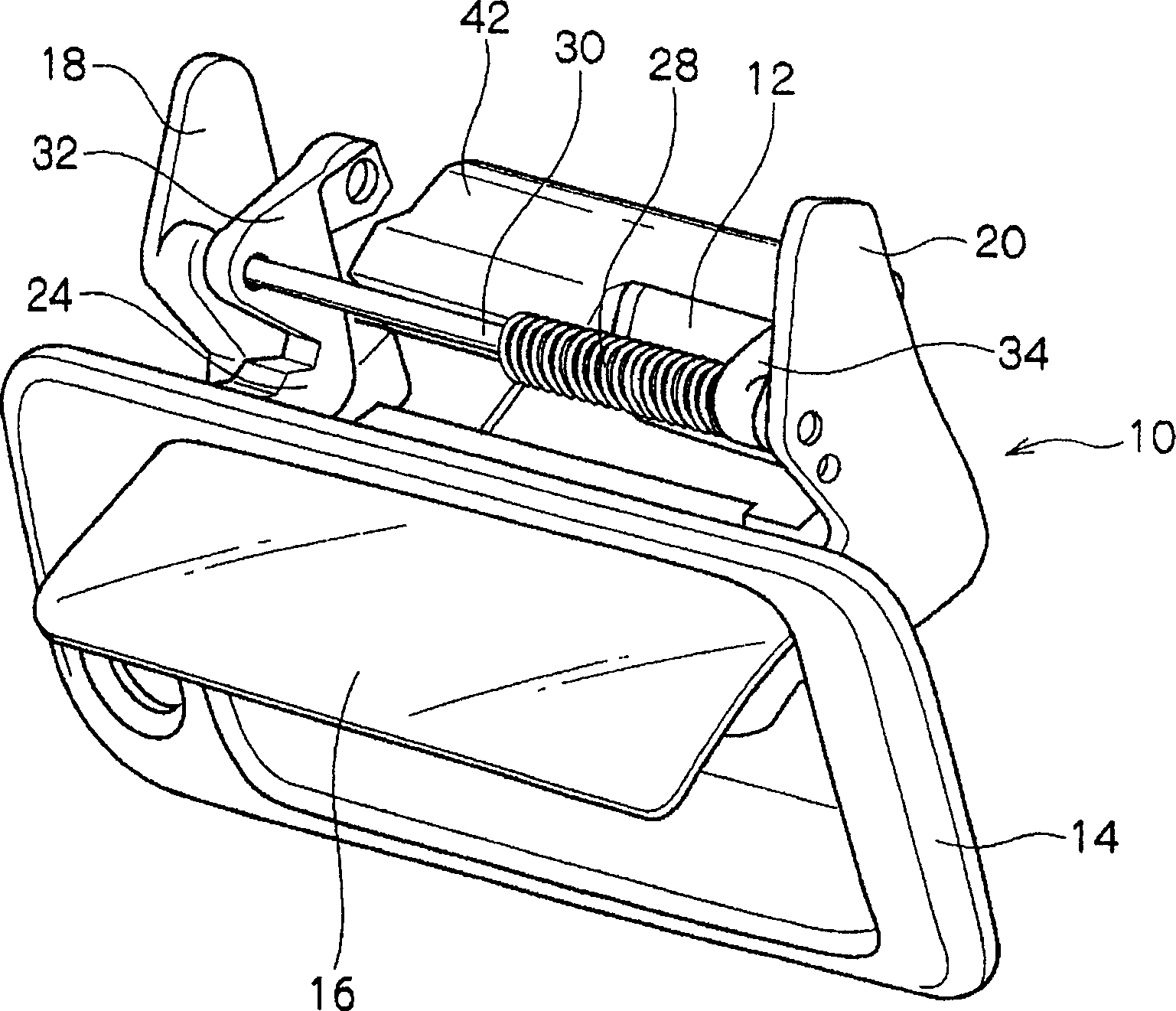

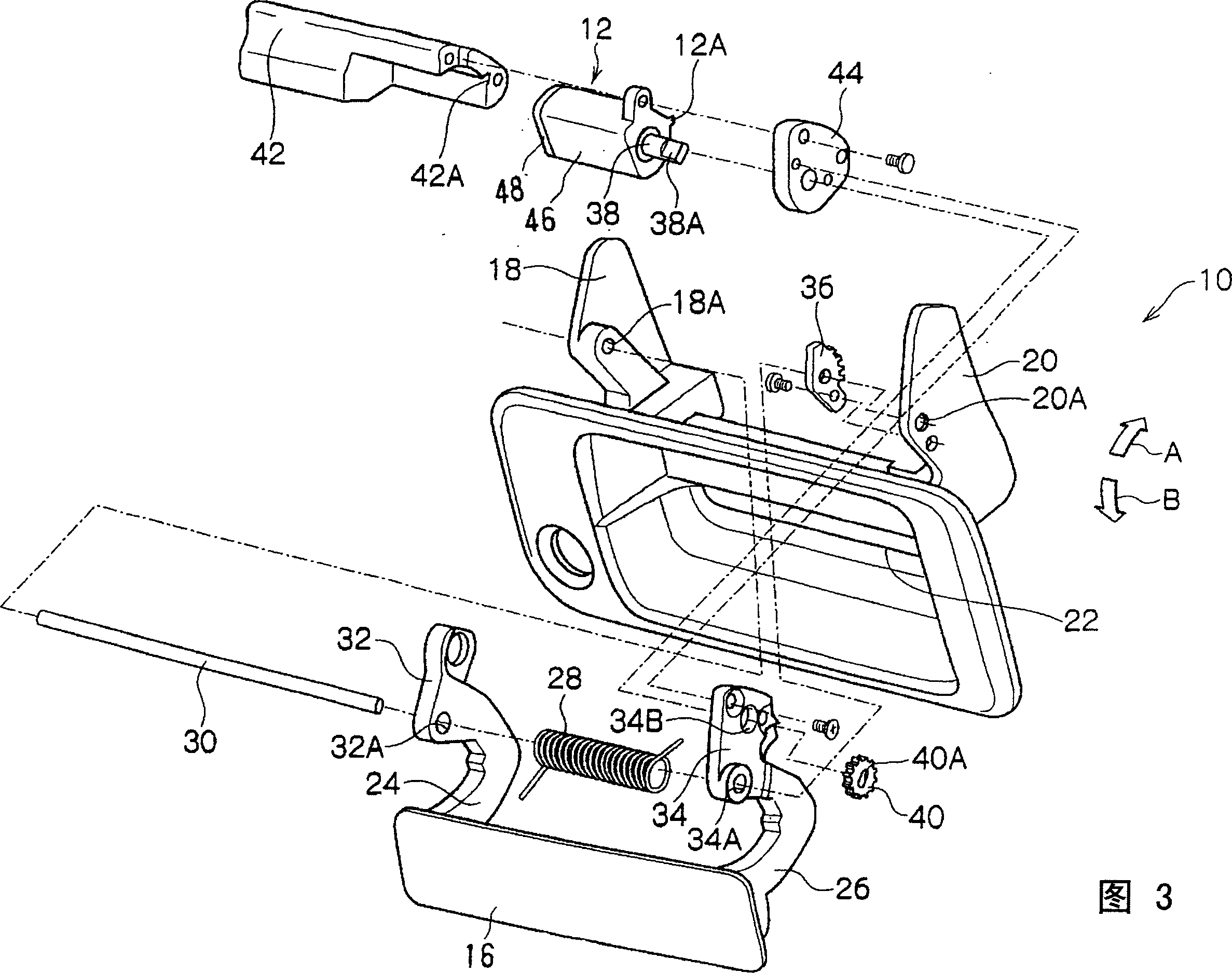

[0067] Such as figure 1 ~Shown in 3, on the car door (not shown in the figure) of automobile, be provided with the door handle 10 that switch car door is useful, on this door handle 10, have used the damper 12 of present embodiment.

[0068] The door handle 10 can be roughly divided into two parts: a main body 14 and an operating handle 16 , the main body 14 is fixed on one side of the vehicle panel, and the operating handle 16 can rotate relative to the main body 14 .

[0069] A pair of mounting plates 18, 20 project from the inner surface of the body portion 14 and are secured to a vehicle panel (not shown). In addition, on the surface of the main body portion 14, there is provided a concave portion 14A which is recessed and can accommodate the handle 16 for operation, and an opening portion 22 is formed on the concave portion 14A. 24, 26 can pass through this opening part.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com