Composite double filement master-slave style three filament and three spiral filement and manufacture thereof

A manufacturing method and double-auxiliary helix technology, applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problems of low service life of fluorescent lamps, improve electrothermal conversion efficiency, firm adhesion, shorten pre-heating, etc. The effect of heat time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

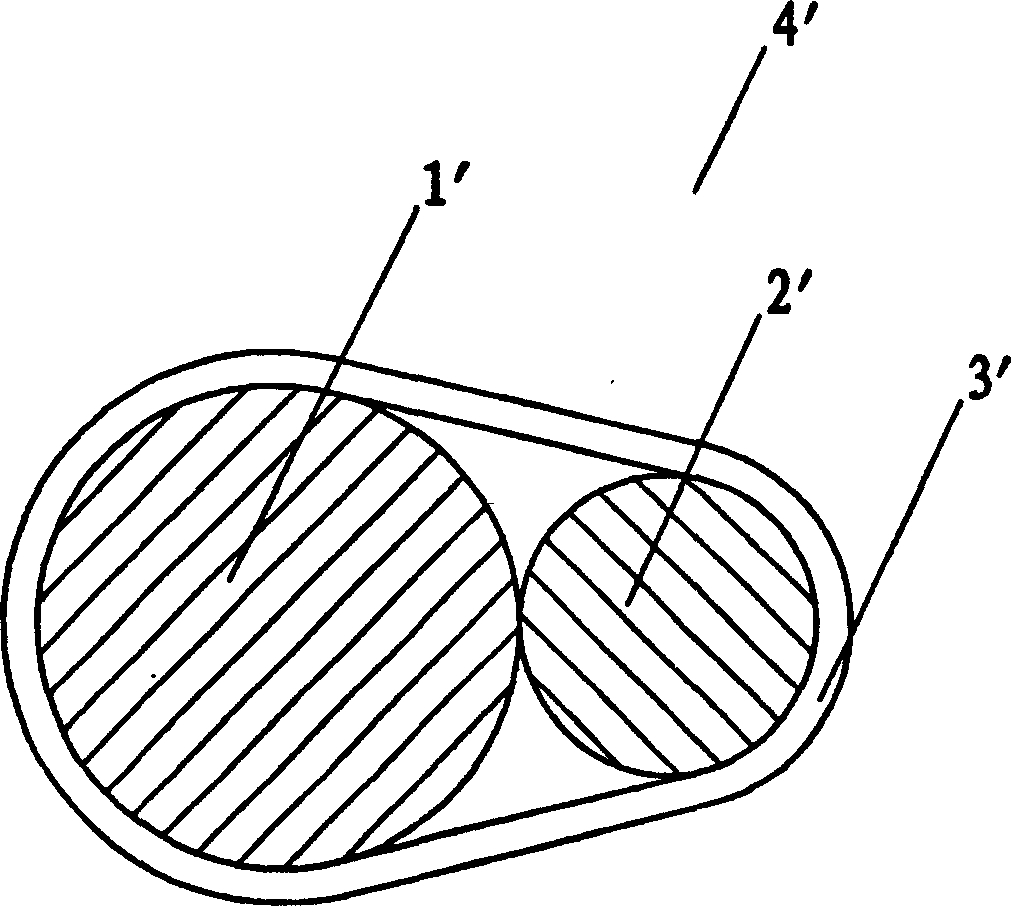

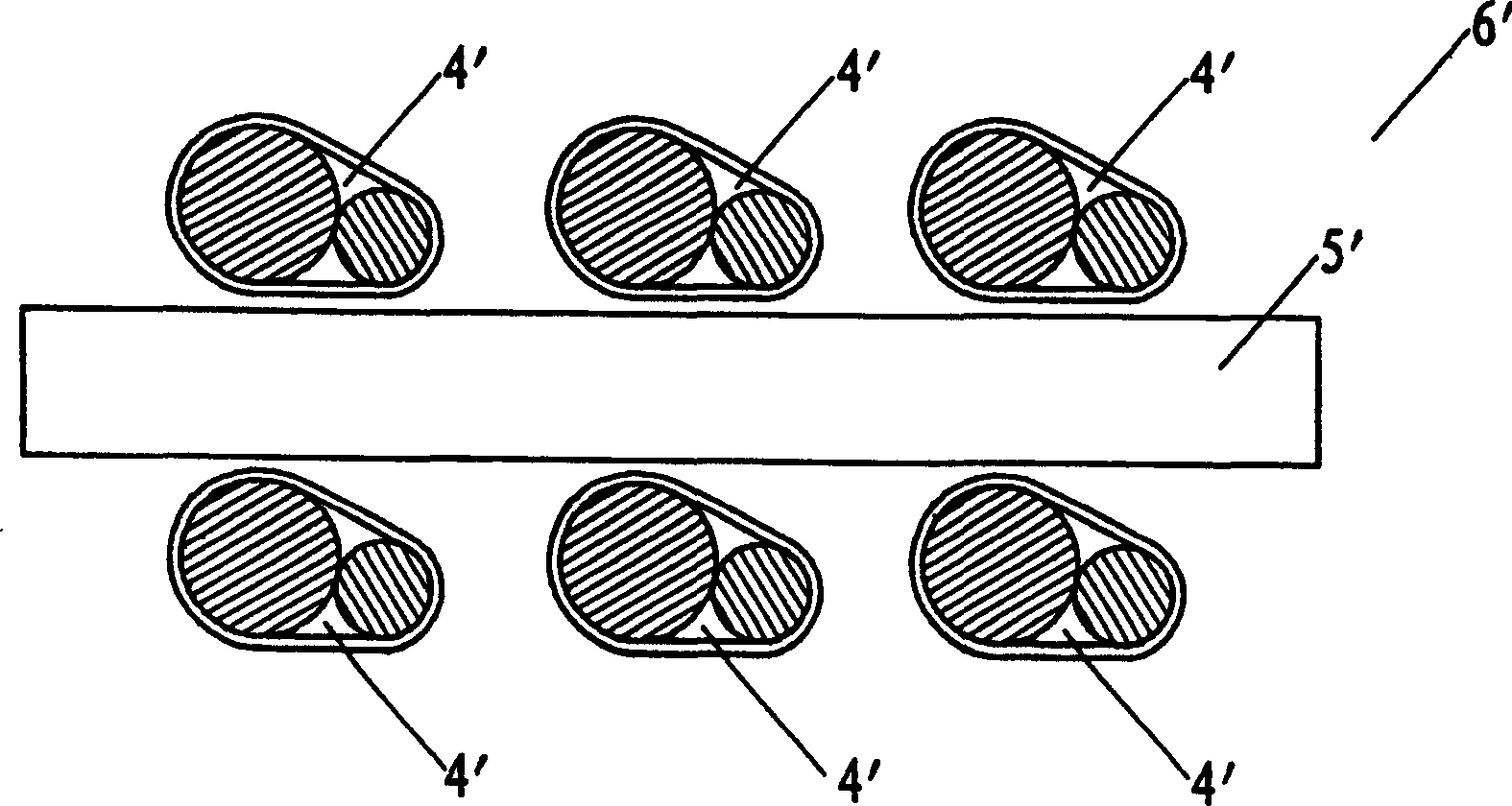

[0029] like Figure 4~7 As shown, the composite double auxiliary wire main auxiliary three wire triple helix filament 11 is a spiral tungsten wire spirally surrounded by a helical tungsten wire. The double auxiliary helical tungsten wire 5 formed by wires 1 and 2 in an elliptical helical shape is then wound around another tungsten wire called the main tungsten wire 6 which is formed by a helical helical tungsten wire 8 and forms a secondary helix. Coil-shaped composite primary and secondary helical tungsten wires 9 .

[0030] The diameters of the tungsten wires 1 and 2, which are called double auxiliary wires, are smaller than the diameter of another tungsten wire 6, which is called the main and auxiliary wires, which is wound in a helical shape.

[0031] During manufacturing, the following steps can be used:

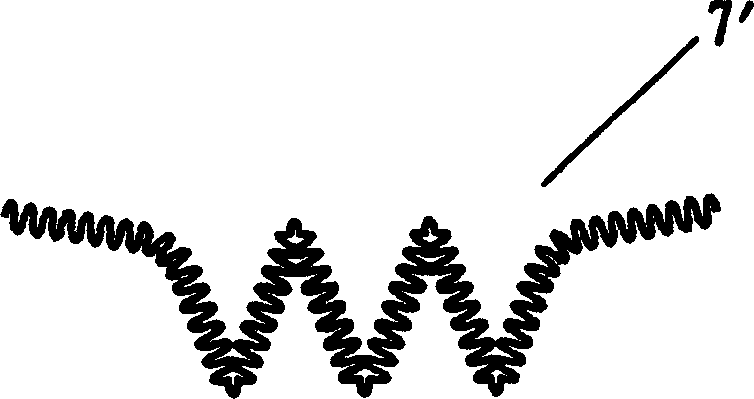

[0032] 1) Two thinner tungsten wires 1 and 2 with the same diameter (called double auxiliary wires) are spirally wound around two thin molybdenum core wires 3 and 4 w...

Embodiment 2

[0039] Similar to Example 1, the difference is that two tungsten wires 1 and 2 with different diameters and two thin molybdenum core wires 3 and 4 with different diameters are used during manufacturing. In addition, the temperature for high-temperature setting is 1450-1550° C., and the time is 20-25 minutes; the concentration of nitric acid and sulfuric acid is 60% and 97% respectively; the ratio of mixed acid is nitric acid: sulfuric acid: pure water = 1: 1.1: 1.4.

Embodiment 3

[0041] Similar to Example 1, the difference is that two tungsten wires 1 and 2 with different diameters and two thin molybdenum core wires 3 and 4 with the same diameter are used during manufacturing. In addition, the temperature for high-temperature setting is 1300-1450° C., and the time is 25-30 minutes; the concentration of nitric acid and sulfuric acid is 67% and 96% respectively; the ratio of mixed acid is nitric acid: sulfuric acid: pure water = 1: 1.3: 1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com