Porous brickwalk laying method

A technology for permeable paving and trails, which is applied to roads, roads, and paving surfaces paved with prefabricated blocks, which can solve problems such as non-load-bearing, airtight, and watertight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

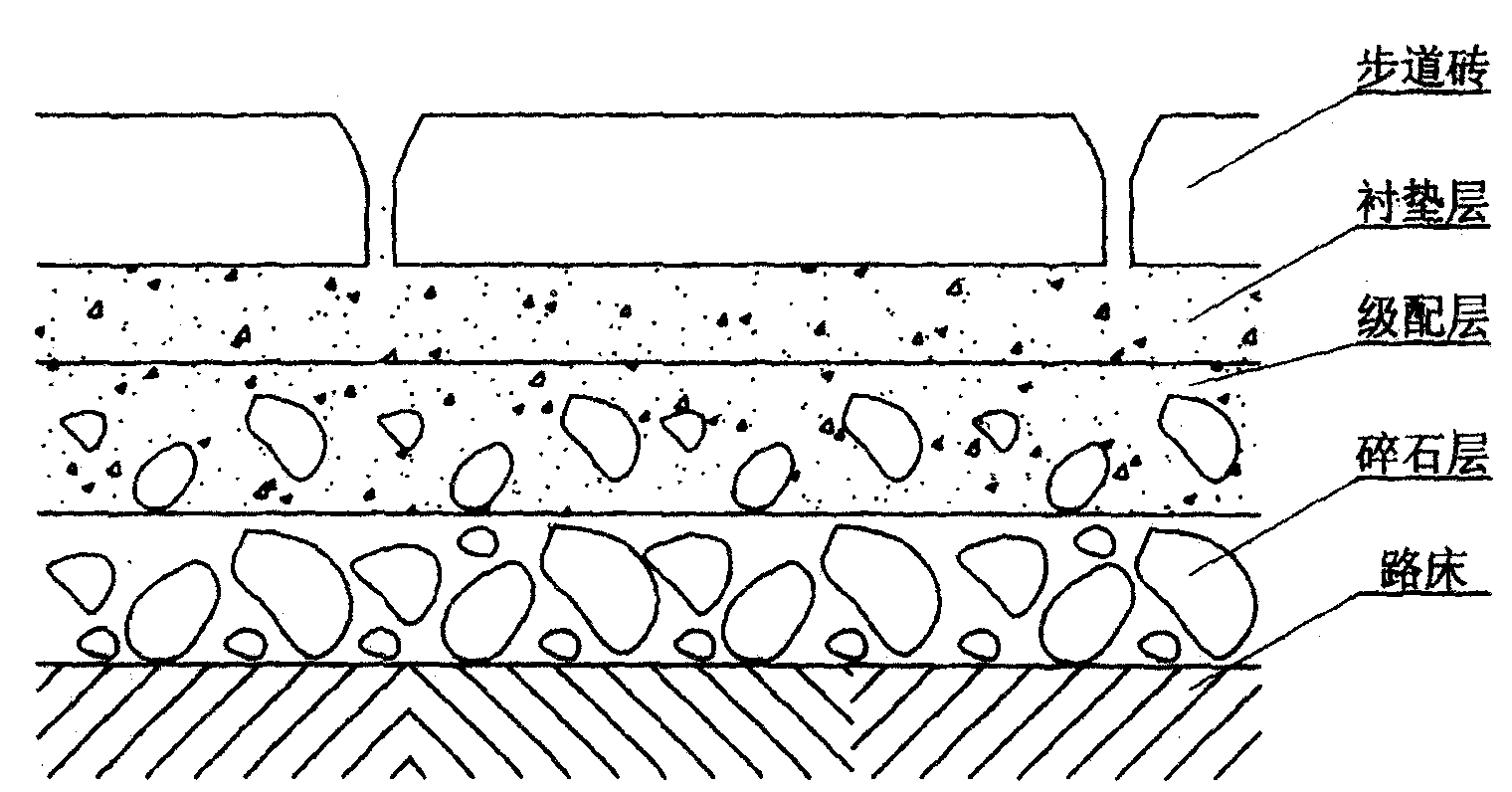

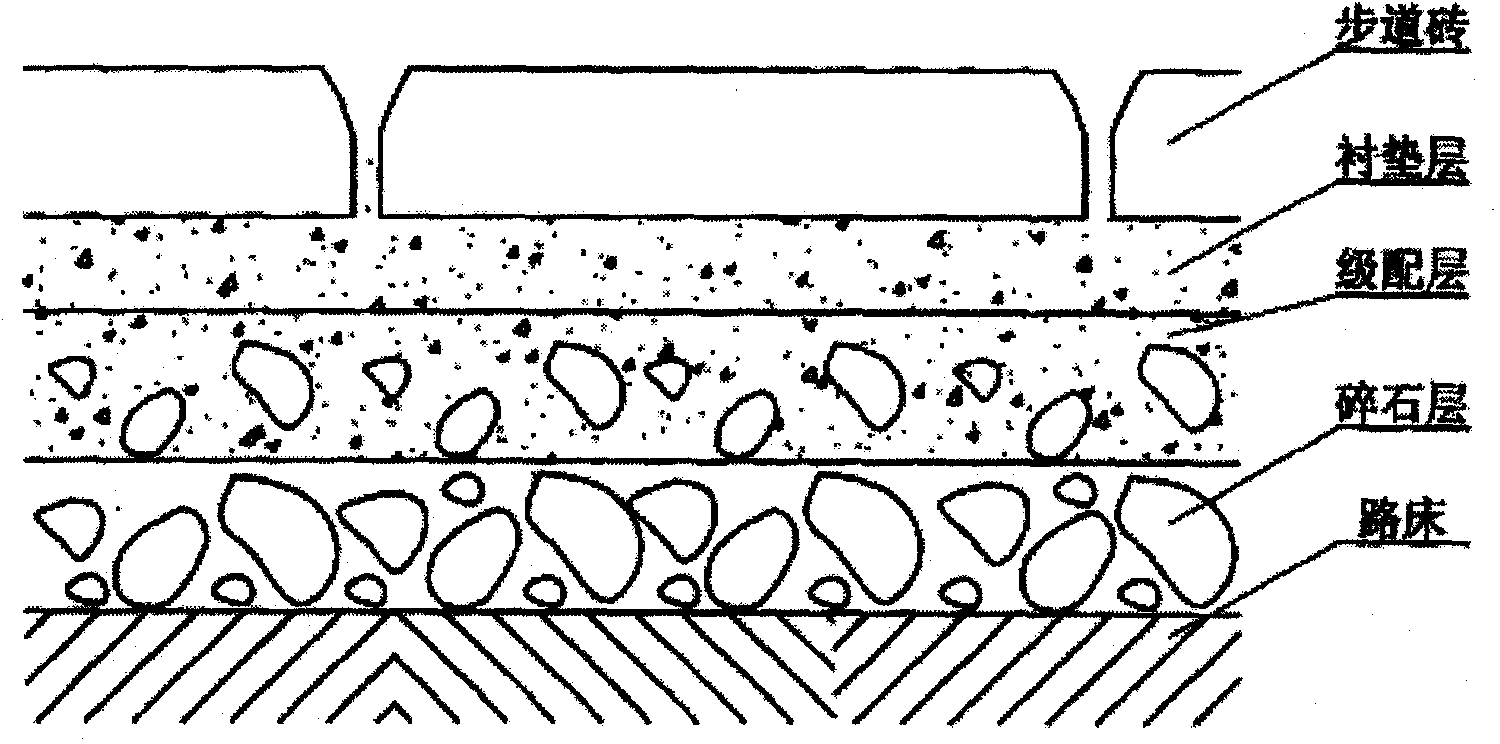

[0005] Specific implementation mode one: (see figure 1 ) This embodiment is achieved through the following steps: one, the original soil layer of the road bed is rammed or compacted with a rammer or a road roller; On the top, the paving thickness of the crushed stone is 30-200mm; 3. Laying the graded layer: lay the gravel and stone powder on the crushed stone layer, push it flat and then spray water for compaction, and the laying thickness of the graded layer is 10-200 mm. 100mm; 4. Laying the backing layer: After mixing the crushed stone and fine sand, spread it on the gradation layer, and sink it with water. The thickness of the backing layer is 10-50mm; The machine will tamp the backing layer, and then lay the pavement bricks, the thickness of the pavement bricks is 50-80mm. The average diameter of the gravel used in the crushed stone layer is 1-3cm or 2-4cm; the average diameter of the gravel in the graded layer is 0.1-2mm, and the particle size of the stone powder is 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com