Hollow-weave airbag

A tissue safety and bag-like technology, applied in vehicle safety arrangements, pedestrian/passenger safety arrangements, textiles, etc., can solve problems such as complex manufacturing processes, increased costs, and difficult folding, to reduce sudden changes, suppress opening, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

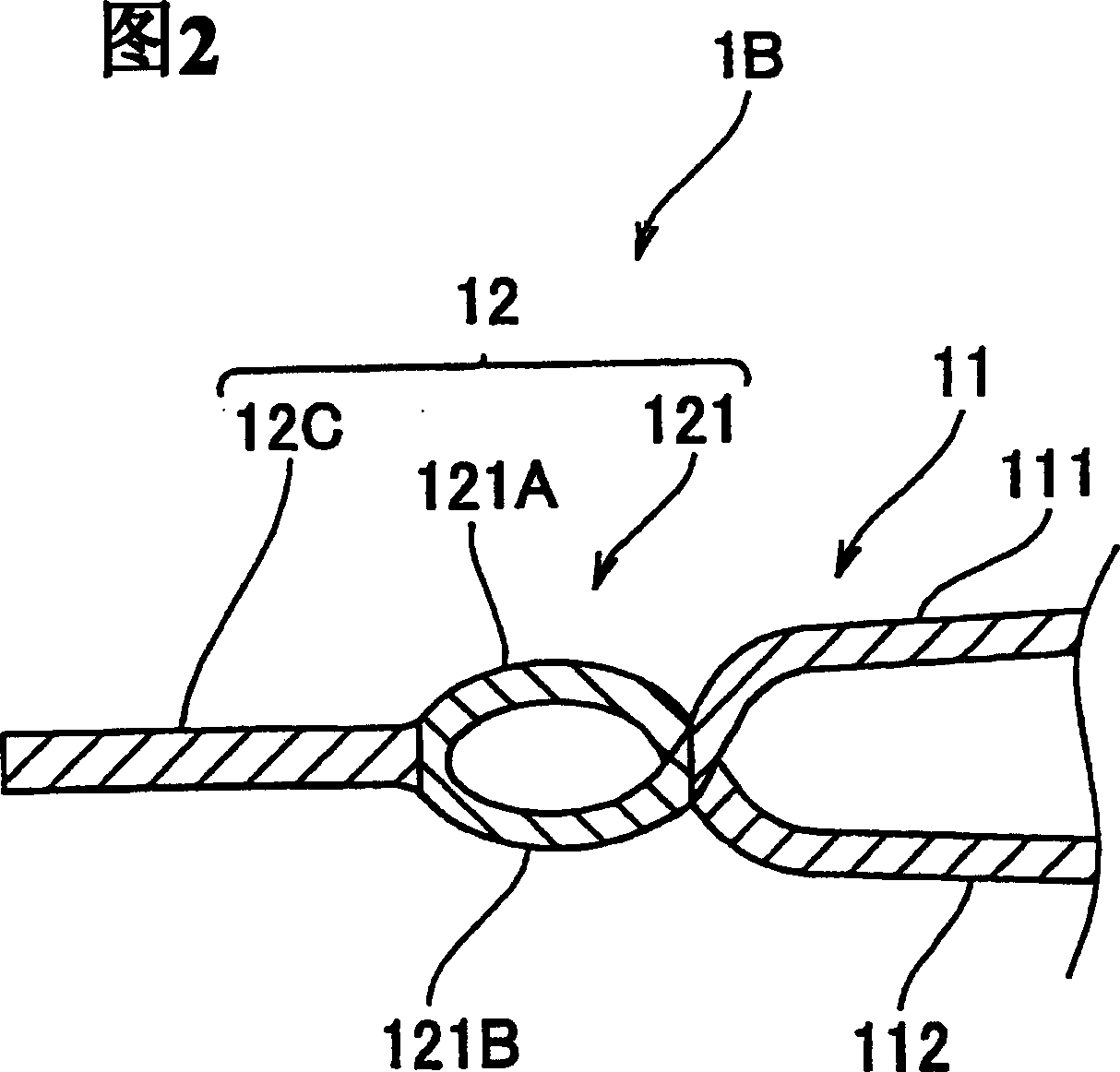

example 1

[0062] Examples 1 and 2 are examples of the first embodiment of the bag-shaped tissue airbag. In Example 1, in the tissue structure constituting the closing portion 12, the first tissue structure 12A adjacent to the airbag bag portion 11 is formed by 4 weft yarns. The 2 / 2 basket weave structure is formed, and the second weave structure 12B is formed by a 1 / 1 plain weave structure formed of 2 weft yarns adjacent to the side of the first weave structure 12A on the opposite side of the airbag bag portion. Also, in Example 2, in the weave structure constituting the closing portion 12, the first weave structure 12A adjacent to the air bag portion 11 is formed by a 2 / 2 basket weave structure composed of 4 weft yarns, and the second weave structure 12B is formed by A 1 / 1 plain weave structure formed of 4 weft yarns is formed adjacent to one side of the first weave structure 12A on the opposite side of the airbag bag portion. In addition, Examples 1 and 2 each have a third tissue stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com